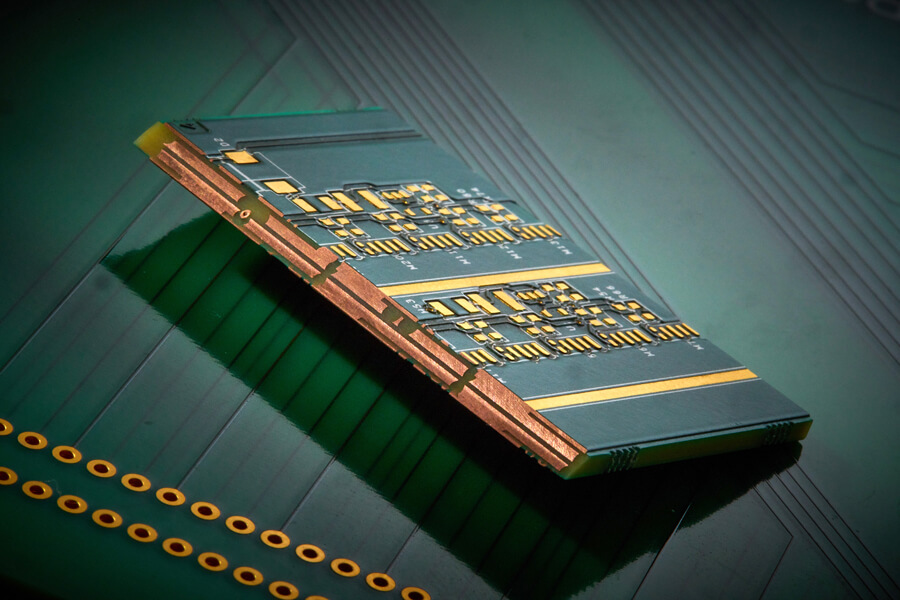

thick copper PCB for Advanced Thermal Management

thick copper PCB technology addresses one of the defining challenges in modern power electronics, where thermal control and performance gains go hand in hand. From electric vehicle charging stations to industrial motor drives and renewable energy inverters, higher power levels must now be delivered within increasingly compact designs. Thick copper PCBs play a critical role in meeting this demand by converting excess heat into a controllable, manageable factor rather than a limiting one. Through optimized copper thickness and intelligent layout, these boards move heat away from sensitive components while supporting heavy current flow with exceptional stability. As a result, thick copper PCBs for advanced thermal management have become a key building block in the development of next-generation high-power electronic systems.

thick copper PCB as the Core of Advanced Thermal Management

Every high-power electronic system lives or dies by how well it manages heat. A thick copper PCB uses heavier copper layers to create wide, low-resistance current paths that naturally conduct heat away from sensitive components. This makes it the foundation of any High Reliability Power PCB design. Unlike standard boards, thick copper structures spread heat across a much larger surface area. That allows power devices, MOSFETs, and drivers to operate at lower temperatures, even under heavy electrical load. In advanced thermal management systems, this translates into longer component life, higher power density, and fewer thermal failures. When customers choose a they are not just selecting a circuit board—they are choosing a thermal control platform designed for real-world power conditions.

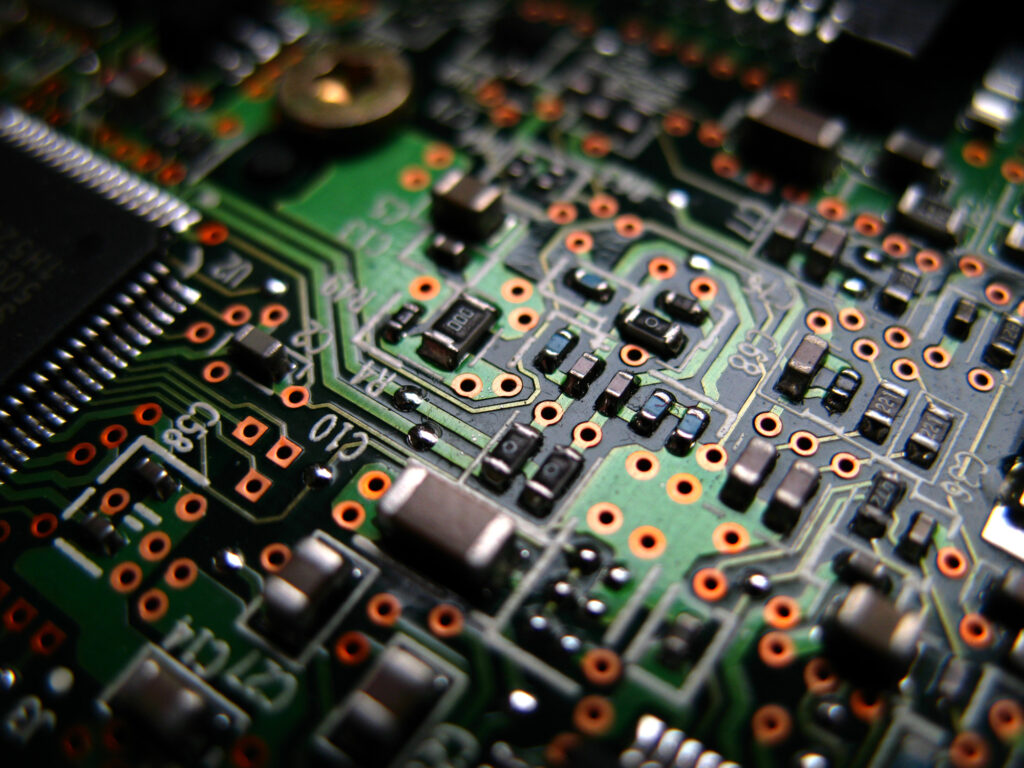

Optimizing Heat Flow in High-Reliability Power Circuit Board Designs

Effective thermal management is all about controlling heat flow. A excels here because its copper planes serve as both electrical conductors and thermal highways. In High Reliability Power PCBs applications, this dual role improves both efficiency and safety. By reducing electrical resistance, a thick-copper layout lowers Joule heating at the source. At the same time, it pulls heat away from hot spots and distributes it evenly across the board. This reduces thermal gradients that cause solder fatigue, material stress, and early failure. In advanced thermal systems, this stable temperature profile makes designs far more reliable than conventional alternatives.

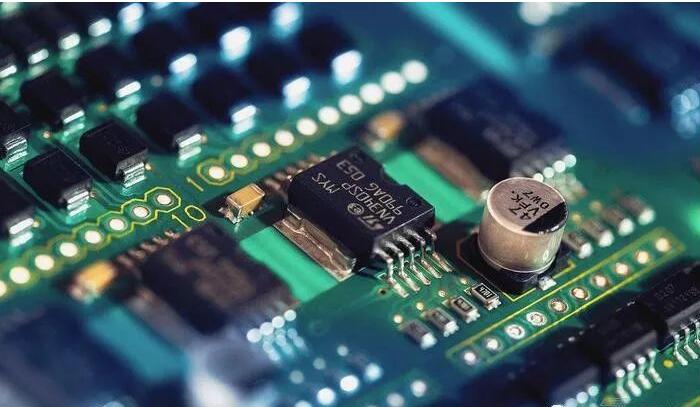

thick copper PCB in High-Power and High-Temperature Environments

Power electronics often operate in extreme conditions, from industrial automation floors to outdoor energy systems. A is engineered for environments like these. The thick copper layers provide mechanical strength and thermal stability, which are essential for any High Reliability Power PCB. In high-current applications, thin copper traces can overheat, deform, or crack. Thick copper, however, handles large current loads without excessive temperature rise. This allows systems to run continuously without thermal shutdowns or performance drops. For advanced thermal management, thick-copper PCB technology ensures heat never becomes the weak link in the system.

Efficient Thermal Solutions for Compact High-Power Systems

As devices become smaller, power density increases. This makes advanced thermal management more critical than ever. A supports compact designs by carrying more current and dissipating more heat in less space, a key advantage for High Reliability Power PCB layouts. Designers can reduce board size, simplify heat-sink requirements, and still maintain safe operating temperatures. This creates more flexible product designs, lower system costs, and better long-term reliability. With thick copper PCB solutions, advanced thermal performance no longer requires bulky cooling structures.

thick copper PCB and Long-Term Thermal Stability

Thermal cycling is one of the biggest causes of PCB failure. Repeated heating and cooling creates expansion stress that weakens solder joints and copper traces. A thick copper PCB resists this damage thanks to its stronger copper structure and better heat distribution, making it ideal for High Reliability Power PCB applications. By keeping temperatures more stable, thick copper designs slow down material fatigue and improve lifetime performance. In advanced thermal management systems, this stability means fewer maintenance cycles, lower failure rates, and higher overall system uptime.

Thick Copper PCB Manufacturing for Advanced Thermal Management

At a thick copper PCB, manufacturing quality is just as important as design. Our production processes control copper thickness, bonding strength, and layer alignment to ensure that every High Reliability Power PCB meets strict thermal and electrical standards. Advanced etching and plating techniques allow us to build complex, thick copper geometries without compromising precision. This means customers receive boards that perform exactly as designed, even in high-temperature and high-current environments. For advanced thermal management, consistent manufacturing quality is what turns engineering theory into real-world performance.

Why thick copper PCB Leads Advanced Thermal Management

The future of power electronics demands boards that can move heat as effectively as they move electricity. A delivers both, making it the ideal platform for advanced thermal management and high-reliability power PCB design. By combining superior heat dissipation, high current capacity, and mechanical strength, thick copper solutions allow engineers to push performance further without sacrificing safety or lifespan. At thick copper PCB, we build every board with this balance in mind, ensuring our customers receive solutions that perform today and remain reliable for years to come.