Carbon Ink PCB: A Cost-Effective Solution for High-Performance Circuits

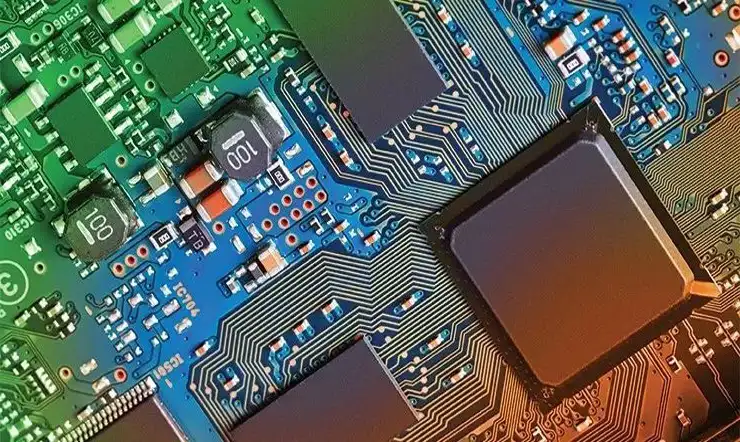

The world of electronics is rapidly evolving, demanding solutions that are both high-performing and cost-effective. Carbon Ink PCB is a standout innovation that meets these needs. This unique printed circuit board (PCB) technology has gained popularity across various industries, offering a cost-effective solution without sacrificing performance. Manufacturers achieve reliable circuits at a lower cost by using conductive carbon ink for circuit design. Carbon Ink PCBs are reshaping how circuits are manufactured from consumer electronics to automotive systems.

Affordable Performance with the Power of Carbon Ink PCB

Producing high-performance circuits traditionally involved significant investments in materials and manufacturing. Carbon Ink PCBs change this by offering an affordable alternative. Instead of copper-based PCBs, Carbon Ink PCBs use carbon-based ink for conductive pathways, reducing raw material costs while maintaining circuit reliability. The simplified production process also contributes to lower overall costs, making Carbon Ink PCBs a more budget-friendly option. This makes it a popular solution for industries prioritising cost savings and high performance, like automotive and consumer electronics.

Durability and Reliability in Harsh Environments

Carbon Ink PCB is known for its durability and reliability in harsh environments, making it ideal for demanding applications. Unlike traditional PCBs vulnerable to temperature changes and moisture, Carbon Ink PCB resists these conditions. This robust nature ensures circuits stay functional even in extreme environments, such as industrial machinery and automotive components. As a result, Carbon Ink PCBs help extend the lifespan of devices. It reduces the likelihood of failures, making it a wise choice for industries requiring long-lasting and dependable circuits.

Environmental Benefits of Carbon Ink PCB

Carbon Ink PCBs also offer significant environmental benefits. As industries push for more sustainable solutions, Carbon Ink PCB meets this demand by requiring fewer raw materials and being more energy-efficient to produce. Unlike traditional PCB production, which often uses hazardous chemicals and metals like copper, Carbon Ink PCBs reduce environmental impact. Additionally, it is more easily recyclable, making it a more eco-friendly option. For companies seeking to lower their carbon footprint, Carbon Ink PCB offers a responsible choice for reducing environmental impact.

Efficiency in High-Volume Production

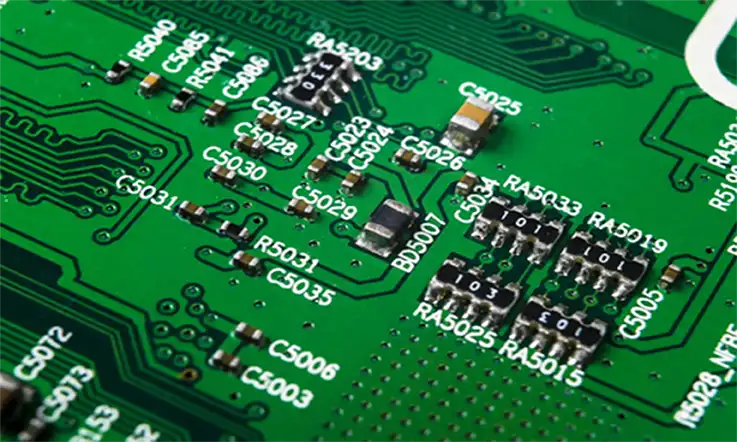

One of the key advantages of Carbon Ink PCBs is their efficiency in high-volume production. Carbon ink enables faster production and lower costs compared to traditional copper-based methods. The traditional PCB manufacturing process involves time-consuming steps like etching copper traces, which add complexity and cost. Carbon Ink PCBs simplify the process, reducing production time and labour. As a result, manufacturers can produce large quantities of PCBs quickly and affordably. This efficiency is particularly valuable in industries like consumer electronics, where high-volume production is essential to meet growing demand.

Improved Design Flexibility

Carbon Ink PCBs offer exceptional design flexibility that traditional methods cannot match. Printing circuits with carbon ink allows for more intricate designs, which are crucial for advanced applications. In wearable technology, for example, circuits must be compact and flexible. Carbon Ink PCB enables the creation of lightweight and flexible circuits that fit these design requirements. Its ability to be printed on various substrates allows for greater freedom in circuit layouts, encouraging innovation and opening new possibilities in product design.

Scalability for Emerging Technologies

As emerging technologies like IoT, 5G, and smart cities expand, the demand for scalable, high-performance circuits grows. Carbon Ink PCB is a scalable solution that meets the needs of these next-generation technologies. It can be produced in large quantities at a low cost, making it perfect for IoT devices, connected infrastructure, and other emerging applications. Its scalability also benefits startups and smaller companies, enabling them to compete with larger players. This affordability and flexibility drive innovation and ensure the growth of new industries.

The Future of High-Performance Circuits with Carbon Ink PCB

Carbon Ink PCB is a cost-effective, durable, and sustainable solution for high-performance circuits. Its affordability, reliability, and flexibility make it ideal for automotive, consumer electronics, and industrial applications. With its environmental benefits and scalability, Carbon Ink PCBs is positioned to play a significant role in the future of electronics manufacturing. For companies seeking cost savings, improved product performance, and sustainability, Carbon Ink PCBs offers a wise, future-proof choice. As industries adopt this technology, its impact on the electronics market will only grow.