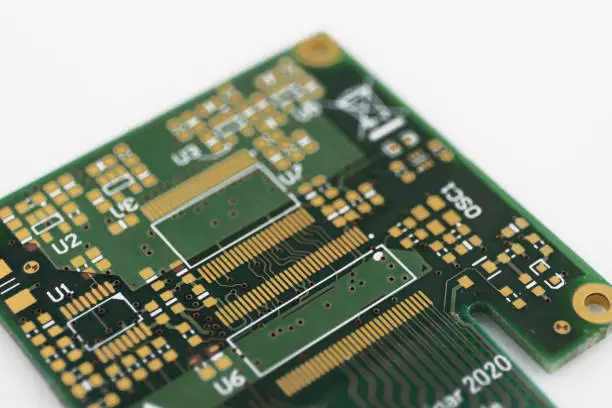

Comparing SSD PCB Base Materials: FR4, Polyimide, or BT Resin?

The base material can make or break performance when designing a reliable SSD PCB. As the demand for high-speed data storage grows, engineers and manufacturers face increasing pressure to select substrates that offer electrical stability, thermal endurance, and mechanical reliability. FR4, Polyimide, and BT Resin are the primary contenders in this arena. Each comes with unique advantages and trade-offs that influence the final performance and cost of the SSD.

FR4: The Industry Standard with Budget Appeal

FR4 is the most widely used base material in the PCB industry. Made of woven fibreglass cloth and epoxy resin, it offers a solid balance of electrical insulation, mechanical strength, and cost efficiency. This material is particularly attractive for consumer-grade SSDs where moderate performance and low cost are essential.

However, FR4 has limitations. Its relatively low glass transition temperature (TG), usually around 130–140°C, restricts its application in high-temperature environments. Additionally, its dielectric constant and loss tangent can affect signal integrity at high frequencies. Despite these drawbacks, FR4 remains a viable choice for many designs due to its widespread availability, ease of processing, and low manufacturing costs.

Polyimide: High-End Performance for Rugged Applications

Polyimide is the go-to material for high-performance SSD PCB applications where thermal resistance and flexibility are crucial. Known for its high TG of over 250°C, polyimide maintains structural integrity in extreme conditions. This makes it ideal for aerospace, automotive, and industrial environments where reliability is non-negotiable.

On the downside, polyimide is significantly more expensive than FR4. It also requires specialised handling during fabrication, which can increase production complexity and cost. However, the trade-off is often worth it for mission-critical applications. Polyimide provides unmatched stability and endurance if your SSD needs to operate in extreme thermal or mechanical environments.

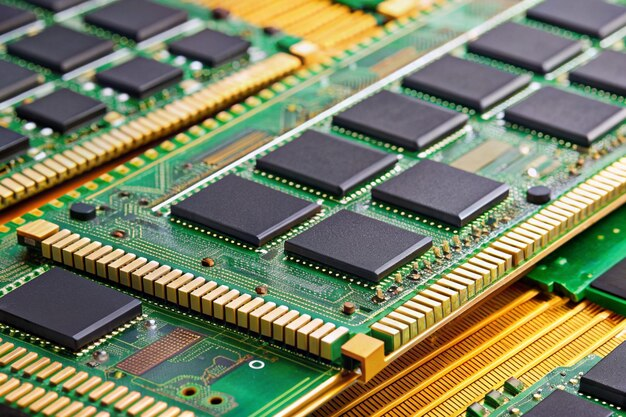

BT Resin: Balanced Performance for Mid-Range Needs

BT Resin, a blend of bismaleimide triazine compounds, sits between FR4 and polyimide in terms of performance and cost. It offers better thermal stability than FR4 and more affordable manufacturing than polyimide. Its TG typically falls between 170–200°C, making it suitable for high-density SSD PCB designs with improved signal integrity.

Furthermore, BT resin exhibits lower moisture absorption and better dimensional stability, critical in multilayer SSD applications. Its dielectric properties also contribute to reduced signal loss at higher frequencies. For manufacturers seeking a middle ground—better than FR4 but not as costly as polyimide—BT Resin is often the ideal compromise.

Comparing Electrical Performance Metrics

Signal integrity is a key concern in SSD PCB design. As data rates increase, the electrical properties of the base material become increasingly important. FR4 exhibits greater signal distortion with its higher dielectric constant than polyimide and BT Resin, making it less ideal for high-speed data transfer.

BT Resin outperforms FR4 in impedance control and supports cleaner signal transmission. Polyimide, while excellent, requires careful design and layout to optimise its advantages. In applications requiring gigabit-level data rates, polyimide and BT Resin offer superior performance to maintain low error rates and high efficiency.

Thermal and Mechanical Reliability Under Stress

Thermal performance is another vital consideration. SSDs generate significant heat during high-speed operations, and base materials must dissipate this heat without warping or delaminating. FR4 falls short in high-heat conditions, while BT Resin and polyimide provide better thermal management.

Mechanical strength also plays a role, especially for SSDs exposed to vibrations or physical stress. Polyimide excels in flexibility and tensile strength, making it resilient in harsh environments. BT Resin also offers good mechanical stability, though not as robust as polyimide. FR4 is adequate for less demanding applications but lacks the durability of its counterparts.

Manufacturing Considerations and Scalability

From a production standpoint, FR4 remains the most accessible option. It supports various PCB fabrication processes and requires less stringent handling protocols. Polyimide and BT Resin, however, demand specialised lamination and etching processes. This adds to production time and cost, but may be justified by the performance benefits.

Another consideration is scalability. FR4’s ubiquity makes it easy to scale for large-volume SSD PCB production. Polyimide and BT Resin, while scalable, are often reserved for high-value, lower-volume applications due to their cost. Understanding these trade-offs helps manufacturers plan both prototype and mass production runs efficiently.

Use Cases and Industry Trends for SSD Raw Materials

Different industries favour different base materials depending on their operational demands. Consumer electronics often use FR4 for budget SSDs. Enterprise storage systems lean toward BT Resin for its balance of performance and cost. Mission-critical sectors like aerospace and defence almost exclusively use polyimide due to its unmatched reliability.

Emerging trends also influence material choices. As SSDs become thinner and faster, demand for materials that support micro vias and HDI (High-Density Interconnect) design is growing. BT Resin and polyimide are better suited for these advanced technologies. Consequently, the market is gradually shifting away from FR4 in high-performance segments.

Making the Right Choice for Your SSD PCB

Selecting the right material for your SSD PCBs—whether FR4, polyimide, or BT resin—matches technical demands with practical constraints. FR4 remains a reliable, low-cost option for standard applications. Polyimide stands out in environments where heat and stress are critical factors. BT resin, meanwhile, offers the best overall balance for high-speed, high-density designs. Understanding each material’s strengths and trade-offs ensures your SSD performs reliably and efficiently in its intended use case.