Using Aluminum Oxide PCB to Improve High-Speed Data Transmission

In the digital information age, high-speed data transmission is critical to powering various electronic devices and communication systems. Many manufacturers are turning to aluminum oxide pcbs to meet the growing demand for faster and more reliable data transmission. This guide explores how aluminum oxide PCB revolutionizes high-speed data transmission, enhancing performance, reliability, and efficiency.

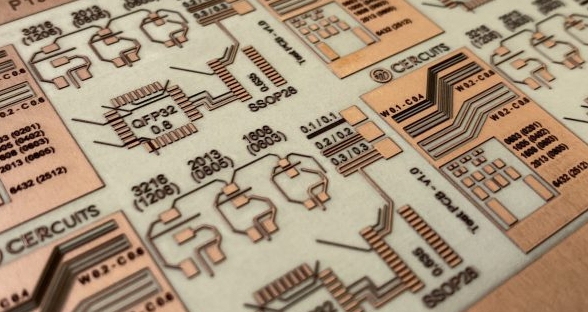

Enhance signal integrity using aluminum oxide PCBs

Using aluminum oxide PCBs offers several advantages in enhancing signal integrity, especially in high-frequency and high-power electronic applications. Aluminum oxide has excellent thermal conductivity, many times higher than traditional PCB materials such as FR-4, and can effectively dissipate the heat generated by electronic components. Additionally, alumina PCBs have excellent electrical insulation properties, making them suitable for high-voltage and high-power applications. This allows high-frequency signals to be transmitted with minimal distortion, ensuring high integrity and reliability in electronic circuits.

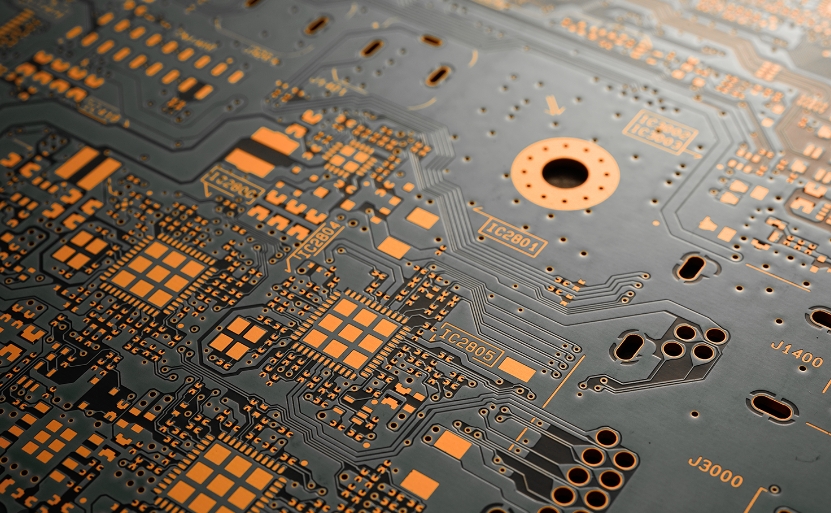

Aluminum oxide PCB optimizes transmission line characteristics

Alumina PCBs are also known for optimizing transmission line characteristics in high-frequency electronic applications. They can precisely control transmission line characteristics, allowing designers to achieve optimal impedance matching and signal propagation in high-speed data transmission systems. By carefully adjusting the geometry and layout of transmission lines, impedance mismatches and signal reflections can be minimized, thereby increasing data transmission efficiency and reducing electromagnetic interference (EMI). This level of control and accuracy is therefore critical to the reliability and performance of high-speed communications systems.

Reduce crosstalk and noise in high-speed data transmission systems

Crosstalk and noise are significant issues in high-speed data transmission because they can degrade signal quality, compromise data integrity, and cause communication errors. Aluminum oxide PCBs help mitigate these challenges by providing excellent isolation between signal traces, minimizing the risk of crosstalk and interference. In addition, the high thermal conductivity of aluminum oxide helps dissipate the heat generated by high-speed signals, further reducing the risk of signal attenuation due to thermal effects. By minimizing crosstalk and noise, aluminum oxide PCBs enable more robust and reliable data transmission in complex electronic systems.

Improved thermal management for high-speed data transmission

Thermal management is critical for high-speed data transmission systems, as excess heat can reduce signal integrity and reliability. Aluminum oxide PCBs have enhanced thermal stability, helping to maintain consistent electrical performance across varying temperature conditions. Aluminum oxide has a high melting point and can withstand high temperatures without significant degradation. It is suitable for use daily in high-temperature environments and high-speed data transmission systems. Additionally, Aluminum Oxide PCBs effectively dissipate heat across the PCB surface, helping to even out temperature gradients and prevent localized hot spots. Aluminum oxide’s high thermal conductivity helps quickly transfer heat from heat-generating components to areas of the PCB with lower thermal resistance, promoting uniform temperature distribution and reducing the risk of thermal stress-induced failures.

Achieve miniaturization and high-density integration

Alumina PCB’s compact size and high-density integration capabilities make it ideal for small electronic devices and high-speed data transmission applications with limited space. As manufacturing technology advances, designers can pack more components and signal traces into smaller PCB footprints, resulting in higher data transfer rates and greater system efficiency. Because of its excellent dimensional stability and precision, alumina has a low coefficient of thermal expansion (CTE), which means it experiences minimal dimensional changes with temperature. This feature ensures that the PCB remains stable and maintains its shape and size even under harsh operating conditions, allowing for precise alignment of components and fine-pitch routing of traces.

Ultimately

The signal integrity, optimized transmission line characteristics, and thermal management features provided by Aluminum Oxide PCBs make them ideal for high-speed data transmission. Therefore, alumina PCB enables faster, more reliable, and more efficient data transmission in telecommunications, automotive, aerospace, or consumer electronics.