What are the electrical properties of ultra low loss PCB materials?

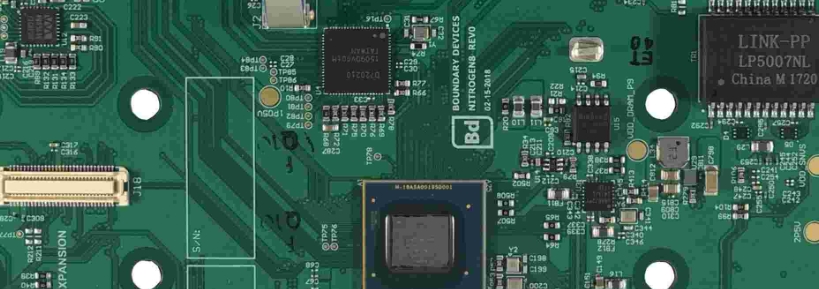

During the PCB manufacturing process, the choice of substrate material will greatly affect the final product’s overall performance. This effect is important for applications requiring signal integrity and high-frequency performance requirements. Ultra low loss PCB is very suitable for these demanding applications. In this article, we will discuss the basic electrical properties of ultra low loss PCB materials and understand how these materials provide advantages in high-frequency performance electronic applications.

Dielectric constant of ultra low loss PCB materials

Ultra low loss PCB are made of materials that minimize dielectric losses, which can degrade signal integrity, especially at higher frequencies. The dielectric constant of these materials typically ranges from 2 to 4, which is lower than typical FR-4 materials, averaging about 4.5. This lower dielectric constant is advantageous because it reduces signal propagation delays and lowers the transmission line’s characteristic impedance. One of their most critical attributes is their ability to maintain stability over various frequencies and environmental conditions. The dielectric constant of materials such as Rogers RO3003™ and RO4003C™ and Taconic RF-35 and TLF-35 remains stable with frequency, temperature, and humidity changes.

Dissipation Factor of Ultra Low Loss PCB Materials

Maintaining a low loss factor in ultra low loss PCB materials can better optimize the performance and reliability of high-frequency electronic circuits. Low Df helps minimize insertion loss in RF applications, enhancing signal integrity and reducing power consumption. Typically, ultra-low-loss materials have a loss factor in the range of 0.001 to 0.004, which is lower than the loss factor of traditional materials such as FR-4, which can range up to 0.02. This difference highlights the ability of ultra-low-loss materials to maintain signal strength and purity over a wide frequency range and varying environmental conditions.

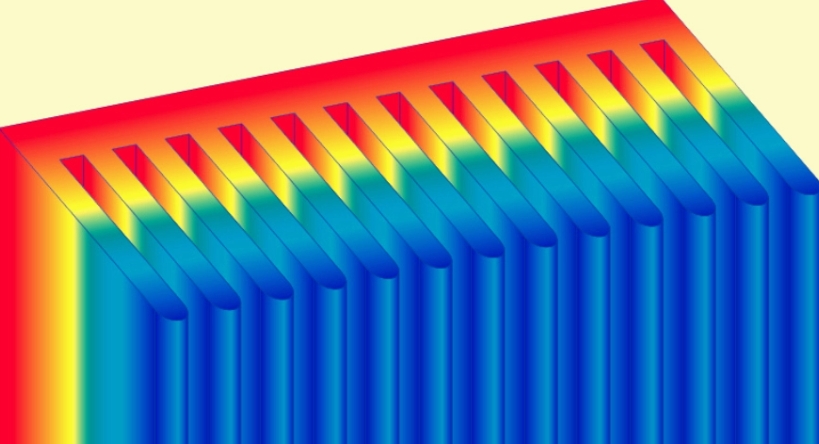

Thermal conductivity and performance

The thermal conductivity of ultra-low-loss PCB materials is typically between 0.3 and 3 W/m·K, which is higher than that of standard materials such as FR-4, which typically has a thermal conductivity of about 0.25 W/m·K. This enhanced thermal performance is critical for high-frequency and high-power applications such as RF and microwave communications, high-speed digital applications, and power amplifiers. Its thermal performance depends not only on the inherent thermal conductivity of the material, but also on the overall design and assembly of the PCB. For example, the thickness of the copper layer, the presence of thermal vias, and the circuit’s layout all affect how heat is distributed and dissipated on the PCB.

Effect of moisture-absorbing PCB materials

In materials for ultra-low loss PCBs, the main issue related to moisture absorption is changes in dielectric properties. Moisture inherently increases a material’s dielectric constant (Dk), which can cause unpredictable changes in impedance and signal propagation speed. This change can lead to signal reflections, loss of signal integrity, and increased signal attenuation for high-frequency applications. This is especially harmful in RF and microwave circuits. And ultra-low-loss PCB materials minimize moisture absorption and its associated effects. Materials such as PTFE composite are hydrophobic have very low moisture absorption, and are usually used in environments where exposure to moisture is unavoidable.

Electromagnetic interference processing

Electromagnetic interference (EMI) can degrade the performance of electronic circuits, especially in environments with dense electronic applications. Ultra low loss PCB materials can provide excellent electromagnetic shielding capabilities. Materials with inherently low dielectric losses and high thermal stability, such as Rogers RO4003C™ and Taconic TLF-35, exhibit beneficial EMI shielding properties, thereby reducing circuit Susceptibility to external electromagnetic noise. For industries where EMI can severely impact functionality, ultra-low loss PCBs offer a powerful solution.

Advantages of ultra-low loss PCB materials

Ultra-low loss PCB materials offer various favorable electrical properties, including low dielectric constant and dissipation factor, high thermal conductivity, minimal moisture absorption, excellent frequency stability, and excellent EMI handling capabilities. These make them the ideal choice for today’s high-performance applications. The best choice for performance electronics.