What is the difference between rigid, flexible, and rigid-flex Multi-layer PCB?

As life improves and the technology of electronic products around us also advances, everyone will pursue higher-performance electronic equipment, followed by the demand for more complex and more adaptable PCBs. Among them, multi-layer PCB have the ability and function to adapt to complex designs. This category has three main types: rigid, flexible, and rigid-flex multilayer PCBs. Each type has unique characteristics, applications, and advantages. In this guide, we’ll examine the differences between these three types of multilayer PCBs.

Multi-layer PCB

Multi-layer PCBs consist of three or more layers of conductive material separated by insulating layers. These layers are laminated together to form a single cohesive unit. The main advantage of multilayer PCBs is the ability to support complex circuitry in a compact space, providing enhanced performance and reliability. Multi-layer PCBs are used in various applications, ranging from consumer electronics and medical devices to the aerospace and automotive industries. The choice between rigid, flexible, and rigid-flex multi-layer PCBs depends on the application’s specific requirements, including mechanical constraints, environmental factors, and electrical performance needs.

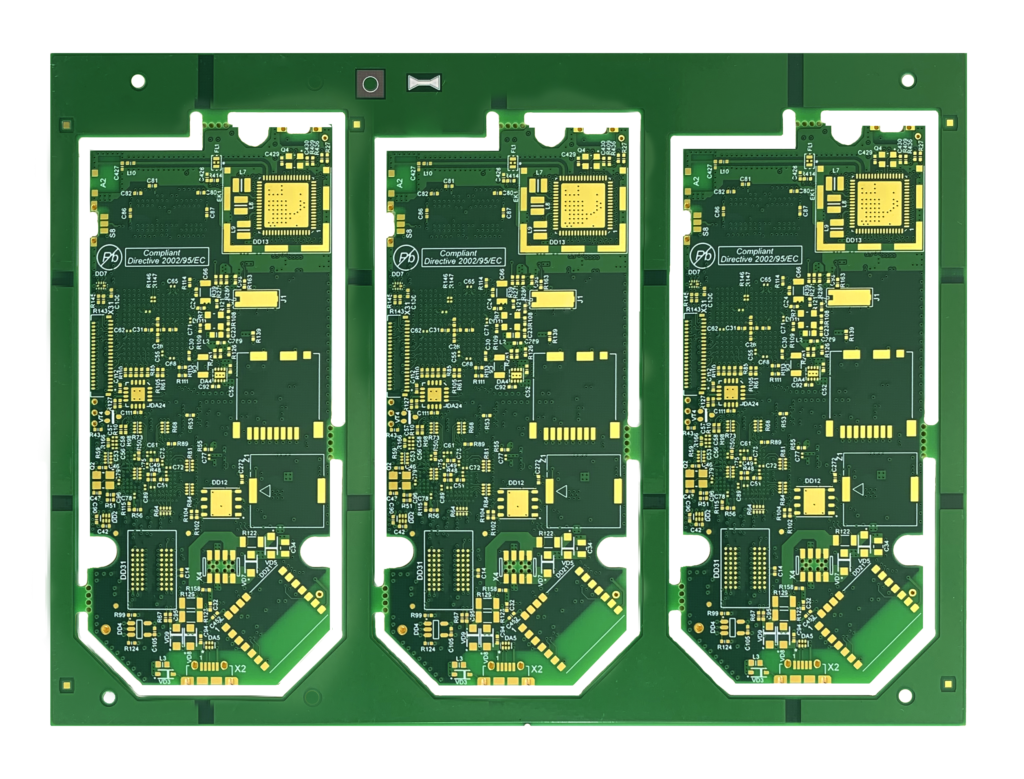

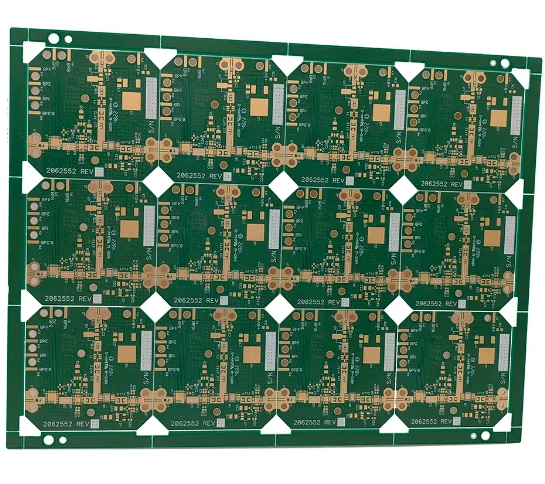

Structure and Application of Rigid Multilayer PCB

The most common type of PCB is rigid multi-layer PCB. These boards are inflexible and made from solid materials like fiberglass (FR4) to provide stability.

Manufacturers laminate copper and insulation materials to create a durable and strong circuit board that supports heavy components and withstands mechanical stress. They commonly use rigid multilayer PCBs in desktop computers, laptops, servers, and other fixed equipment where the board’s lack of flexibility is not an issue. Their advantage is that rigid multi-layer PCBs can withstand mechanical stress and vibration without damage and can accommodate high-density components, making them suitable for complex circuits. They are typically less expensive to manufacture than flexible or rigid-flex PCBs. What is lacking is the inability to bend or curve, limiting their use in applications where space is limited and a more adaptable circuit board is required.

Structure and application of flexible multilayer PCB

Designers create flexible multi-layer PCBs to bend without breaking. They use flexible substrates such as polyimide, allowing the boards to adapt to various shapes and fit into tight spaces. Therefore, this property makes them suitable for wearable electronics, smartphones, and tablets. They have the advantage of being able to bend, twist and fold to fit into unconventional spaces and are lighter than rigid PCBs, benefiting portable devices. The disadvantage is that the production process is more complex and costly than rigid PCB and cannot support the same high component density as rigid boards.

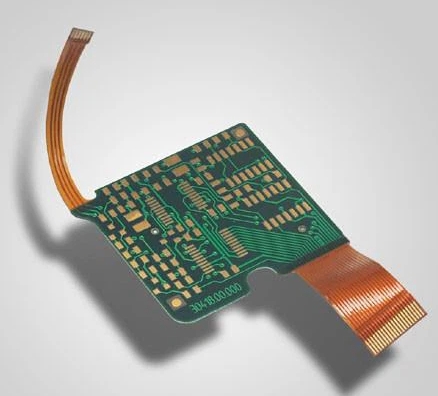

Rigid-flexible multilayer PCB

Rigid-flex multilayer PCBs combine the advantages of rigid and flexible PCBs. These boards have a multilayer flexible circuit substrate attached to one or more rigid boards. Advanced electronics use them where reliability and performance are critical, such as in military and aerospace applications, high-end consumer electronics, and medical devices. Combining the best properties of rigid and flexible PCBs makes them suitable for a wide range of applications while also reducing the overall size and weight of electronic components and increasing reliability due to fewer solder joints and interconnections. The only drawback is that the materials and manufacturing processes are more expensive than those of individual rigid or flexible PCBs and require longer production and manufacturing times.

Electrical performance comparison

When choosing between rigid, flexible, and rigid-flex multilayer PCBs, electrical performance must be considered. Each type offers different capabilities regarding signal integrity, impedance control, and thermal management.

Rigid multilayer PCBs typically provide excellent signal integrity due to stable construction and controlled impedance. You can easily integrate heat sinks and other thermal management solutions. They are ideal for high-frequency applications with precise impedance requirements. Flexible multilayer PCBs may have insufficient signal integrity due to their flexible nature and the possibility of bending. They can achieve controlled impedance but may require more complex design techniques.

Rigid-flex multilayer PCBs can provide good signal integrity with the added benefit of flexibility but require careful design to maintain performance. Combining the thermal management benefits of a rigid PCB with the adaptability of a flexible design also enables precise impedance control, making it suitable for complex high-frequency applications.

Find the one that suits you best

The choice between rigid, flexible, and rigid-flex multilayer PCBs depends on your application’s specific requirements. Rigid multilayer PCBs provide robustness and cost-effectiveness for fixed equipment, while flexible multilayer PCBs provide adaptability for compact and dynamic applications. Rigid-flex multilayer PCBs offer the best of both worlds, combining the durability and flexibility of advanced electronics.