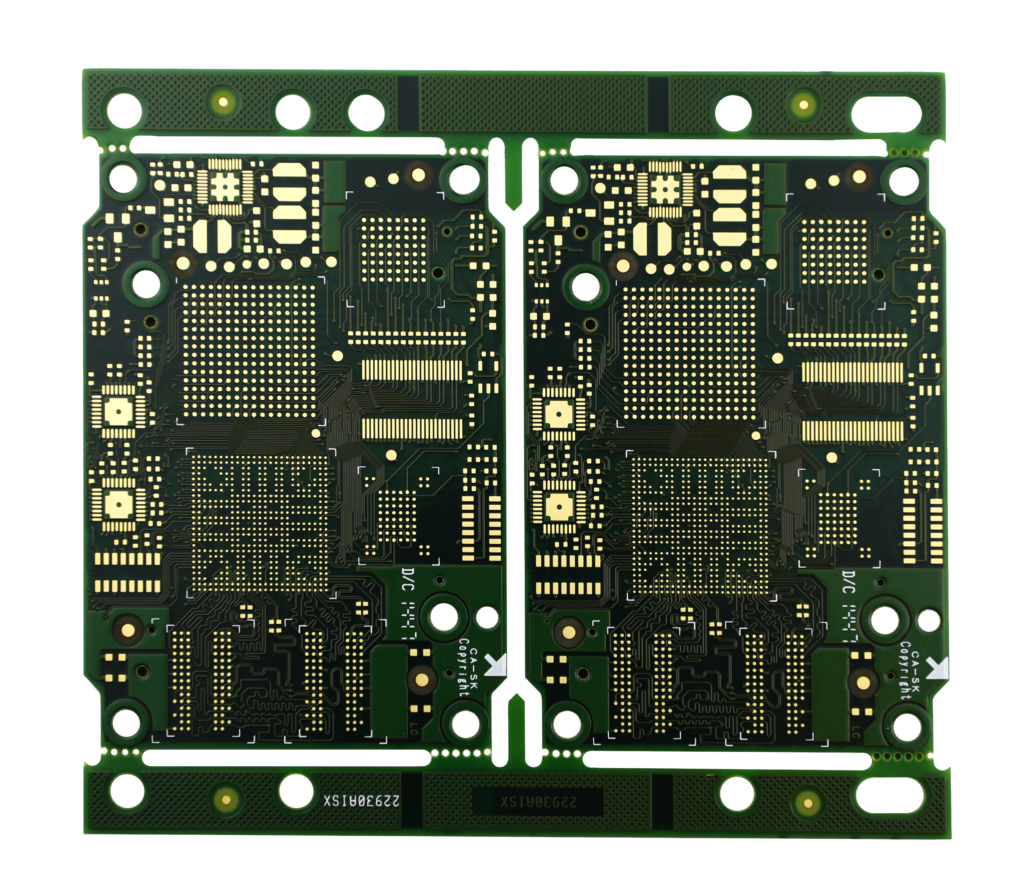

Methods to improve yield rate in 400G high speed PCB production

With the rapid development of the communications industry and data centers, the demand for 400G high-speed PCBs has surged. Achieving high yields in 400G high speed PCB production is critical for manufacturers to meet customer expectations. This guide will explore various methods to improve 400G high-speed PCB production yields.

Optimizing 400G high speed PCB manufacturability design

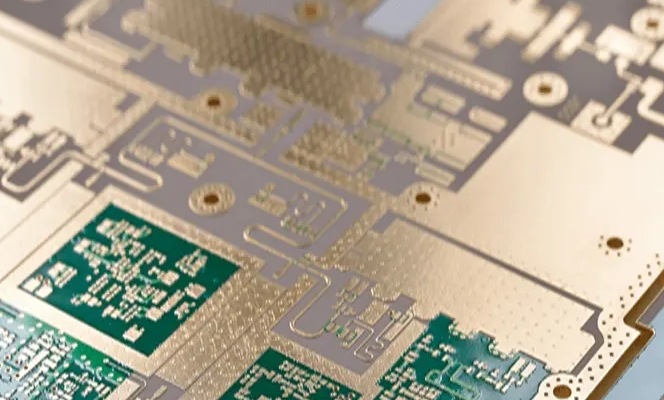

Optimizing manufacturability design is one of the methods to improve the yield rate of 400G high speed PCBs. We incorporate design for manufacturability (DFM) at the beginning of the design process to improve yield. We optimize layer stacking by carefully placing different layers to control impedance and reduce electromagnetic interference (EMI). Proper stack-up design can minimize signal attenuation and crosstalk, which are common problems at high frequencies. For 400G high-speed PCB, precise routing and via design are crucial. During the design process, we ensure traces have controlled impedance and no sharp corners or excessive via stubs while using micro vias or blind/buried vias instead of vias to improve signal integrity, reduce manufacturing complexity, and Employ effective thermal management in your design.

Choosing high-quality materials for 400G high speed PCB

The way to improve the yield of 400G high speed PCB production is also to choose high-quality materials. The materials used throughout PCB manufacturing, including substrate, copper, and solder masks, play an important role in the performance and reliability of the final product. We choose materials with stable, low dielectric constants to reduce signal delay and dispersion, thereby maintaining signal integrity over long distances. In addition, we select materials that preferably have a high glass transition temperature (Tg) and a low coefficient of thermal expansion (CTE). These materials maintain dimensional stability and mechanical integrity under high thermal loads, thereby increasing overall reliability and throughput. High-quality laminates like Rogers RO4000 or RO3000 series, Isola IS620, and similar materials support high-speed signal transmission while minimizing distortion.

Implement advanced detection technology

The yield rate of 400G high-speed PCBs can also be improved by implementing advanced inspection techniques. 400G high-speed PCBs operate at extremely high frequencies, so even the smallest defects easily affect them. We use AOI systems with high-resolution cameras and sophisticated algorithms to identify even the tiniest defects during inspection. X-ray inspection technology inspects the PCB’s hidden features and internal structure. In this type of PCB, where high component density and complex multi-layer structures are common, X-ray inspection can reveal voids, solder bridges, and other subsurface defects that AOI might miss.

Enhance welding process

In other aspects, we will enhance the welding process of 400G high-speed PCBs to improve yield and use high-quality, fine-grained solder paste to ensure better adhesion and reliability of solder joints. Printing technology reduces the possibility of bridging, insufficient solder, or solder balls. In addition, we also use reflow soldering technology to maintain precise heat distribution.

Utilizing a convection reflow oven with multiple heating zones allows for precise control of temperature gradients, ensuring each solder joint reaches the optimal temperature for proper reflow without damaging sensitive components. Wave soldering or selective soldering techniques are typically used for through-hole components. A consistent temperature is maintained throughout the welding process, and implementing a real-time temperature monitoring system enables precise control of welding parameters.

Strengthen process control

In addition, we will strengthen process control to improve yield. For this, we will implement SPC, which involves using statistical methods to monitor and control the manufacturing process. By analyzing data at each production stage, manufacturers can identify trends before they lead to major defects, changes, and potential problems. SPC helps maintain consistent quality and allows for proactive adjustments to processes. Ensure that you train all personnel involved in the manufacturing process well and that they adhere to standardized procedures.

Achieve high yield in production

Improving the yield rate of 400G high-speed PCB production includes optimizing manufacturability design, implementing advanced detection technology, strengthening process control, and other technologies. High yields reduce production costs and ensure that manufacturers can meet market demand and maintain a competitive advantage.