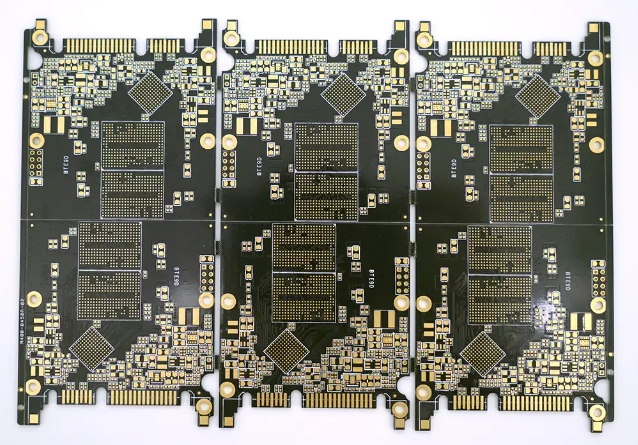

Guarantee the thermal stability and reliability of 6 layer SSD pcb

When using 6-layer SSD PCBs, it is very important to ensure their thermal stability and reliability. This is also a question that many of our customers will ask us at the beginning of our cooperation: how to ensure the thermal stability of 6-layer SSD PCBs. And reliability. This article will explain how we ensure the thermal stability and reliability of 6 layer SSD PCB and the strategies we will adopt.

Thermal Challenges with 6 Layer SSD PCB

The inherent heat dissipation issues present with 6-layer SSD PCBs are caused by their compact form factor and dense components. Due to multiple layers and limited space, components such as NAND flash chips, controllers, and power management ICs are tightly packed together. Resulting in localized heat build-up and potential hot spots. In addition, the high-speed data transfer rate of the 6 layer SSD PCB will also lead to increased power consumption and heat generation, exacerbating the heat dissipation challenge. As data is transferred between the SSD and the host system, the associated electrical currents generate heat, further increasing the temperature within the device.

Choose the right material

Another aspect is that we use PCB substrates and laminates with high thermal conductivity and low thermal resistance during manufacturing. Materials such as FR-4, FR-4 High Tg, and PI have excellent thermal properties and can efficiently dissipate heat and reduce thermal resistance within the PCB. In addition, we select materials with high glass transition temperatures (Tg) that can withstand high temperatures during operation without compromising mechanical integrity. Because copper has excellent thermal conductivity, it is also the first choice for PCB traces and power planes.

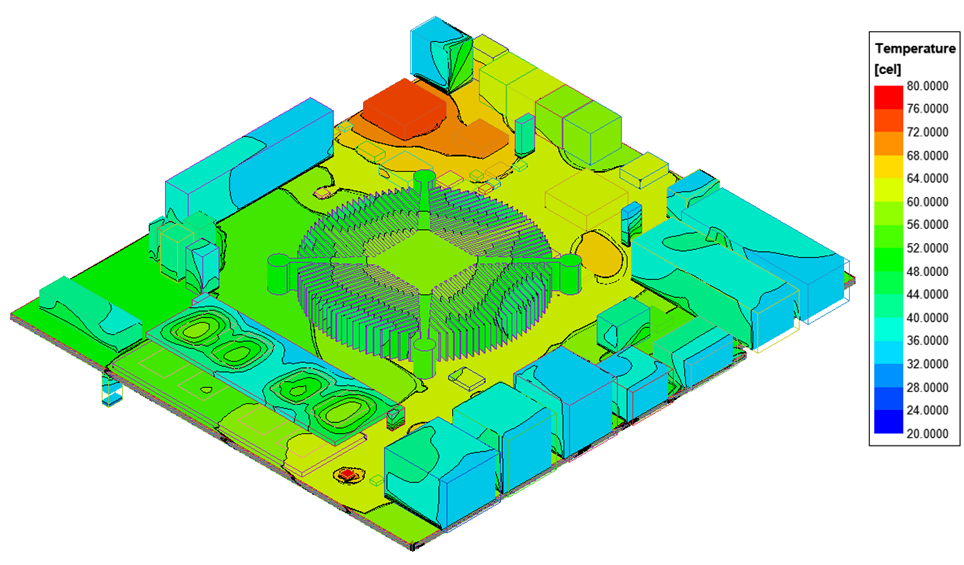

Design 6 layer SSD PCB thermal stability

When we design the thermal stability of the 6-layer SSD PCB, we choose materials with high thermal conductivity and low thermal resistance as well as PCB substrates and laminates with excellent thermal properties for effective heat dissipation, preventing the accumulation of hot spots and ensuring uniform temperature distribution. We will incorporate heat dissipation holes into the 6-layer SSD PCB design to enhance thermal conductivity and facilitate heat dissipation from the inner layer of the circuit board to the outer layer. Targeted placement of thermal vias around high-power components and thermal hot spots effectively diverts heat away from critical areas to maintain thermal stability throughout the 6-layer SSD PCB.

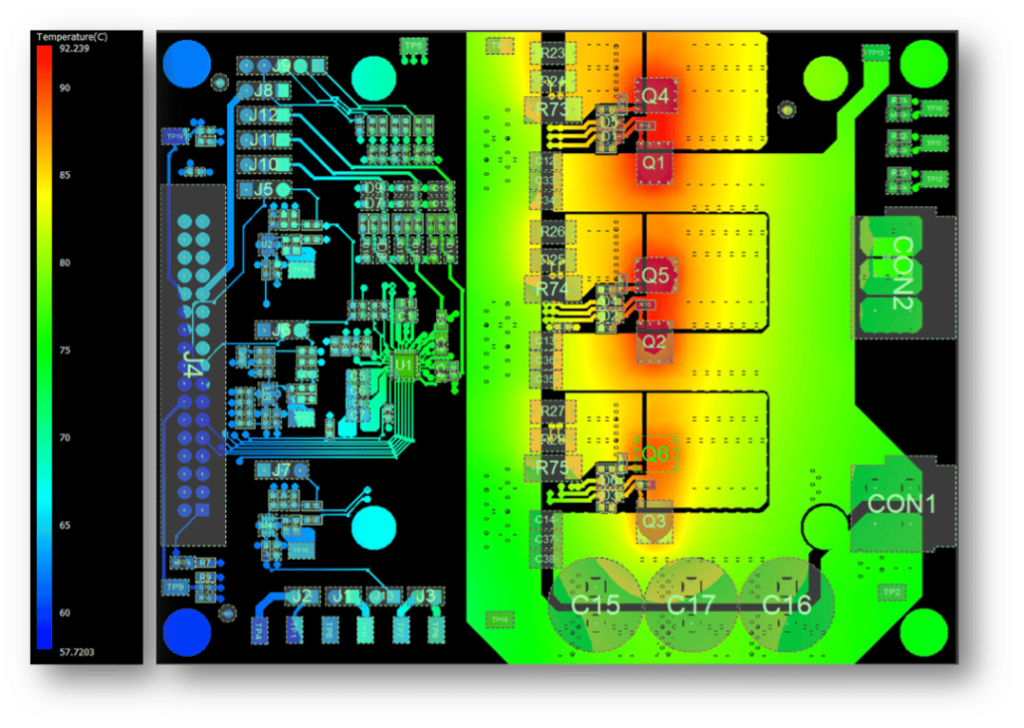

Thermal simulation and analysis of 6 layer SSD PCB

Thermal simulation uses specialized software tools to create detailed thermal models of 6-layer SSD PCBs. These models combine the PCB’s geometric layout, material properties, component layout, and heat generation curves to simulate heat flow and distribution within the circuit board. By accurately representing the physical properties of a PCB, designers can analyze thermal behavior under various operating conditions and identify potential thermal issues.

In addition, our designers use thermal simulation tools to evaluate the impact of different design choices on thermal performance and adjust parameters such as component layout, PCB layout, and material selection. With thermal simulations like this predicting hot spots and temperature gradients on a 6-layer SSD PCB, designers can use additional thermal vias, heat sinks, or insulation to redistribute heat and improve thermal uniformity.

Test and verify

An important aspect of our testing is thermal imaging, which uses an infrared camera to visualize the temperature distribution on the PCB during operation. Thermal imaging provides valuable insights into thermal hotspots, temperature gradients, and potential areas of concern, allowing our designers to proactively identify and resolve thermal issues to adjust thermal management strategies and improve overall thermal performance. In addition, we will conduct thermal cycle testing to evaluate the thermal stability and reliability of the 6-layer SSD PCB under actual operating conditions. During thermal cycling, the PCB undergoes repeated temperature changes within a specified range, simulating the thermal stresses encountered during normal operation. During thermal cycling, I evaluate its ability to withstand temperature fluctuations and identify potential weaknesses or failure modes related to thermal stress.

Ensure product thermal stability and reliability

We will use appropriate design techniques, select high-quality materials, conduct thermal analysis, and implement effective heat dissipation strategies throughout the manufacturing process of 6-layer SSD PCBs to create SSD PCBs that meet the stringent thermal requirements of modern applications.