Double Sided FR4 PCB Solder Mask Types and Their Applications

Double sided FR4 PCB technology plays a vital role in electronics manufacturing because of its versatility and reliability. The choice of solder mask on double-sided FR4 PCBs directly affects its performance, durability, and manufacturability. Selecting the appropriate solder mask type enhances protection against environmental factors, improves assembly precision, and strengthens electrical insulation for these dual-layer FR4 circuit boards.

Understanding Double-Sided FR4 PCB and Its Importance in Solder Mask Selection

A double-sided FR4 PCB features conductive traces on both sides of the fiberglass-reinforced epoxy laminate substrate known as FR4. This dual-layer design enables more complex circuit layouts within a compact footprint, meeting the demands of modern electronics. However, the double-sided structure introduces challenges in soldering and protection, which make the solder mask an essential component. The solder mask acts as a protective coating that prevents solder bridging, oxidation, and electrical shorts while maintaining circuit integrity during manufacturing and operation.

Choosing the proper solder mask ensures the longevity and performance of the dual-layer FR4 circuit board by improving resistance to moisture, dust, chemicals, and mechanical damage. It also helps manufacturers achieve fine-pitch component placement by improving soldering accuracy, a critical factor in high-density electronic designs.

Types of Solder Masks Used for Double-Sided FR4 PCB

Manufacturers use several solder mask types in double-sided FR4 PCB production. The most common are liquid photoimageable solder masks (LPI), dry film solder masks (DFSM), and peelable solder masks. Each offers distinct advantages suited for different production needs:

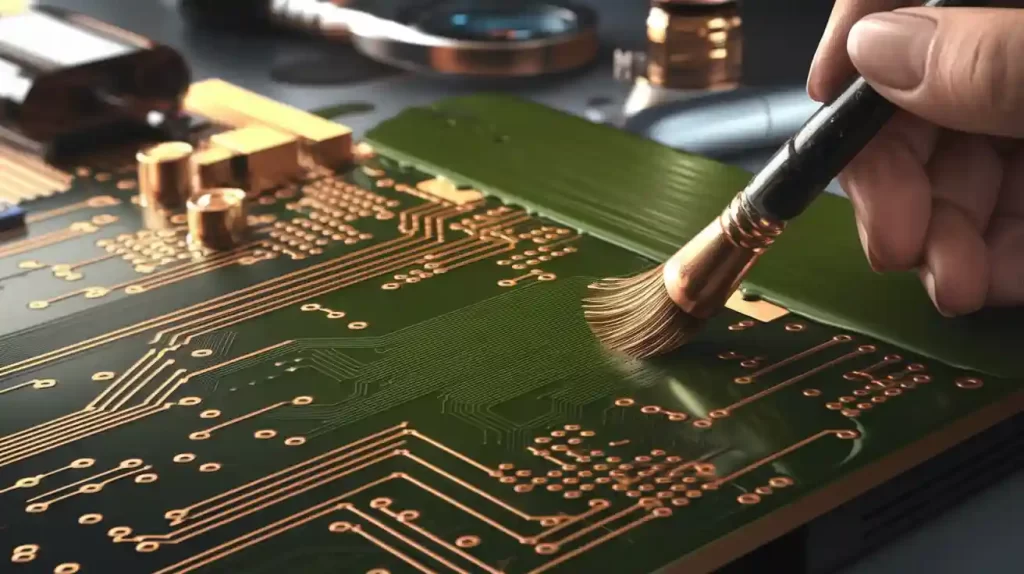

- Liquid Photoimageable Solder Mask (LPI): This widely used type provides excellent resolution and coverage. Manufacturers apply LPI as a liquid and cure it under UV light, allowing precise patterning suited for fine-pitch components on dual-layer boards.

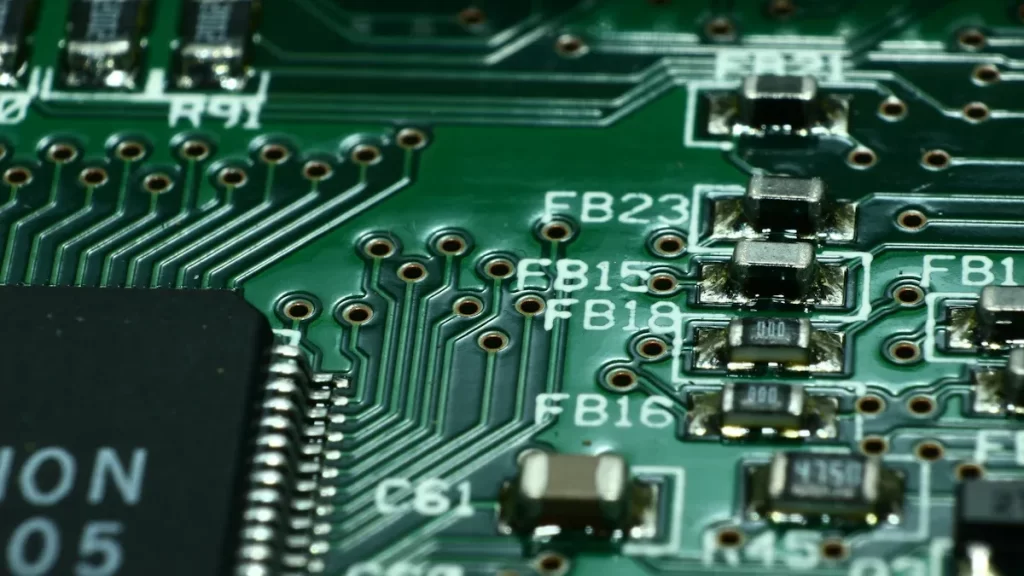

- Dry Film Solder Mask (DFSM): Laminated as a solid film, DFSM provides uniform thickness and superior mechanical protection. It suits industrial-grade Double Sided FR4 PCBs that require a thicker solder mask layer.

- Peelable Solder Mask: Manufacturers apply this temporary mask during wave soldering to prevent solder bridging in specific areas. They remove it after assembly completes.

Choosing the right solder mask depends on the complexity of the dual-layer FR4 circuit board design, production volume, and the intended operating environment.

Benefits of Employing High-Quality Solder Masks in PCB Manufacturing

Applying advanced solder masks improves manufacturing yields and product reliability on Double-Sided FR4 PCBs. These masks enhance solderability, prevent short circuits, and shield circuits from environmental stressors like humidity and corrosion. For example, LPI solder masks offer strong adhesion and chemical resistance, which proves essential in automotive electronics that endure harsh conditions.

Solder masks also improve electrical performance by minimizing parasitic capacitance and crosstalk, critical in high-frequency applications common in medical devices and consumer electronics. They facilitate automated inspection and assembly, reducing defects and downtime in production lines.

Solder Mask Applications in Industrial Control Systems

Industrial control systems require highly reliable PCBs that withstand extreme conditions. Manufacturers favor Double Sided FR4 PCBs with high-performance solder masks, such as DFSM, because these masks provide robust insulation and protection. They shield circuits from chemical exposure, dust, and mechanical wear, common in factory environments. LPI solder masks ensure precise connections for sensors and actuators within complex control modules. Their precision enables the integration of more control functions into compact dual-layer boards, making them ideal for modern industrial automation.

Role of Solder Mask Types in Automotive Double-Sided FR4 PCB Applications

The automotive industry demands PCB materials and coatings that endure vibration, temperature swings, and humidity. Automotive-grade solder masks for Double Sided FR4 PCBs must adhere strongly, withstand heat, and resist corrosion. Manufacturers primarily use liquid photoimageable solder masks for automotive dual-layer FR4 circuit boards because these masks resist thermal cycling and mechanical stress without cracking or peeling. This durability ensures that critical systems, such as engine control units, infotainment systems, and safety devices, remain reliable throughout a vehicle’s lifetime.

Customizing Solder Mask Selection for Consumer Electronics and Medical Devices

Consumer electronics require compact, lightweight, and reliable PCBs. LPI solder masks enable miniaturization by supporting high-density circuit patterns and precise soldering on double-sided FR4 PCBs. Besides functionality, solder masks improve aesthetics by offering smooth, colorful surfaces preferred in consumer gadgets.

In medical devices, manufacturers must ensure biocompatibility and resistance to sterilization processes. Medical-grade solder masks on dual-layer FR4 circuit boards prevent harmful substances from leaching and help withstand repeated cleaning cycles. These protections ensure devices like diagnostic tools and wearable monitors perform consistently in sensitive healthcare environments.

Summary and Future Outlook for Double-Sided FR4 PCB Solder Mask Technologies

As electronics evolve, solder masks are increasingly important for boosting the performance of double-sided FR4 PCBs. Manufacturers are developing new solder mask materials with improved thermal and chemical resistance to support reliable dual-layer boards in demanding conditions. Engineers must balance production efficiency, environmental protection, and electrical performance when selecting solder masks. Staying informed about solder mask innovations enables designers to optimize dual-layer FR4 circuit board applications in industrial control, automotive, consumer electronics, and medical sectors. Choosing the right solder mask extends product life, improves manufacturing yield, and increases customer satisfaction.