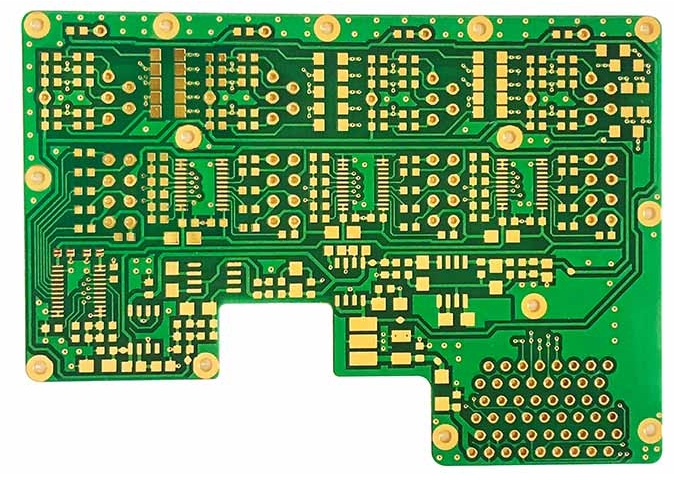

How 4 layer heavy copper PCB Improve Server Efficiency and Power Density?

As demand for applications continues to increase, so does the need for high-performance servers that can handle complex workloads. Therefore, manufacturers of various types of servers are constantly seeking innovative solutions to improve efficiency and power density. One solution is to use a 4 layer heavy copper PCB, which offers numerous advantages in terms of performance, thermal management, and power delivery.

4 layer heavy copper PCB for enhanced thermal conductivity and heat dissipation

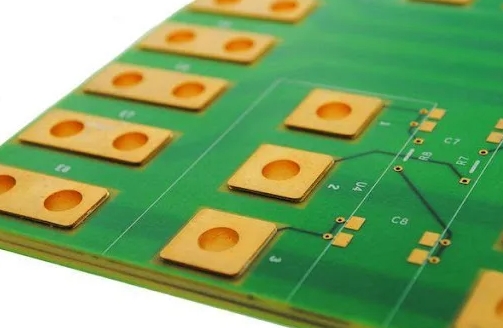

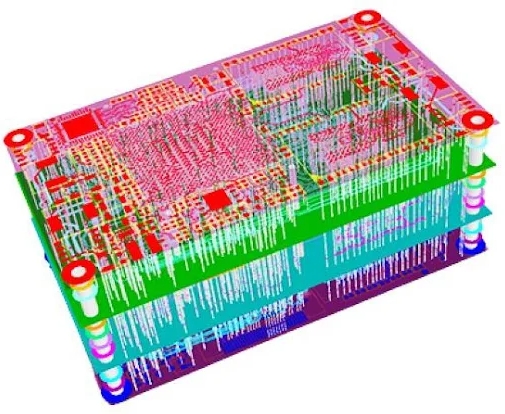

One of the main advantages of 4 layer heavy copper PCBs in server applications is thermal conductivity and heat dissipation capabilities. 4 layer heavy copper PCB act as efficient heat sinks, quickly dissipating heat generated by server components. A key characteristic that differentiates a 4-layer thick copper PCB is the presence of thick copper layers in the PCB stack up. Unlike standard PCBs with thinner copper layers, the increased thickness of the copper layer allows for better heat conduction, allowing heat to be dissipated more efficiently across the PCB surface.

4 layer heavy copper PCBs typically use high thermal conductivity materials for the core and prepreg layers. These materials have better heat transfer properties than traditional FR-4 materials. Using highly thermally conductive materials helps quickly move heat away from heating components. Thermal vias play a vital role in promoting PCB heat dissipation by providing a channel for heat to travel from components to the outer layer of the PCB. Thermal vias are strategically placed in the 4-layer thick copper PCB to increase thermal conductivity and ensure efficient heat dissipation.

4 layer heavy copper PCB optimizes power delivery and distribution

Another benefit of 4 layer heavy copper PCBs is optimizing power transmission and distribution within server systems. The 4-layer thickness reduces resistance and impedance, allowing for more efficient power transfer from the server’s power supply unit to individual components. Improved voltage regulation, reduced power losses, and enhanced overall system stability ultimately help improve server efficiency and performance. The thick copper layers in the 4-layer PCB provide excellent thermal conductivity, helping to dissipate heat efficiently from power-intensive components. Efficient cooling helps prevent thermal throttling and ensures server systems maintain consistent performance under heavy workloads.

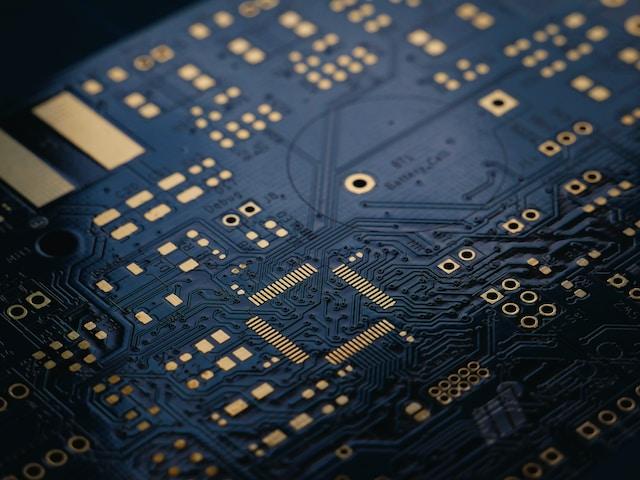

Reduce signal loss and crosstalk in server applications

In addition to power delivery and distribution, 4 layer heavy copper PCBs reduce signal loss and crosstalk in server applications. 4 layer heavy copper PCB provides better impedance control and signal integrity, reducing the risk of data transmission errors and signal interference between different circuit traces. This ensures reliable communication between components and peripherals. The 4 layer heavy copper PCB is designed with controlled impedance traces to ensure consistent signal propagation characteristics across the PCB substrate. These PCBs minimize impedance changes by precisely controlling trace width, thickness, and dielectric properties, thereby reducing signal reflections and losses that can degrade signal quality.

Enables more compact designs and higher power density

Using 4 layer heavy copper PCBs enables server manufacturers to achieve more compact, space-saving designs without compromising performance or reliability. Thick copper layers increase power density, allowing for more powerful components and higher-capacity memory modules to be integrated within the same physical footprint. This results in denser server configurations, with 4 layer heavy copper PCBs having significantly thicker copper layers and, therefore, higher current carrying capabilities and lower resistance than standard PCBs. Increased copper trace thickness reduces voltage drop and power loss, allowing efficient power delivery to critical server components without impacting performance.

Improve server application reliability and longevity

With its rugged construction and enhanced thermal management capabilities, 4 layer heavy copper PCB offers greater reliability and longer life than traditional PCB designs. One of the major factors affecting server application reliability is thermal management. The 4 layer heavy copper PCB has high thermal conductivity for efficiently cooling power-dense components such as CPUs, GPUs, and power supply circuits. By efficiently dissipating heat, these PCBs reduce the risk of failure caused by thermal stress. Thick copper traces in 4-layer PCBs have lower resistance and impedance, reducing voltage drops and power losses during operation. This optimized power delivery reduces the risk of voltage fluctuations and ensures stable power distribution to critical server components, thereby increasing overall system reliability.

Harness the power of 4 layer heavy copper PCB

4 layer heavy copper PCBs increase server efficiency and power density in modern data center environments. They provide server application manufacturers with a series of advantages due to their thermal conductivity, optimized power transmission, minimized signal loss, and compact design. , so it is one of the best options for server manufacturers.