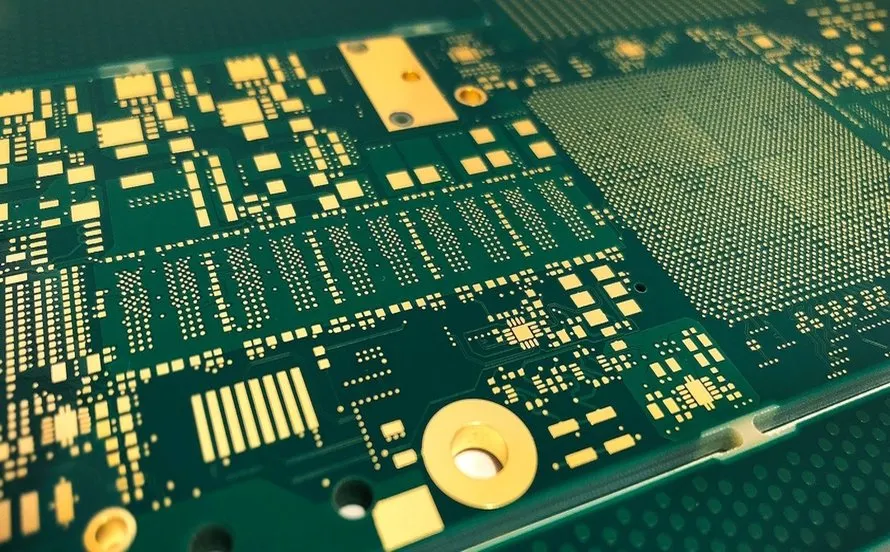

Multilayer Ceramic PCB Reliability in Extreme Conditions

Multilayer Ceramic PCB technology offers inherent thermal stability and low material expansion, unlike organic PCB materials. In a multilayer ceramic PCB, this stability extends across internal layers, ensuring consistent electrical pathways and predictable performance. For customers evaluating installation systems or long-term deployment, multilayer ceramic PCBs‘ reliability in extreme conditions is often the decisive factor, and these solutions are specifically engineered to address that need.

Multilayer Ceramic PCB Performance Under High-Temperature Stress

High-temperature exposure is one of the most critical challenges in extreme environments. Multilayer ceramic PCB structures excel in this area due to their ability to withstand sustained heat without mechanical deformation or electrical drift. Ceramic materials maintain their dielectric properties and insulation strength even when temperatures fluctuate rapidly or remain elevated for extended periods. In Multilayer Ceramic Circuit Board designs, internal conductor layers remain stable because ceramic substrates exhibit low thermal expansion and excellent heat resistance. This prevents warping, delamination, or micro-cracking that can compromise signal integrity. For systems such as RF and microwave modules, where thermal stability directly affects frequency performance, this advantage is essential.

Multilayer Ceramic PCB Resistance to Mechanical Stress and Vibration

Mechanical stress, shock, and vibration are common in aerospace, defense, and industrial applications. Multilayer Ceramic Circuit Board assemblies offer superior structural rigidity, enabling them to resist deformation and maintain precise layer alignment under continuous mechanical loading. This rigidity protects both conductive traces and mounted components from fatigue-related failures. In a Multilayer Ceramic Circuit Board, the ceramic substrate serves as a stable foundation, minimizing layer-to-layer movement. This reduces the risk of cracked solder joints, trace separation, or intermittent electrical connections. Multilayer Ceramic Circuit Board designs are therefore well-suited for equipment exposed to vibration, acceleration, or repeated mechanical impact, where long-term reliability is non-negotiable.

Multilayer Ceramic PCB Stability for RF and Microwave Systems

RF and microwave systems are particularly sensitive to material instability. Even slight changes in dielectric constant or conductor spacing can affect signal transmission and system accuracy. Multilayer ceramic PCB technology offers exceptional electrical stability, ensuring consistent impedance and minimal signal loss across a wide range of operating conditions.

Ceramic materials provide low dielectric loss and stable electrical characteristics, which are critical for high-frequency applications. In Multilayer Ceramic Circuit Board constructions, this stability is maintained across all layers, enabling compact, high-density designs without compromising performance. Multilayer Ceramic Circuit Board solutions are widely used in communication systems that require precision and reliability in extreme environments.

Reliability of Ceramic Circuit Boards in Aerospace and Defense Applications

Aerospace and defense systems operate in some of the harshest conditions imaginable, including extreme temperatures, pressure changes, and constant vibration. Multilayer ceramic PCB reliability makes these substrates a preferred choice in applications where failure is simply not acceptable. From avionics to radar systems, ceramic-based boards deliver consistent performance over long service lifetimes. Multilayer Ceramic Circuit Board designs ensure that critical electronic functions remain stable during takeoff, flight, and landing, as well as in space or on the battlefield. Their resistance to thermal shock and mechanical fatigue supports mission-critical reliability. For organizations prioritizing system safety and performance, Multilayer Ceramic Circuit Board technology provides a proven foundation.

Advantages of Ceramic Circuit Boards Compared to Conventional PCB Materials

Compared with traditional FR4 or metal-core PCBs, multilayer ceramic PCBs offer a clear reliability advantage in extreme environments. Organic materials can absorb moisture, degrade under heat, or undergo material expansion, which can affect electrical performance. Ceramic substrates, by contrast, remain dimensionally stable and electrically consistent. This stability reduces long-term maintenance requirements and minimizes the risk of unexpected system failures. Multilayer ceramic PCB designs also support higher power densities and tighter tolerances, enabling compact systems without sacrificing reliability. These advantages make Multilayer Ceramic Circuit Board solutions especially attractive for high-value, high-risk applications.

Reliability of Ceramic Circuit Boards as a Long-Term Investment

Selecting a multilayer ceramic PCB is not only a technical decision but a strategic one. Reliability in extreme conditions directly impacts system uptime, maintenance costs, and overall lifecycle performance. By investing in multilayer ceramic PCB technology, customers gain long-term stability that reduces operational risk and supports consistent system performance. From an engineering standpoint, multilayer ceramic PCB solutions are designed to deliver predictable results even under increasing environmental stresses. Their proven reliability across demanding industries continues to drive adoption in applications where durability, precision, and performance must coexist. Multilayer Ceramic Circuit Board technology remains a cornerstone for electronics designed to endure.