Meets solder mask color and surface finish requirements for 4 layer heavy copper pcb

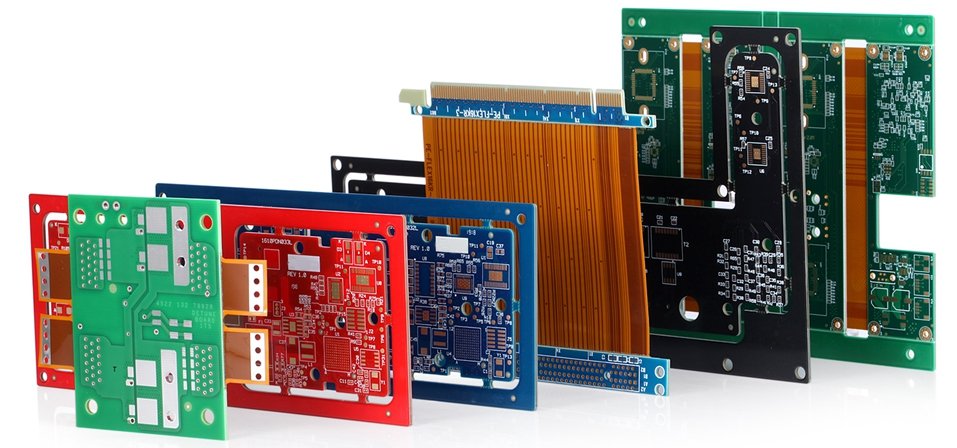

4 layer heavy copper PCB is a specialized type of printed circuit board suitable for handling high-current and high-temperature applications. When many users purchase them in large quantities, in addition to asking about price and size, they also ask whether they can meet the requirements for solder mask color and surface treatment. The article will introduce how MZH Electronics can meet your solder mask color and surface treatment requirements and what technology it will adopt.

4 layer heavy copper PCB The Importance of PCB Solder Mask Color

For 4 layer heavy copper PCB, the choice of solder mask color is very important, affecting the thermal performance of 4-layer thick copper PCB. Darker colors of solder masks (black or dark green) tend to absorb more heat than lighter colors (white or light green). In some applications with high thermal management requirements, choosing a light-colored solder mask can help dissipate heat more effectively, thereby increasing the reliability and service life of the PCB. Secondly, the solder mask color ensures optimal contrast and visibility during assembly and inspection. The contrasting color between the solder mask and the underlying copper traces improves visual clarity and makes it easier for technicians to identify during quality control inspections. Potential defects such as solder bridges or open circuits.

Choose the right solder mask color!

At MZH Electronics, our team evaluates the functional requirements of 4 layer heavy copper PCBs, considering factors such as thermal management, electrical performance, and signal integrity. For applications where heat dissipation is critical, we prioritize lighter solder mask colors, such as white or aqua, to enhance heat dissipation and prevent components from overheating. In addition, we consider customer requirements, including brand preferences and aesthetics. During the cooperation, we will determine your specific color preferences to meet your technical requirements for 4 layer heavy copper PCB design.

The importance of surface treatment

The surface treatment of a 4 layer heavy copper PCB affects the final product’s performance, reliability, and longevity. One of the main purposes of surface treatment is to facilitate solderability during assembly. Proper preparation must be made to accept the solder to establish a reliable electrical connection with component leads or solder paste during assembly. Surface treatments like hot air leveling (HASL), immersion silver, immersion tin, or other surface treatments create a uniform and solderable surface, promoting strong solder joints and minimizing the risk of soldering defects. Additionally, surface treatments protect the copper layer from oxidation and corrosion, which can compromise the integrity of electrical connections over time.

Common surface treatment options

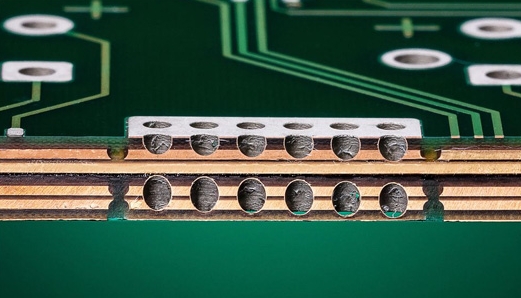

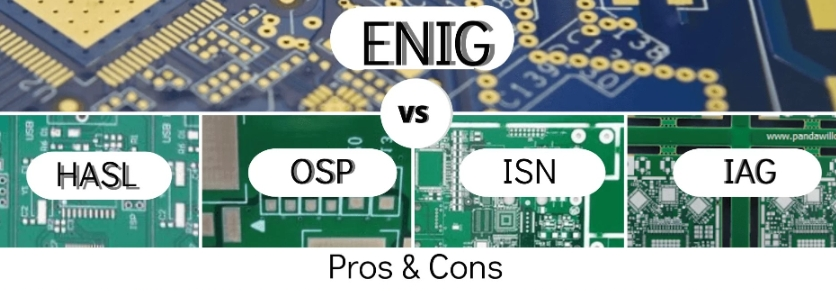

In the world of 4 layer heavy copper pcbs, there are typically various surface treatment options, each with unique features and benefits. Hot air leveling (HASL) is one of the most traditional surface treatment methods for PCBs. It involves applying a layer of molten solder to a copper surface and then using hot air to smooth it out to create a smooth, even surface. This approach is cost-effective and ideal for through-hole components, but may not be suitable for fine-pitch SMT components due to uneven surface topography.

Electroless Nickel Immersion Gold (ENIG) is a popular surface treatment option that provides excellent solderability, corrosion resistance, and flatness. It involves depositing a thin layer of nickel and then depositing a layer of immersion gold on top of the copper. It has low surface roughness and stable electrical properties and is particularly suitable for fine-pitch SMT components and high-frequency applications. Known for its excellent solderability and conductivity, immersion silver involves dipping a PCB into a silver solution to deposit silver onto the copper surface selectively.

Meet surface finish requirements

To meet user surface treatment requirements, various surface treatment options are used tailored to the specific needs of different PCB designs and applications. We typically recommend Electroless Nickel Immersion Gold (ENIG) as our preferred surface treatment option. ENIG provides a uniform, weldable surface with excellent corrosion resistance, making it ideal for high-reliability applications such as aerospace, automotive, and medical equipment. ENIG’s low surface roughness and stable electrical performance are also ideal for fine-pitch components and high-speed digital applications.

If you want more cost-effectiveness, we offer alternatives such as Hot Air Leveling (HASL) or Organic Solderability Preservative (OSP). HASL is suitable for through-hole components and low-cost PCBs. OSP, on the other hand, is an excellent choice for low-volume production due to its environmental friendliness and ease of application.

Meet your solder mask color and surface treatment requirements

The choice of solder mask color affects aesthetics, inspection contrast, and thermal performance. At the same time, surface treatment options such as tinning, ENIG, and OSP provide various benefits for solderability, flatness, and environmental compatibility. We will carefully select the color and surface treatment according to your situation to meet your requirements for a 4 layer heavy copper PCB solder mask.