Aluminum PCB in Consumer Electronics: Enabling Slimmer Designs

Consumer electronics have undergone significant changes in recent years, with many manufacturers offering slimmer designs without compromising performance. One key technology driving this development is aluminum PCB. This guide will explore how aluminum PCBs revolutionize consumer electronics by enabling thinner designs and superior performance.

Learn about aluminum PCB

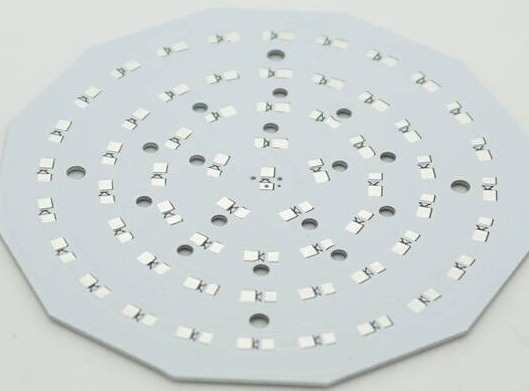

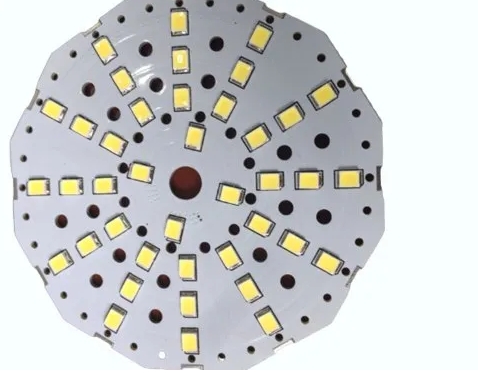

We make aluminum PCBs with an aluminum base layer instead of traditional materials such as fiberglass or epoxy. Aluminum’s high thermal conductivity can effectively dissipate the heat generated by electronic components, preventing overheating and ensuring optimal performance and reliability. This feature is essential in high-power applications such as LED lighting, power supplies, and automotive electronics. Secondly, aluminum PCBs have excellent electrical properties, and the metal core provides enhanced rigidity and stability, reducing the risk of mechanical failure and improving signal integrity. This makes aluminum PCBs ideal for high-frequency operation applications, such as radio frequency (RF) equipment, microwave communications systems, and power amplifiers.

Advantages of Aluminum PCB in Consumer Electronics

Aluminum PCBs offer several advantages when used in consumer electronics. Their excellent thermal conductivity effectively dissipates the heat generated by electronic components, ensuring optimal performance and longevity of devices such as smartphones, laptops, and tablets. Secondly, aluminum PCB provides excellent electrical performance due to its stable structure and low impedance characteristics. This enables reliable signal transmission and reduces electromagnetic interference, improving consumer electronics devices’ overall performance. Additionally, aluminum PCBs are lightweight and compact, ideal for portable electronics such as wearable devices, digital cameras, and handheld game consoles. Their lightweight properties can reduce the device’s weight, improving portability and user experience.

Thermal Management of Aluminum PCB

Aluminum PCB construction with a metal core facilitates efficient heat dissipation, allowing heat to be evenly distributed across the PCB surface and dissipated into the surrounding environment. Aluminum PCBs help maintain optimal operating temperatures by efficiently transferring heat from critical components such as CPUs, GPUs, power amplifiers, and voltage regulators. This ensures stable performance and extends the life of electronic devices, even under heavy load or extended use. Additionally, aluminum PCBs increase reliability by reducing thermal stress on components. Heat can cause materials to expand and contract, causing mechanical stress and potentially damaging solder joints or component connections. The thermal management features of aluminum PCBs can reduce the effects of thermal cycling, reduce the risk of mechanical failure, and improve the overall durability of electronic devices.

Applications in consumer electronics

Due to its many advantages over traditional PCBs, various consumer electronics products widely use aluminum PCBs. One of the main applications is in LED lighting fixtures, where aluminum’s high thermal conductivity helps dissipate the heat generated by the LED chips. Another common application is smartphones and tablets. Aluminum PCBs have excellent thermal management capabilities, helping to dissipate heat generated by processors, batteries, and other components. In addition, aluminum PCBs are used in audio equipment such as amplifiers and sound systems, and their excellent thermal conductivity ensures optimal performance and reliability, even during long periods of high-volume use.

Promote innovation in consumer electronics products

Aluminum PCBs are essential in driving innovation in consumer electronics due to their unique properties and functionality. A key aspect in which they contribute to innovation is the ability to design more compact and lightweight devices. The lightweight nature of aluminum PCBs enables manufacturers to create thinner, more portable products, driving innovation in the form and aesthetics of consumer electronics such as smartphones, tablets, and laptops. In addition, promotes the development of high-performance electronic devices by providing efficient thermal management solutions. Aluminum’s superior thermal conductivity helps dissipate the heat generated by electronic components, allowing powerful processors, GPUs, and other elements to be integrated without overheating. This enables performance innovation, allowing the device to easily handle demanding tasks such as gaming, video editing, and multitasking.

Embrace thinner, more efficient electronics

Aluminum PCBs drive the evolution of consumer electronics toward slimmer, more efficient designs by providing superior thermal management capabilities and enabling compact form factors. Aluminum PCBs would allow manufacturers to push the boundaries of innovation and deliver products that meet the needs of today’s tech-savvy consumers