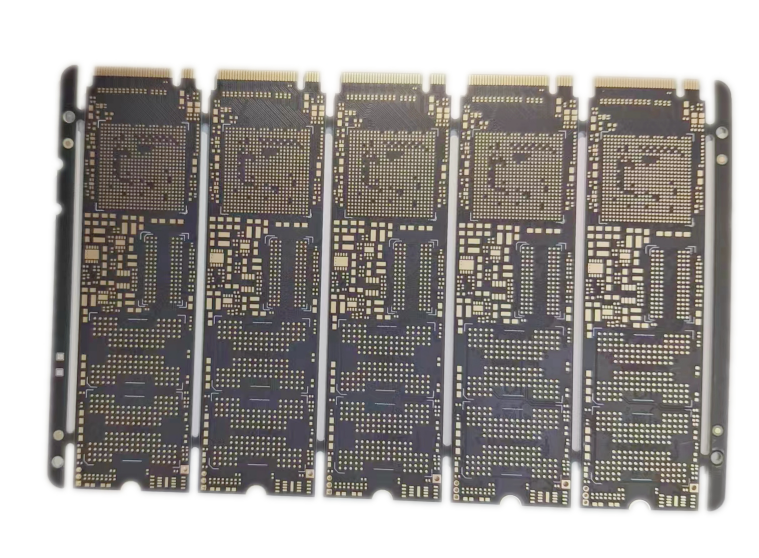

SSD PCB Manufacturing Standards for Storage Applications

SSD PCB solutions are printed circuit boards designed specifically for solid-state storage. Their performance requirements extend beyond speed to include stability, durability, and signal integrity, and they are widely used in consumer electronics, enterprise storage, and high-performance computing.

Solid-state drive PCB manufacturing focuses on long-term storage reliability, with its design, development, and production adhering to stringent standards. The selection of materials and process control in Solid-state drive PCB manufacturing directly affects performance during continuous operation, ensuring reliable, stable results even in demanding storage environments.

SSD PCB Material Selection and Structural Standards

Material quality defines the baseline performance of any Solid-state storage PCB. Most designs use FR4 or high-frequency laminate materials, selected for their balance of electrical stability, mechanical strength, and cost efficiency. These dielectric materials support high-speed data transmission while maintaining consistent performance over extended operating cycles.

Copper thickness also plays a critical role. Standard Solid-state drive PCB designs typically range from 1 oz to 3 oz copper, allowing engineers to balance current capacity, heat dissipation, and board durability. Thicker copper improves power delivery and thermal performance, especially in enterprise and industrial storage environments.

SSD controller board Trace Design and Signal Integrity Control

High-speed data transfer depends on precise trace design. In a Solid-state storage PCB, narrow traces handle high-speed signal routing, while wider traces support stable power transmission. This separation helps reduce interference and ensures clean signal paths between controllers, flash memory, and connectors.

Equally important is impedance control. Differential signal pairs must maintain tightly controlled impedance to prevent reflection, loss, or timing errors. By following strict Solid-state storage PCB manufacturing standards, designers ensure accurate data transmission even under demanding workloads.

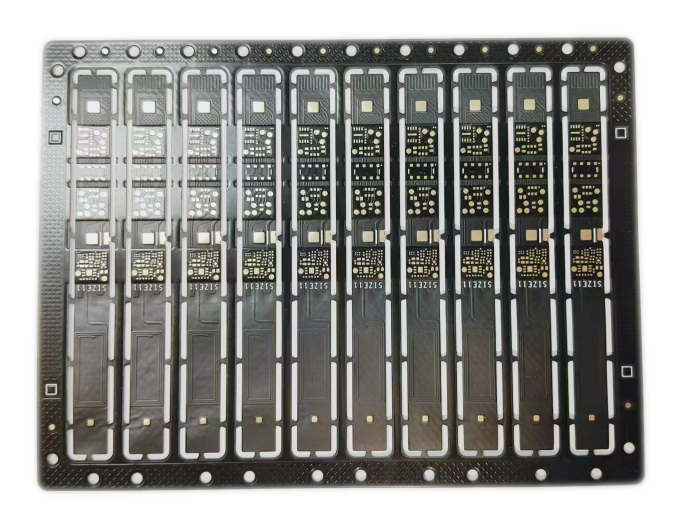

SSD PCB Via Quality and Electrical Reliability

Interlayer connections serve as the board’s internal pathways, linking multiple layers and enabling compact, high-density layouts. The dimensions, positioning, and plating quality of these connections directly influence signal stability and long-term electrical performance.

Robust copper deposition within these structures enhances conductivity and mechanical strength, lowering the risk of failure during thermal cycling. In continuously running storage systems, such design standards help maintain consistent electrical behavior throughout the product’s service life.

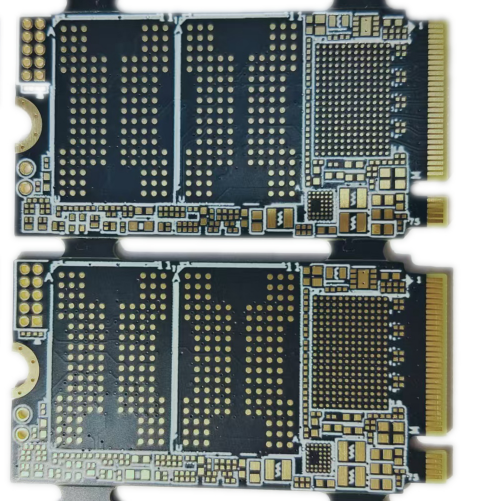

SSD Controller Board Thermal Management and Heat Dissipation

As storage densities increase, heat management becomes essential. A well-designed SSD PCB often incorporates thermal vias, heat-dissipation holes, and deep or embedded copper layers to spread heat away from controllers and memory chips.

Effective thermal design not only protects components but also stabilizes performance. By controlling operating temperatures, Solid-state drive PCB manufacturing standards help prevent throttling and extend the lifespan of critical storage components.

SSD PCB Surface Finish and Assembly Compatibility

Surface finish selection affects both assembly quality and long-term reliability. Standard SSD controller board finishes include ENIG, HASL, and OSP, each offering specific advantages depending on application requirements.

ENIG provides excellent flatness and corrosion resistance, making it ideal for fine-pitch components. HASL offers robust solderability, while OSP supports cost-effective production. Choosing the right finish ensures strong solder joints and consistent manufacturing results.

SSD Controller Board Testing Standards and Application Versatility

Every SSD controller board undergoes rigorous electrical testing to verify signal paths, power distribution, and functional integrity before deployment. These tests confirm that the board meets strict performance and reliability standards required for storage applications.

As a result, Solid-state drive PCB solutions support a wide range of industries, including consumer electronics, automotive electronics, medical devices, aerospace and defense, and telecommunications. This versatility highlights the importance of consistent manufacturing standards across all storage-focused designs.