Double-sided PCB Reflow Soldering Parameter Optimization Guide

In the competitive world of electronics manufacturing, the reflow soldering process is critical to ensuring the quality and reliability of Double-sided PCBs. Mastering the optimization of reflow soldering parameters can significantly improve production efficiency, reduce defects, and enhance overall product performance. As specialists in Double-sided PCB production, we understand the intricacies of this process and aim to provide a comprehensive guide for engineers and purchasers looking to optimize their Double-sided circuit board assembly.

Understanding the Importance of Reflow Soldering for Double-sided PCBs

Double-sided PCBs feature components mounted on both sides of the board, making soldering more complex than on single-sided boards. Reflow soldering ensures that solder paste melts and forms reliable joints between components and the PCB’s copper pads. Optimizing reflow parameters like temperature profiles, conveyor speed, and atmosphere conditions is crucial to avoid issues such as insufficient soldering, solder bridging, or thermal damage to the Double-sided circuit board. Proper control during reflow ensures electrical connectivity, mechanical strength, and long-term durability of the PCB assembly.

Key Reflow Soldering Parameters Affecting Double-sided PCB Quality

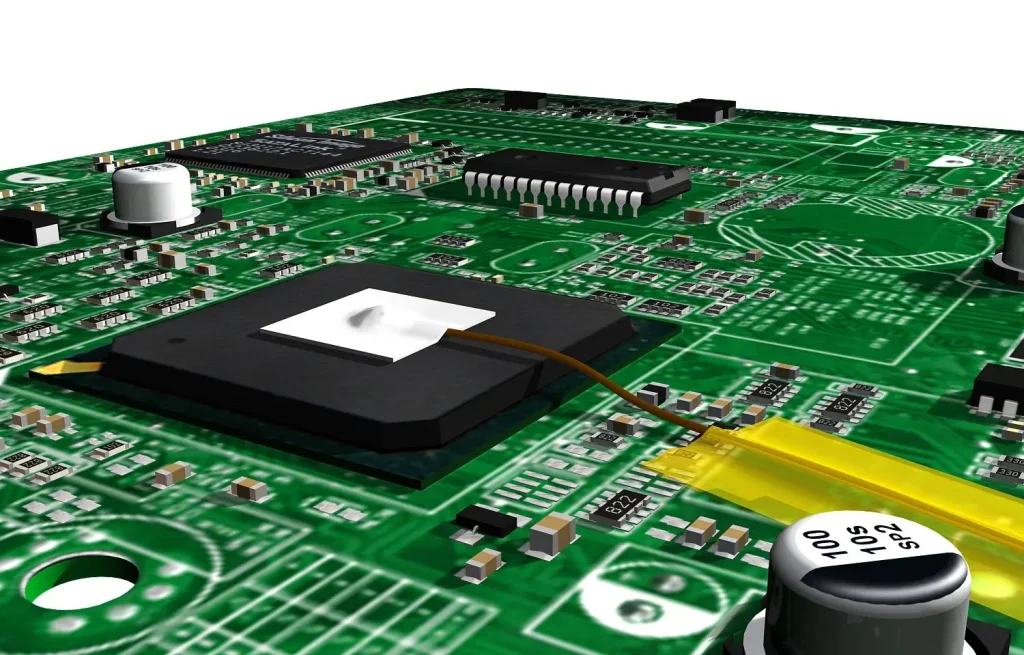

The primary parameters influencing the success of reflow soldering on Double-sided PCBs include preheat temperature, soak time, peak temperature, time above liquidus (TAL), and cooling rate. Each parameter must be carefully calibrated based on the solder paste type, component specifications, and board materials. For instance, too rapid heating can cause thermal shock, while insufficient time above the liquidus may result in poor solder joints. Understanding the thermal mass and heat capacity of a Double-sided circuit board is essential to tailor the reflow profile for consistent, repeatable results effectively.

Profiling Temperature Curves for Double-sided Circuit Boards

Creating an accurate temperature profile is the foundation of optimizing the reflow soldering process for Double-sided PCBs. The profile typically consists of four stages: preheat, soak, reflow (peak), and cooling. During preheat, the board temperature rises gradually to activate flux and evaporate solvents. The soak stage stabilizes temperature across the board to prepare for solder melting. The peak stage melts the solder paste without damaging components or the PCB substrate. Finally, controlled cooling solidifies the solder joints, preventing defects like cracks or warping. Profiling should be verified with thermocouples placed at critical points on the Double-sided circuit board to capture accurate data.

Managing Thermal Challenges in Double-sided PCB Reflow Soldering

Double-sided PCBs are more susceptible to thermal stresses due to components and solder joints on both sides. Managing heat distribution and avoiding uneven temperature gradients is vital to prevent warping, delamination, or component damage. Adjusting conveyor speed and airflow in the reflow oven can help maintain uniform heat application. Additionally, the choice of solder paste and flux chemistry can influence thermal tolerance. Engineers must balance thermal input to achieve reliable solder joints while preserving the integrity of the Double-sided circuit board and its components.

Equipment Considerations for Optimized Double-sided PCB Reflow

Modern reflow ovens equipped with multiple heating zones, programmable temperature control, and nitrogen atmospheres offer enhanced precision for Double-sided PCB soldering. Zone-based control allows for gradual heating and cooling tailored to the board’s specific needs. Nitrogen environments reduce oxidation, improving solder quality and reliability. Selecting appropriate conveyor speeds and ensuring regular maintenance of the reflow oven also contribute significantly to parameter optimization. These equipment factors work synergistically with process parameters to maximize yield and minimize defects in Double-sided circuit board production.

Troubleshooting Common Reflow Soldering Issues in Double-sided PCBs

Even with optimized parameters, issues such as solder bridging, tombstoning, voids, and insufficient wetting can arise during Double-sided PCB assembly. Diagnosing these problems requires analyzing the thermal profile, solder paste application, and component placement accuracy. For example, excessive peak temperatures may cause solder balling, while unevenly distributed solder paste can lead to bridging. Implementing real-time monitoring and post-process inspection techniques, such as X-ray and automated optical inspection (AOI), helps identify defects early. Continuous feedback loops enable fine-tuning of reflow parameters to address recurring challenges effectively.

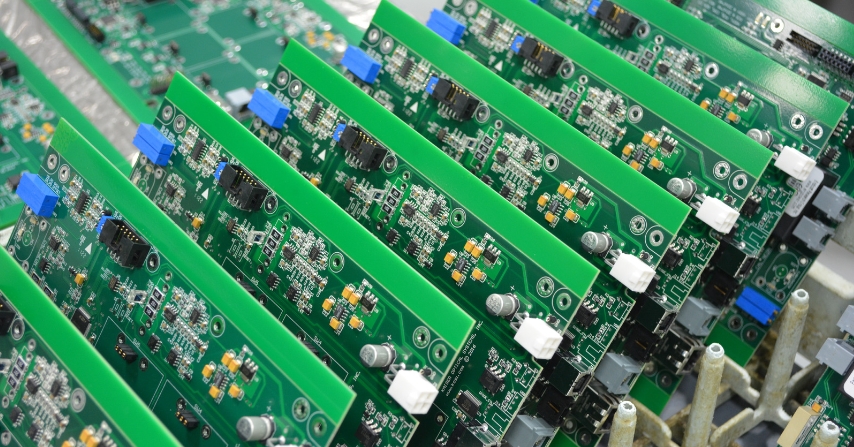

Best Practices for Continuous Improvement in Double-sided PCB Reflow Soldering

Achieving consistent quality in Double-sided circuit board soldering demands a culture of continuous process optimization. Regularly reviewing production data, conducting thermal profile audits, and updating solder paste specifications in line with supplier innovations can enhance performance. Training operators to understand the impact of reflow parameters on solder joint quality further supports reliability. Additionally, embracing Industry 4.0 technologies, such as IoT-enabled ovens and AI-driven analytics, can enable predictive maintenance and real-time adjustments, ensuring the Double-sided PCB manufacturing process remains robust and efficient.