The Robust Nature of 2 layer 3OZ pcb

In PCB design, the basis of robustness lies in the robust design of the PCB. This article will tell you about the superior strength and robustness embedded in 2 layer 3OZ PCB. As the demand for high-performance electronics increases, the ruggedness of 2 layer 3OZ PCBs becomes critical. Continuous research and improvements make the 2 layer 3OZ PCB a solid foundation for cutting-edge electronic applications.

2-Layer 3OZ PCB Ruggedness: The Significance of Copper Weight

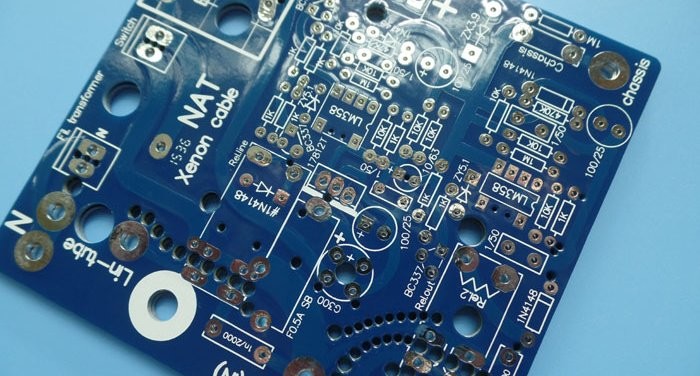

The sturdiness of a 2 layer 3OZ pcb is closely related to the importance of copper weight. Copper weight refers to the thickness or mass of the copper layer applied to the PCB substrate, usually measured in ounces per square foot. First, the added copper weight enhances the 2 layer 3OZ PCB’s ability to handle higher currents. Thicker copper layers provide lower resistance, thereby reducing the risk of overheating and improving the performance of 2 layer 3OZ pcbs in applications with higher power requirements. Their increased resistance to external factors further enhances their robustness. Thicker copper layers provide better protection against corrosion, ensuring long-term stability and reliability of the circuit.

Advantages of 2-layer design

Although the 2 layer 3OZ PCB has a compact design with only two layers, its durability is not compromised. Enhanced current carrying capacity is the critical advantage. The increased copper weight increases conductivity and lower resistance, allowing the PCB to handle higher currents efficiently. This is particularly advantageous in power electronics applications, where components require robust electrical paths, minimizing the risk of overheating and increasing the system’s overall efficiency. Additionally, the design facilitates better impedance control. The added copper weight allows precise trace width and spacing adjustment, ensuring consistent impedance values across the PCB. This is critical for applications where signal integrity is vital, such as high-speed data transmission or RF circuits.

How does a 2 layer 3OZ PCB excel in thermal management?

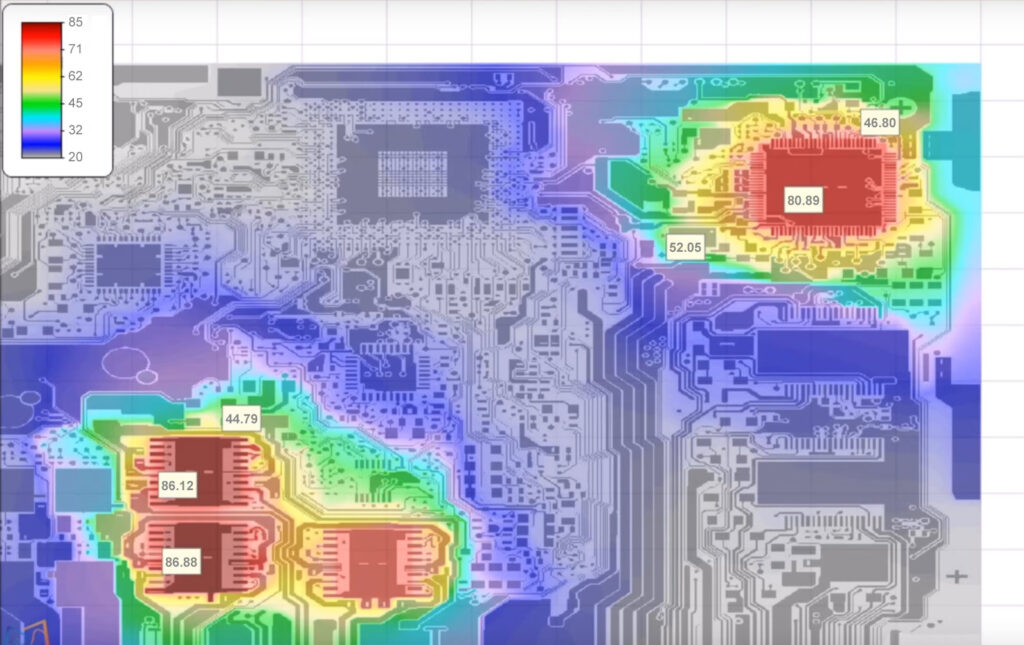

A significant factor in achieving superior thermal management is the increased copper weight on both sides of a 2 layer 3OZ pcb. Thicker copper layers improve thermal conductivity, allowing the board to dissipate heat generated during operation effectively. This is particularly beneficial in applications where components experience high power levels or operate for long periods, preventing overheating and ensuring the longevity of the electronic system. The 2-layer 3oz PCB design facilitates efficient placement of heating components on both sides of the board. This strategic component placement, combined with the enhanced thermal conductivity of the thicker copper layer, results in more even heat distribution throughout the PCB. This reduces localized hot spots and ensures the entire board contributes to efficient heat dissipation.

Balanced flexibility and robustness

The balance of flexibility and robustness of the 2 layer 3OZ pcb makes it an adaptable solution. While not as flexible as some thinner or flexible PCB alternatives, 2-layer 3oz PCBs offer enough flexibility to meet specific design requirements and space constraints. The balance between flexibility and robustness is particularly evident in the PCB’s ability to withstand mechanical stress. The added copper weight on both sides helps improve the board’s overall rigidity, ensuring it can withstand vibration, bending, or other physical stresses without affecting its functionality. Maintaining mechanical strength is crucial in automotive, aerospace, and industrial automation applications, where electronic components can be exposed to challenging environmental conditions.

Certified rugged

A fundamental aspect of the certification process involves mechanical testing. Testing authorities evaluate their structural integrity by subjecting them to tests for flexural strength, bending, and torsional stress. These evaluations ensure the board can withstand physical stress and environmental conditions without affecting its functionality. They are thermally tested to effectively dissipate heat and maintain stability in applications with varying thermal requirements. In addition, the 2-layer 3oz PCBs have also been subjected to vibration and shock testing, passing their resistance to mechanical vibrations and sudden impacts. These tests are essential for applications in industries such as automotive and aerospace.

Final

The ruggedness of 2-layer 3OZ PCBs has become critical in shaping the modern electronics landscape. Their durability, efficient thermal management, flexibility, and rigorous testing make these PCBs a reliable choice for applications requiring consistent and fast performance.