How to Reduce Defects in Set-top Box SMT Assembly Lines?

Set-top Box SMT assembly lines often face defects that reduce yields and increase costs. To maintain quality, identify root causes, and optimise processes. Start with PCB inspection, solder paste control, and component placement. Meanwhile, monitor reflow profiles and operator handling. Proper training and consistent procedures help prevent mistakes and also facilitate the recording of data for continuous improvement. With proactive steps, defects drop, and throughput rises, ensuring reliable Set-top Box SMT production.

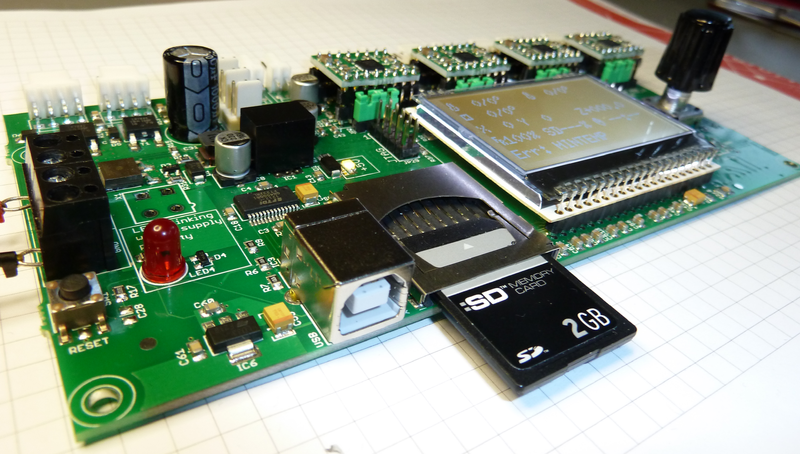

Standardise Material Handling

Proper handling of components and set-top PCB boards prevents contamination and damage: store PCBs and components in a controlled environment with stable humidity and temperature. Ensure operators use ESD protection and clean tools at all times. Additionally, label all materials clearly to avoid mix-ups. Regularly audit supply quality and inventory management to ensure optimal efficiency and effectiveness. Consequently, consistent material handling reduces soldering issues and component failures. Standardisation improves line stability and lowers overall defect rates in Set-top Box SMT.

Optimise Solder Paste Application

Solder paste defects are common in Set-top Box SMT assembly. Use automated printers with correct stencil thickness and aperture design. Monitor paste viscosity and temperature constantly. Perform test prints regularly to ensure deposition accuracy. Moreover, train operators should be trained to quickly identify anomalies. Utilise inspection tools such as SPI (Solder Paste Inspection) for real-time feedback. Thus, optimising solder paste application minimises bridging, tombstoning, and opens. Ultimately, paste control directly impacts yield in Set-top Box SMT.

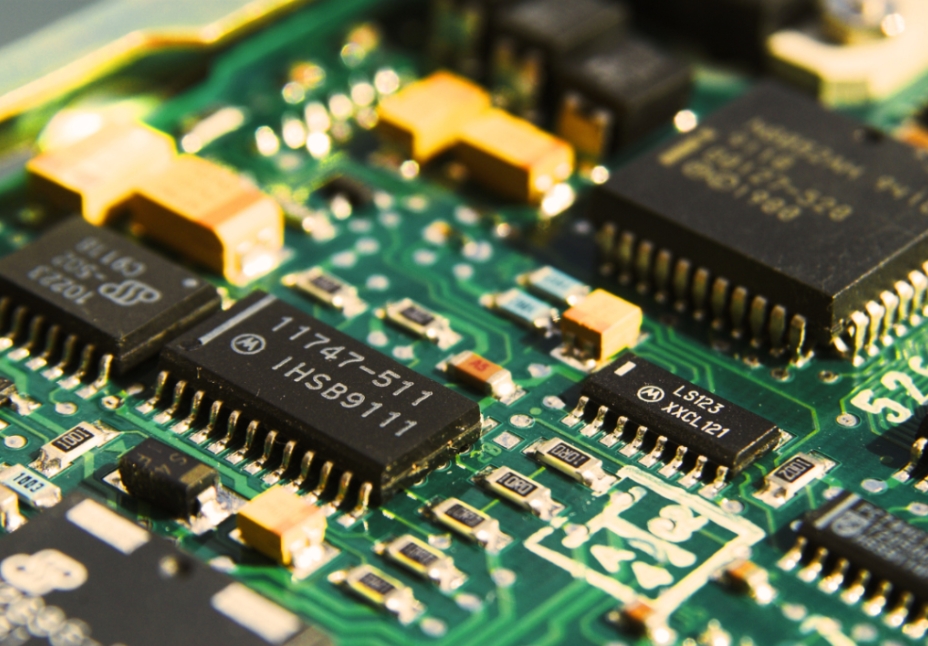

Improve Component Placement Accuracy

Accurate placement prevents rework and reduces defects in SMT Set-top Boxes. Utilise high-precision pick-and-place machines for precise and consistent alignment. Check feeders and nozzle calibration frequently. Additionally, review CAD and assembly data for placement tolerances. Operators should verify high-value or fine-pitch components manually to ensure accuracy. Real-time monitoring helps catch placement errors early. Therefore, accurate placement ensures solder joints form correctly on the set-top PCB, boosting reliability and throughput.

Reflow Profile Control

Reflow temperature profiles are crucial to the quality of solder joints. Measure PCB temperature with thermocouples at key points. Adjust conveyor speed, zone temperatures, and ramp rates accordingly. Avoid overheating that damages components or underheating that causes weak joints. Conduct regular thermal audits and log results for continuous improvement. By precisely controlling the reflow process, defects such as voids, cracks, or insufficient wetting are minimised. Proper thermal management safeguards both the set-top PCB and its components.

Regular Inspection and Testing

Inspection catches defects before products ship. Utilise automated optical inspection (AOI) to detect soldering and component placement errors. Implement X-ray inspection for BGAs or hidden joints. Additionally, functional testing validates electrical performance. Record inspection outcomes to identify recurring issues. Train operators to respond promptly to deviations. Consequently, ongoing inspections reduce waste, improve first-pass yield, and ensure high-quality Set-top Box SMT output.

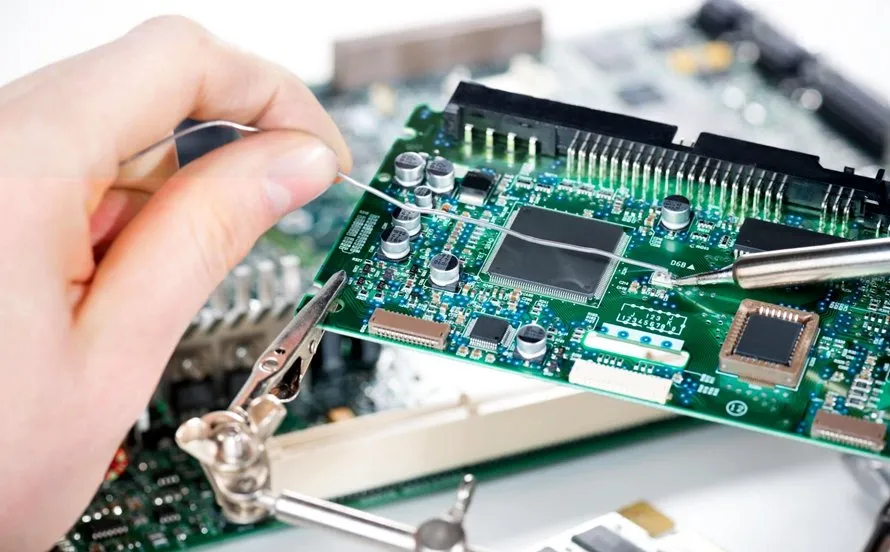

Operator Training and Best Practices

Operators are key to preventing defects. Provide structured training on handling the set-top PCB, soldering techniques, and equipment operation. Encourage adherence to standard operating procedures (SOPs). Conduct refresher courses and share lessons from past defects. Promote a culture of accountability and quality awareness. By empowering staff, human errors drop significantly. In the long term, trained operators stabilise line performance and reduce rework in Set-top Box SMT.

Continuous Data Monitoring

Real-time data collection supports rapid corrective action. Monitor solder paste volume, placement accuracy, reflow temperatures, and inspection results to ensure optimal performance. Use statistical process control (SPC) charts to track trends. Detect deviations quickly to prevent full-batch defects. Regularly review metrics to identify process improvements. Consequently, continuous monitoring drives proactive quality management. This approach ensures Set-top Box SMT lines maintain high yield and consistent product performance.

Best Practices to Reduce Defects in Set-top Box SMT

Reducing defects in Set-top Box SMT requires effective material control, optimised solder paste, accurate placement, effective thermal management, thorough inspection, comprehensive operator training, and continuous data monitoring. Combining these strategies improves yield, reliability, and throughput. By maintaining rigorous standards and continuously reviewing their processes, manufacturers minimise rework, protect the set-top PCB, and consistently produce high-quality, dependable devices. Implementing these best practices strengthens both production efficiency and customer satisfaction.