What are the risks of thermal expansion for 2 layer TG170 pcb?

Thermal expansion is a key factor when manufacturing 2 layer TG170 PCB. As devices become more complex and power density increases, the effect of thermal expansion on PCBs becomes critical to ensure reliability and functionality. In this blog post, we’ll share with you the specific risks associated with thermal expansion of 2-layer TG170 PCBs, and why choosing the right materials and design methods is so important for high-performance electronics.

What is the thermal expansion of 2-layer TG170 PCB?

Thermal expansion of a 2 layer TG170 PCB is an important aspect of its performance, especially in environments where the PCB is exposed to varying temperatures. The coefficient of thermal expansion is a key property of PCB materials and indicates how much the material expands per unit length for each degree change in temperature. For TG170 PCB, the CTE usually varies in different x, y, and z directions of the material. In-plane CTE values are generally lower compared to the z-axis. Typically, TG170 PCB materials have CTE values of approximately 13 to 18 ppm/°C in the x and y directions and can be significantly higher in the z-direction, typically in the 70 ppm/°C range. This difference is due to the layered structure of the PCB and the different properties of the copper and dielectric materials used in the board.

Mechanical stress and strain

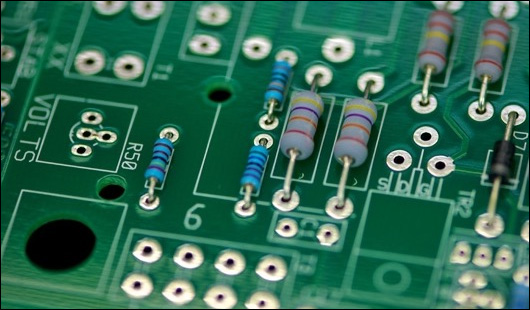

One of the major risks associated with thermal expansion of 2-layer TG170 PCBs is the creation of mechanical stresses and strains within the board and its mounted components. These stresses are caused by differences in expansion rates between the PCB material and the various metal components and traces attached. This mechanical strain is particularly important for PCBs with a glass transition temperature of 170°C, where the material’s behavior changes significantly at higher temperatures. Mechanical stress caused by thermal expansion can compromise the reliability of electronic components. For example, fragile components such as ceramic capacitors or glass diodes are particularly susceptible to cracking under pressure.

Impact on Through Holes and Plated Through Holes

Another aspect of the 2 layer TG170 PCB that is susceptible to thermal expansion is its vias and plated through holes (PTH). An expansion mismatch between copper plating and substrate material can cause cracks around vias and holes, disrupting electrical pathways and leading to device failure. Under repeated thermal cycling, stresses caused by differential expansion can cause fatigue in the copper plating of vias and PTHs. This can cause cracks to form in the copper itself or between the copper and the PCB substrate. Such failures can compromise the electrical integrity of the PCB, potentially causing open circuits or intermittent connections that can impair the device’s functionality.

Design and Layout Considerations

Well, to mitigate the risks associated with thermal expansion of a 2 layer TG170 PCB we need to consider the design and layout carefully. First and foremost, selecting materials with compatible thermal expansion (CTE) coefficients is critical. For TG170 PCBs, ensuring that the core and laminate materials’ CTE values closely match the copper layers’ CTE values can significantly reduce stresses caused by thermal expansion. Designers should layout components to evenly distribute heat on the PCB to avoid local thermal gradients. You can accomplish this by spreading the heating components and using cooling holes to dissipate the heat. Additionally, thicker copper helps reduce stress and strain on the traces during thermal expansion and contraction.

Testing and Quality Assurance

Rigorous testing and quality assurance are critical to managing the risks of thermal expansion of 2-layer TG170 PCBs. Thermal cycling testing is the basis for evaluating the durability and structural integrity of TG170 PCBs under thermal stress conditions. These tests can repeatedly cycle through extreme temperature changes from very low to high. During this process, you can evaluate the durability of materials and the stability of vias, solder joints, and conductive traces well.

These tests involve exposing PCBs to high humidity and heat for extended periods of time while monitoring for any signs of degradation. Humidity accelerates many failure mechanisms, especially when combined with high temperatures. Mechanical stress tests such as bending or twisting can be employed further to evaluate a PCB’s robustness under thermal expansion conditions.

Protects 2-layer TG170 PCB from thermal expansion

While 2-layer TG170 PCBs can withstand higher temperatures, managing the risks associated with thermal expansion is critical to ensuring long-term reliability and performance. We mitigate these risks by using thermal expansion mechanisms, thoughtful design and layout strategies, and choosing the right materials during manufacturing.