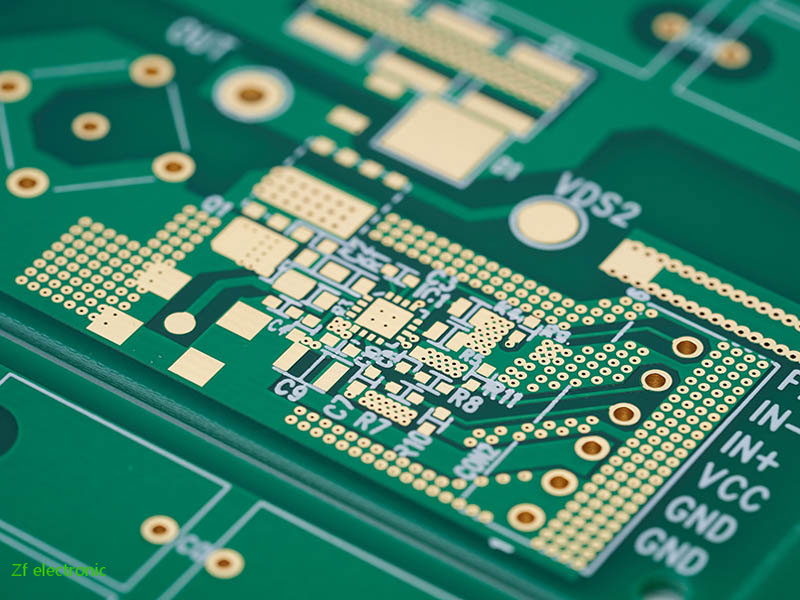

Double Side PCB Manufacturing Tips for Consistent Quality

Producing high-quality double-side PCB boards requires precision and attention to detail. Manufacturers must strike a balance between efficiency and quality to ensure reliable performance. Errors in design, material, or assembly can lead to failures. Understanding best practices in each stage improves consistency. This article highlights key tips for achieving reliable double-sided PCB manufacturing outcomes.

Selecting High-Quality Materials

The foundation of a reliable Double-Sided PCB is high-quality materials. Selecting the correct copper thickness, substrate, and laminate has a significant impact on performance. Materials must resist heat and chemical exposure during processing. Engineers should verify supplier certifications and the properties of the materials. Using consistent materials ensures dimensional stability and signal integrity. Proper material selection minimizes defects and improves overall board reliability. High-quality substrates have a direct impact on manufacturing success and consistent Double-Sided PCB results.

Accurate Design and Layout

Design accuracy is crucial for ensuring the consistency of Double-Sided PCBs. Engineers should follow standardized design rules. Maintain proper trace width, spacing, and pad sizes to ensure optimal performance. Align holes and vias precisely to avoid misregistration. Simulation tools help detect potential issues before production. Double-checking the layout reduces manufacturing errors and rework. Proper design also simplifies soldering and assembly processes. A meticulous layout is crucial for achieving consistent, high-quality double-sided PCB production.

Drilling and Via Alignment

Drilling is a crucial step in the manufacturing of Double-Sided PCBs. Misaligned holes can cause electrical failure or assembly issues. Providers should use CNC machines with high precision. Inspect hole diameters and plating for uniformity. Through-hole plating ensures strong electrical connections between layers. Proper alignment also reduces the risk of short circuits and mechanical stress. Consistent drilling practices directly contribute to the reliability and high performance of Double-Side PCB boards.

Copper Plating and Etching Control

The quality of copper plating determines the integrity of circuits on double-sided PCB boards. Plating thickness must meet design specifications. Uneven plating leads to weak traces or open circuits. Etching processes remove excess copper while preserving pattern accuracy. Controlling chemical concentration, temperature, and timing is essential. Continuous monitoring and testing prevent over-etching or under-etching. Reliable plating and etching ensure the functional circuits and long-term durability of Double-Side PCB boards.

Solder Mask Application

The solder mask protects circuits during assembly and operation. Applying a uniform layer prevents solder bridges and shorts. Inspect for coverage gaps and alignment on both sides. Use high-quality, UV-resistant masks to prevent discoloration and degradation. Correct curing improves adhesion and resistance to thermal cycles. Engineers should consistently verify the thickness and adhesion of the mask. Proper solder mask application ensures reliable and consistent Double-Sided PCB production quality.

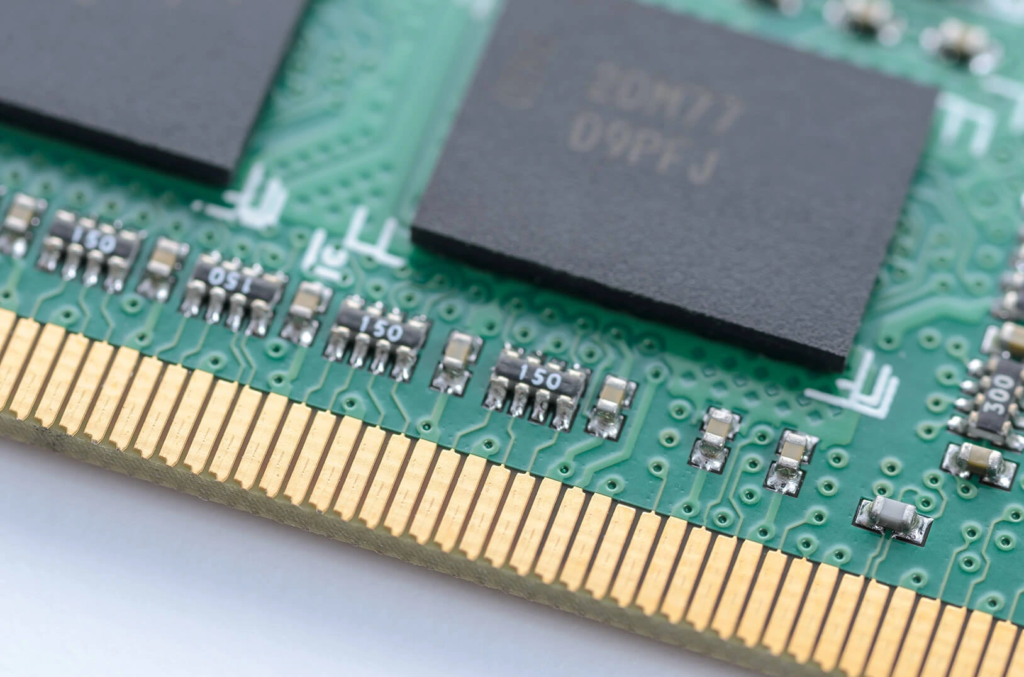

Surface Finish and Component Mounting

Surface finish affects solderability and component reliability. Standard finishes include HASL, ENIG, and OSP. Select a finish that is compatible with the assembly methods and operating conditions of the product. Component placement should align with design tolerances. Automated pick-and-place machines reduce human error. Inspection ensures all pads and leads are correctly positioned. Maintaining surface quality and accurate mounting improves overall board performance. These steps are critical for producing durable double-sided PCB assemblies.

Testing and Quality Assurance

Comprehensive testing ensures that every Double-Sided PCB meets specifications. Use electrical tests, such as a flying probe or bed-of-nails, to detect opens and shorts. Visual inspection and AOI systems catch surface defects. Functional testing verifies circuits operate correctly under load. Consistently applying these tests prevents faulty boards from reaching customers. Quality assurance is the final checkpoint that ensures high standards in Double-Sided PCB manufacturing.

Double-Side PCB Process Optimization and Continuous Improvement

Manufacturing efficiency improves with continuous process optimization. Track yield, defect rates, and machine performance—train staff regularly on best practices and emerging technologies. Implement feedback loops to correct recurring issues. Process documentation ensures repeatable results. Leveraging lessons learned supports long-term consistency and cost savings. A commitment to continuous improvement enhances overall product quality, providing consistent Double Side PCB manufacturing outcomes.