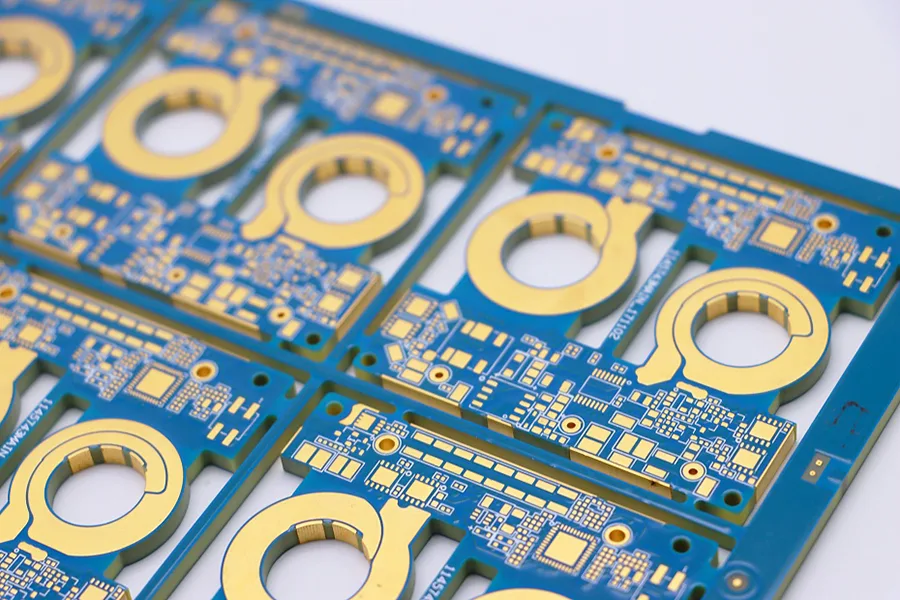

Double-sided PCB plays a pivotal role in many industrial applications. These boards offer greater routing flexibility by allowing components and traces on both sides of the board. For industries that demand compact designs and reliable connections, the Double-Sided PCB is a practical and efficient solution. Industrial environments often involve high voltages, mechanical stress, and extreme […]

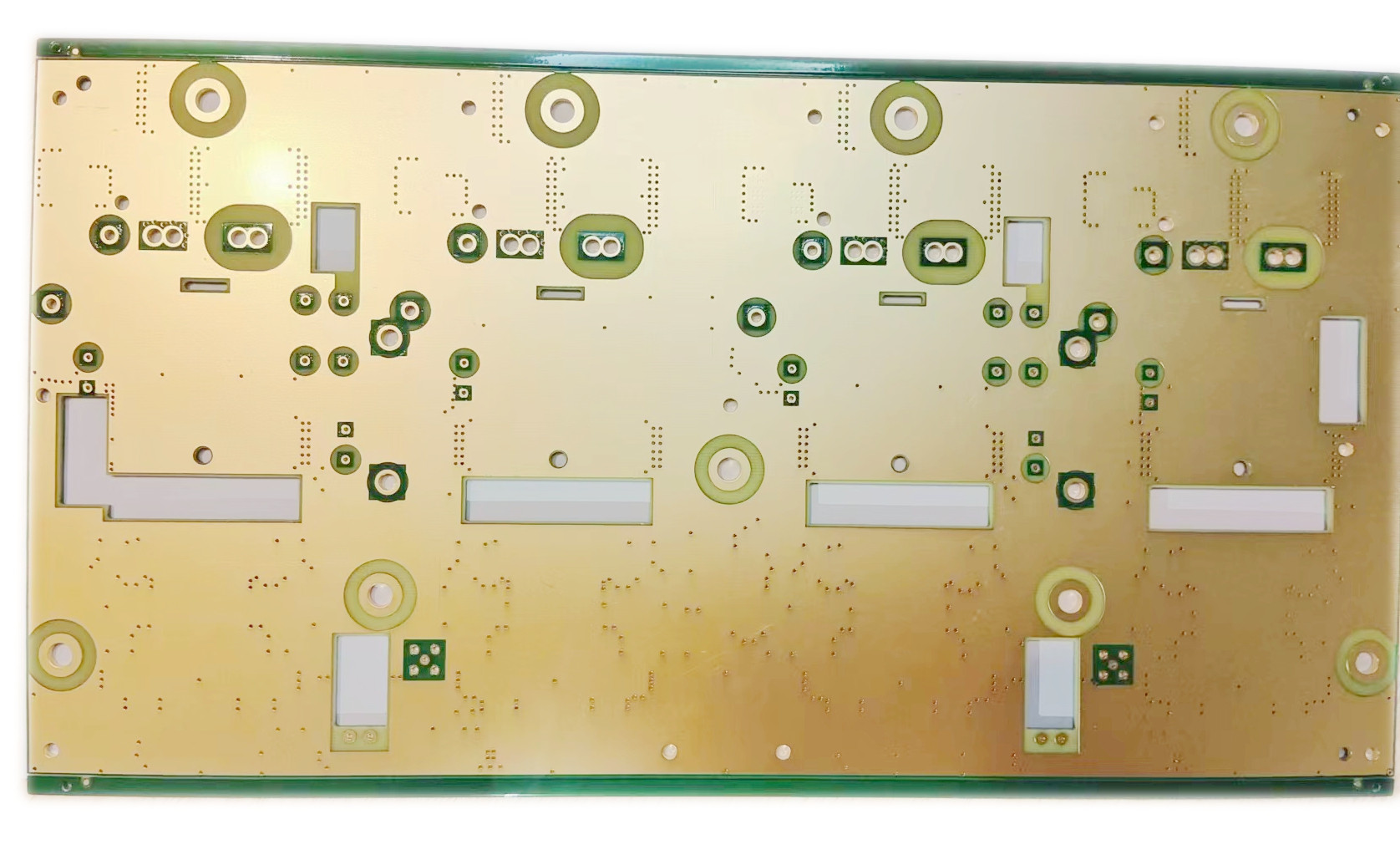

The Heavy copper PCB plays a vital role in reducing failure risks within power supply modules. These specialised printed circuit boards utilise thick copper layers to safely and efficiently handle high current loads. They serve as the backbone of many high-power electronic systems. Without the proper PCB design, power supply modules face increased risks of […]

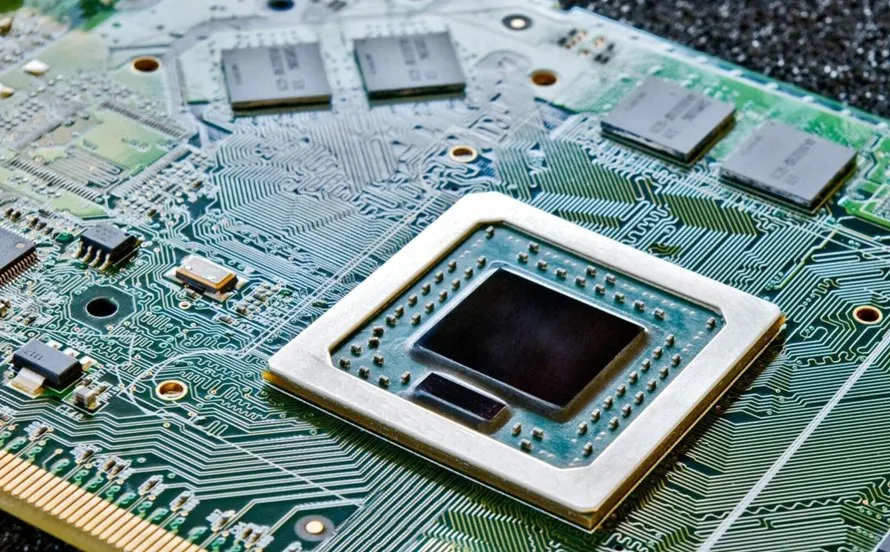

The design of an SSD PCB plays a critical role in determining both the performance and reliability of storage devices. The printed circuit board (PCB) acts as the foundation for all electronic components, including the NAND flash, controller, DRAM cache, and power management systems. Without well-engineered SSD PCBs, even the most advanced memory chips cannot […]

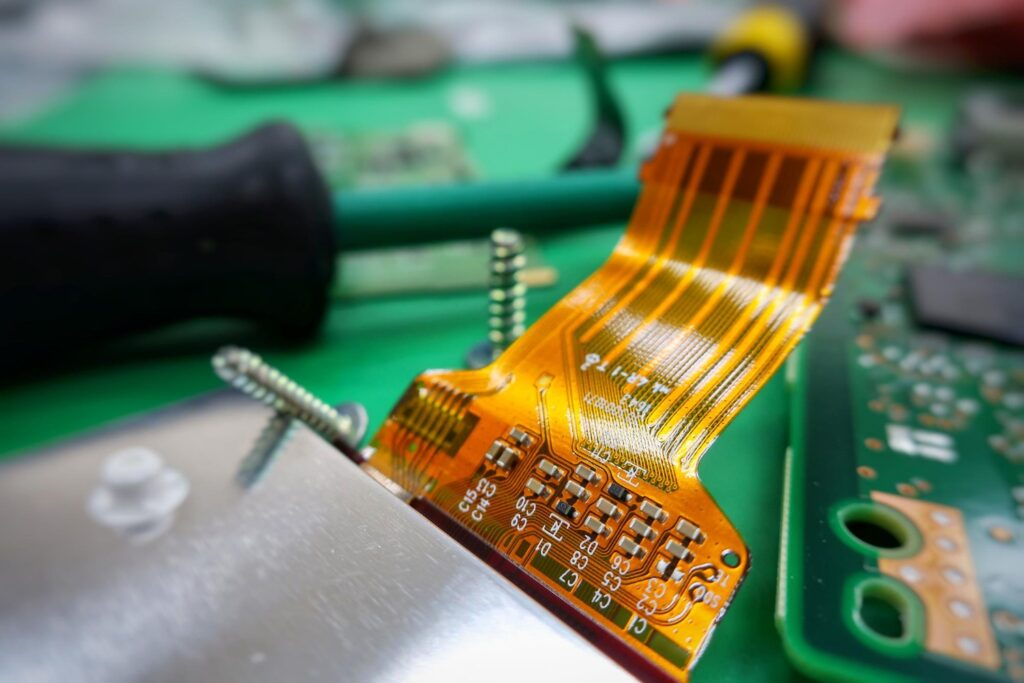

Poor routing during the design of rigid-flex PCB can lead to signal integrity issues, mechanical failures, and increased electromagnetic interference. Unlike traditional rigid printed circuit boards (PCBs), rigid-flex boards must work in a dynamic environment. Traces travel through flex and static areas, each with different stress distributions. Improper routing in the flex area may cause […]

As artificial intelligence continues to evolve rapidly, the demands on hardware are escalating. One critical piece in this equation is the HDI PCB. High-density interconnect printed circuit boards are uniquely positioned to address the challenges presented by AI’s need for speed, capacity, and compactness. AI processors require high-speed data transfer and minimal signal interference—demands that […]

When it comes to the performance and durability of Gold Finger PCB assemblies, surface plating isn’t just a technical detail—it’s a critical design decision. Engineers and OEMs often face a common choice between ENIG (Electroless Nickel Immersion Gold) and Hard Gold plating. While both serve the same function—protecting the contact edge of PCBs—their characteristics vary […]

The Set-Top Box PCB is the heart of any modern streaming device. It orchestrates every operation, from video decoding to network connectivity. As 4K and OTT streaming become the norm, the performance of your PCB defines the viewer experience. Gone are the days of basic cable; today’s set-top boxes demand power, efficiency, and seamless integration. […]

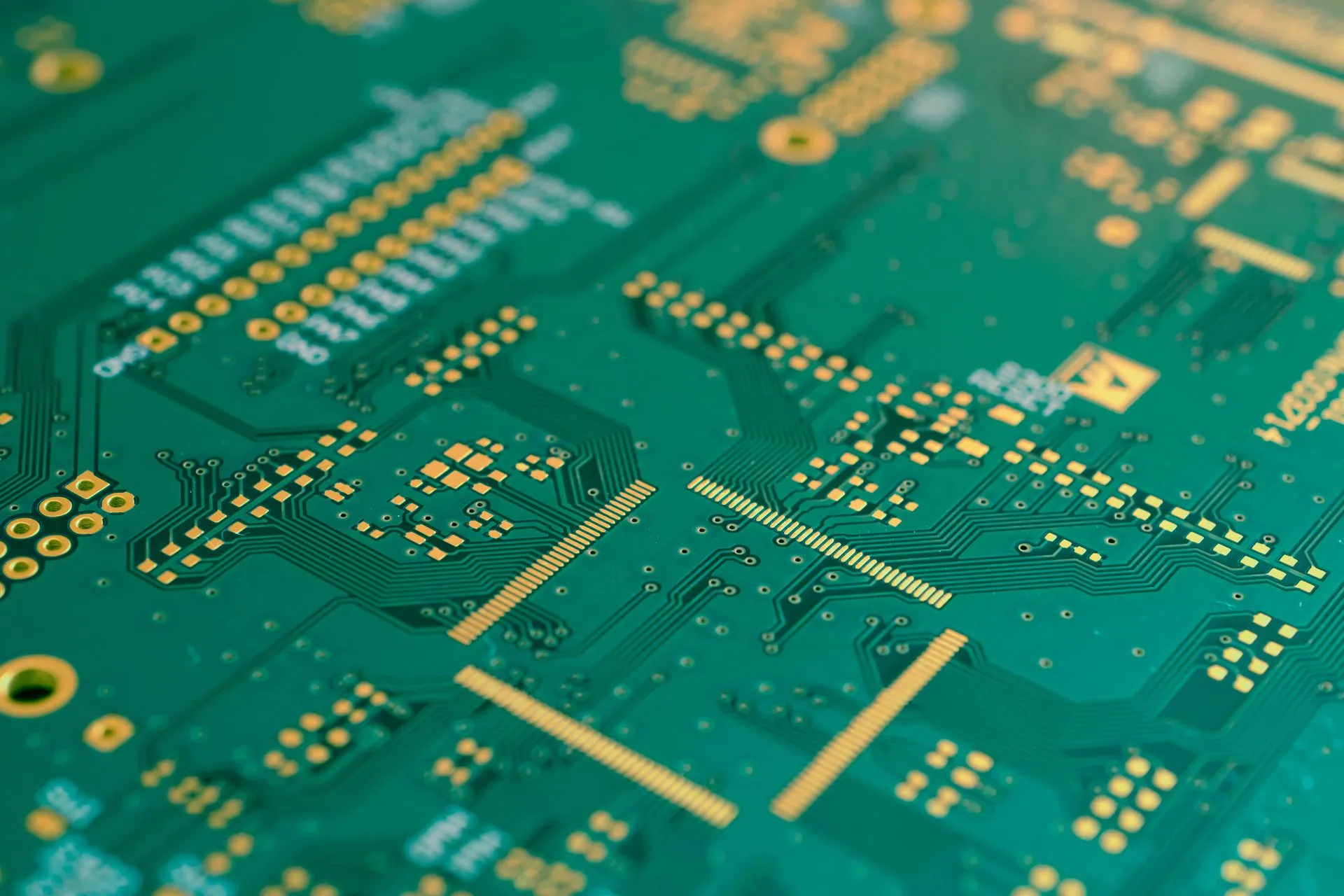

Have you ever wondered why most multilayer PCB have even more layers? The most common configurations are four, six, or eight layers. Many engineers usually choose even layers when designing multilayer PCBs because these even-numbered designs are more stable, cost-effective, and easier to manufacture. So why are even-numbered layers more stable than odd-numbered layers? Let’s […]

The base material can make or break performance when designing a reliable SSD PCB. As the demand for high-speed data storage grows, engineers and manufacturers face increasing pressure to select substrates that offer electrical stability, thermal endurance, and mechanical reliability. FR4, Polyimide, and BT Resin are the primary contenders in this arena. Each comes with […]

Heavy Copper PCB is critical in today’s high-power electronic applications, especially in power supply and conversion systems. These specialized circuit boards contain copper layers thicker than standard PCBs, typically over 3 oz/ft². This allows them to handle higher current loads and manage heat more effectively. These features make them ideal for converters, inverters, and power […]

.jpg)