How Metal Substrate PCB is Paving the Way for Smarter Electronics

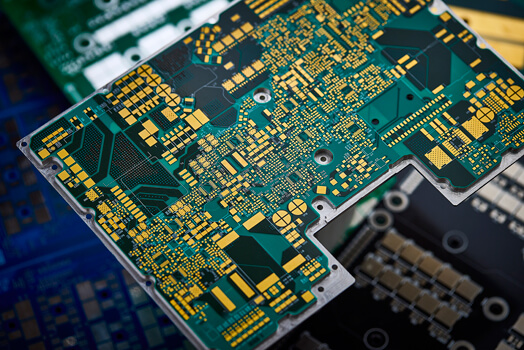

Driven by advancements in technology and the increasing demand for higher performance, efficiency, and miniaturization. At the heart of these innovations lies the Metal Substrate PCB, a key enabler for smarter, more reliable electronics. This specialized PCB technology is revolutionizing the way devices handle heat, electrical performance, and overall reliability.

Heat Management in Modern Electronics with Metal Substrate PC

Managing heat dissipation has become increasingly crucial. Devices are getting smaller and more powerful, generating more heat that can damage internal components. Metal Substrate PCB technology stands out because of its excellent thermal conductivity. Unlike traditional FR4 PCBs, which are made from glass-reinforced epoxy, Metal Substrate PCBs feature a metal base (typically aluminum or copper) that acts as a heat sink, dissipating heat away from sensitive components. This efficient heat management helps to prevent overheating, enhancing the lifespan and performance of electronic devices.

With this superior heat dissipation, Metal Substrate PCBs are especially ideal for high-power applications such as LED lighting, power supplies, and automotive systems. The thermal performance of Metal Substrate PCBs not only protects components but also enables devices to operate at optimal levels for more extended periods, making them an indispensable solution for modern electronics.

Enhanced Mechanical Strength for Rugged Applications

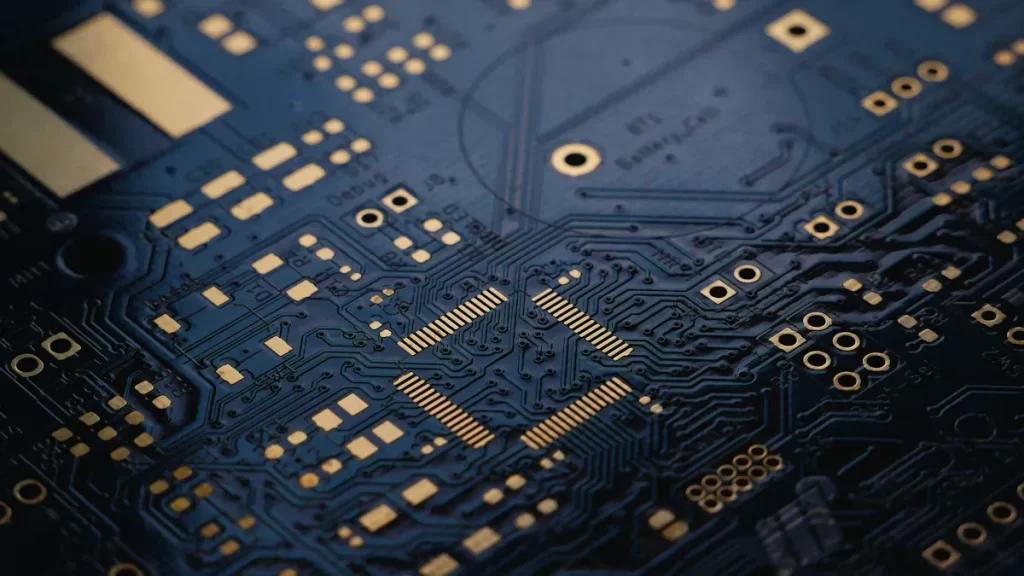

The mechanical strength of a Metal Substrate PCB is another factor that sets it apart from traditional PCBs. Compared to FR4 PCBs, Metal Substrate PCBs offer superior durability and resistance to mechanical stress. This strength makes them well-suited for applications where the PCB may be subject to vibrations, shocks, or extreme environmental conditions. For instance, Metal Substrate PCBs are commonly used in automotive, aerospace, and industrial applications where reliability and durability are paramount.

The high mechanical strength also means that Metal Substrate PCBs are less prone to warping and damage over time. This improves the devices’ overall reliability, making them ideal for mission-critical applications where failure is not an option.

Improved Electrical Performance and Reliability with Metal Substrate PCB

The reliability of electronic components depends not only on their physical structure but also on their ability to manage thermal expansion and electrical performance. Metal Substrate PCBs excel in both of these areas. The metal base layer significantly reduces thermal expansion, a common issue with traditional FR4 PCBs. By mitigating thermal stress, Metal Substrate PCBs improve the device’s overall reliability, ensuring it performs well over time without failure.

Metal Substrate PCBs deliver excellent electrical performance by enhancing signal integrity and reducing electrical noise. The metal core helps maintain consistent impedance and minimize signal distortion, which is critical in high-speed or high-frequency circuits. This enhanced electrical performance is one of the key reasons Metal Substrate PCBs are preferred in industries such as telecommunications, power electronics, and consumer electronics.

The Economic Advantage of Metal Substrate PCB

While Metal Substrate PCBs are often viewed as a higher-end solution, they offer significant long-term economic advantages. The superior thermal management capabilities of Metal Substrate PCBs reduce the need for additional cooling solutions, such as heat sinks or fans. This can help manufacturers save on overall costs, especially in compact devices where space is at a premium. Additionally, the enhanced mechanical strength means that Metal Substrate PCBs are less likely to require replacement, reducing maintenance costs over time. Manufacturers also benefit from the ability to use Metal Substrate PCBs in high-efficiency applications, resulting in lower energy consumption and increased device longevity. All of these factors contribute to a cost-effective solution that is perfect for high-performance electronics across various industries.

Versatility in Applications Across Industries

The versatility of Metal Substrate PCBs spans multiple industries, underscoring their importance in developing more innovative electronics. From automotive systems to consumer electronics, Metal Substrate PCBs are a critical component in the design of power supplies, lighting systems, industrial machinery, and electronic control units. Their high thermal conductivity and mechanical strength make them ideal for these demanding applications, where heat management and reliability are non-negotiable.

In LED lighting, for instance, Metal Substrate PCBs are used to manage the heat generated by high-power LEDs, ensuring optimal performance and a longer lifespan. Similarly, in power electronics, they provide efficient heat transfer in power converters and inverters, reducing the risk of overheating and improving overall system stability.

Future Trends in Metal Substrate PCB Technology

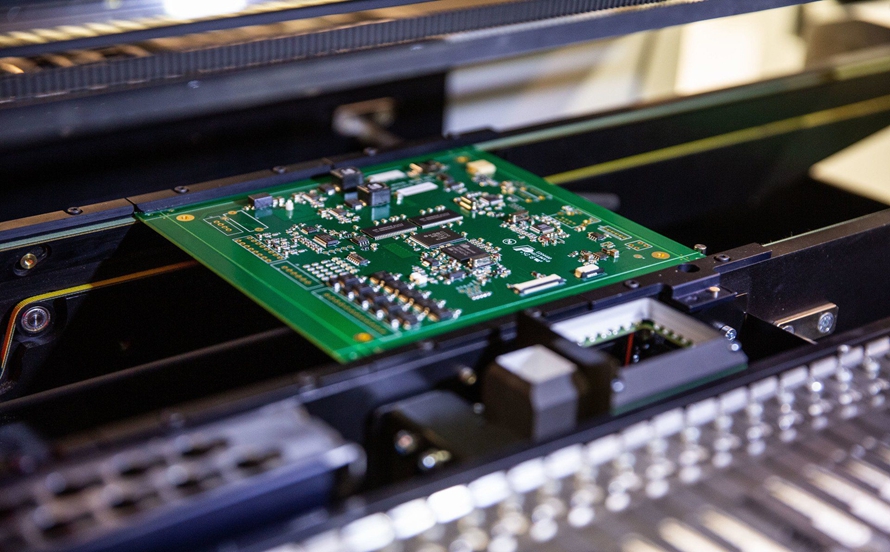

As electronics continue to evolve, so does the demand for Metal Substrate PCBs. In the future, we can expect Metal Substrate PCB technology to play an even more critical role in the design of next-generation electronics. With the rise of electric vehicles, smart cities, and renewable energy systems, the demand for high-performance, heat-resistant PCBs will only increase. Advancements in manufacturing techniques, such as automated assembly and precision laser cutting, will enable Metal Substrate PCBs to become even more efficient and cost-effective. The continued miniaturization of electronic components will also drive the demand for Metal Substrate PCBs that can handle higher power densities without compromising on thermal performance or mechanical integrity.

The Future of Smarter Electronics

Metal Substrate PCBs are not just paving the way for more innovative electronics—they are transforming the landscape of electronic design. With their superior heat dissipation, mechanical strength, and enhanced electrical performance, these PCBs are an essential component for high-performance devices. From consumer electronics to industrial power systems, Metal Substrate PCBs are driving innovation by enabling more innovative, more reliable, and cost-effective solutions.

As technology continues to evolve and demand for high-performance, compact, and efficient electronics grows, Metal Substrate PCBs will remain at the forefront of these advancements, offering solutions that enhance both performance and longevity. For manufacturers looking to stay ahead of the curve, investing in Metal Substrate PCBs is a strategic move that will pay dividends in the long term.