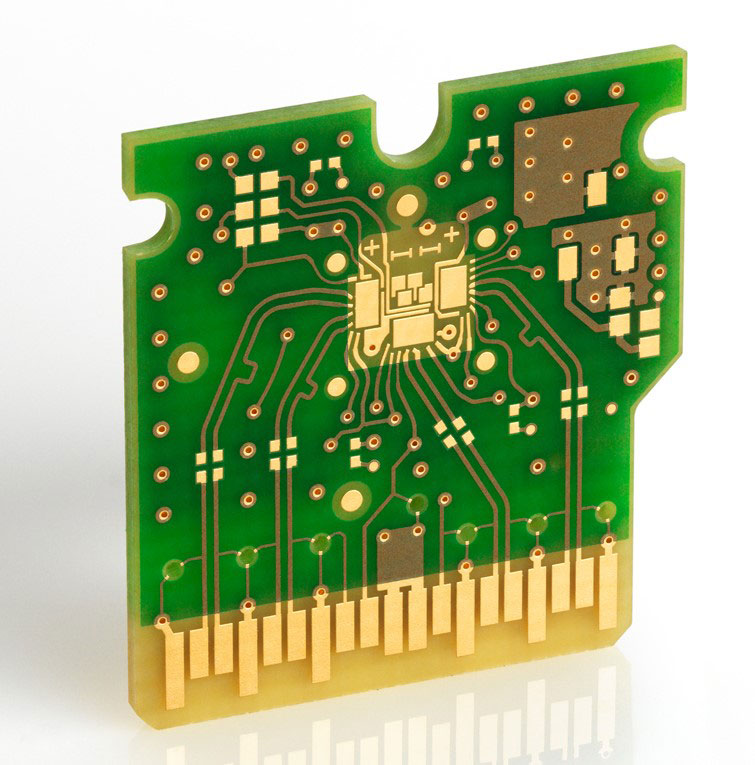

Gold Finger PCB connectors are essential components for reliable electronic performance. They provide durable, low-resistance connections between printed circuit boards and devices. However, repeated insertion, environmental exposure, and improper handling can cause wear, corrosion, or contamination. Proper inspection and maintenance prevent failure, extend service life, and maintain signal integrity. Understanding these best practices helps engineers […]

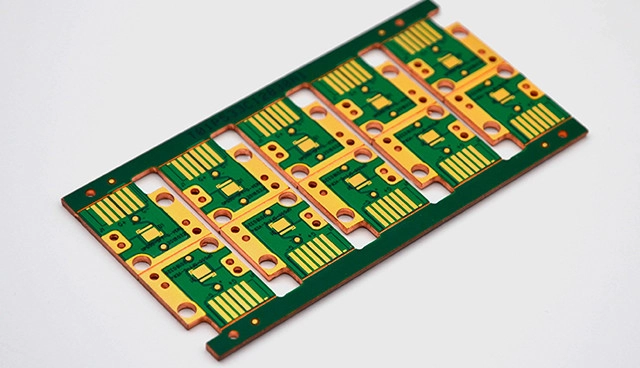

High-voltage power systems demand reliable and durable circuit boards that can consistently deliver stable performance. A Heavy Copper PCB is designed to handle large currents and high voltages without failure, making it a trusted choice in demanding applications. Unlike standard PCBs, these boards feature much thicker copper layers. This unique design improves electrical performance, enhances […]

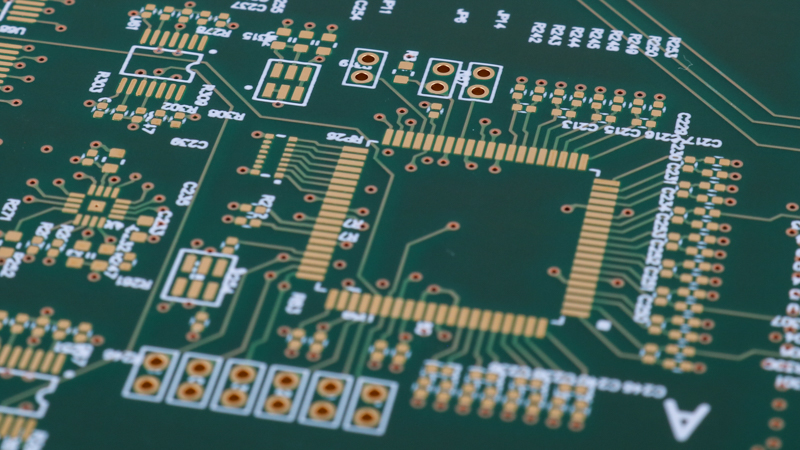

Producing high-quality double-side PCB boards requires precision and attention to detail. Manufacturers must strike a balance between efficiency and quality to ensure reliable performance. Errors in design, material, or assembly can lead to failures. Understanding best practices in each stage improves consistency. This article highlights key tips for achieving reliable double-sided PCB manufacturing outcomes. Selecting […]

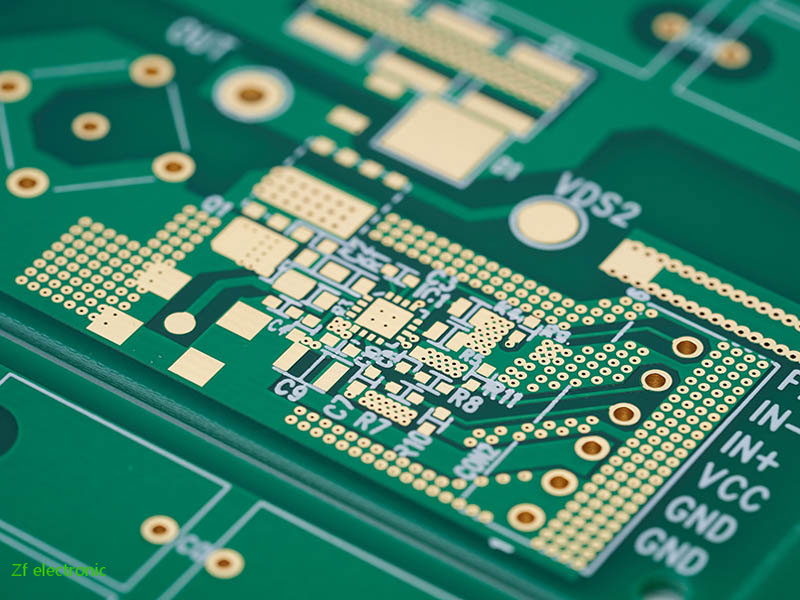

IoT smart appliances demand reliable links. They also require compact electronics and low power. Consequently, board design now defines device performance. High-density interconnect (HDI) PCBs answer many of those needs. They pack traces, vias, and components more tightly. As a result, signal integrity and RF performance improve. Moreover, HDI PCB lets designers place radios and […]

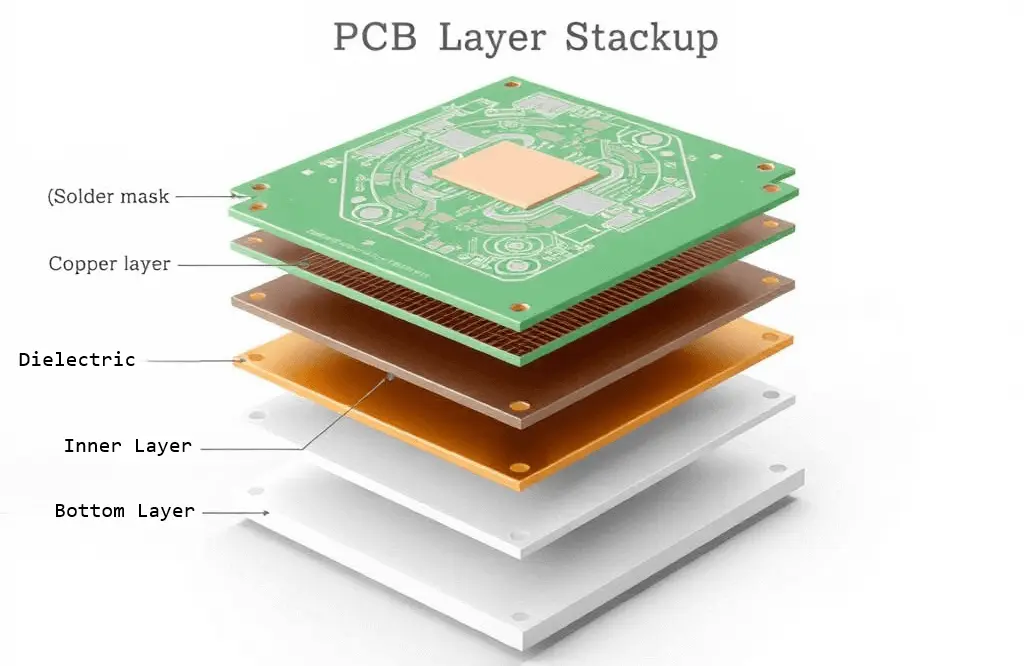

Solid-state drives (SSDs) require high-speed, reliable connections. Modern storage systems depend on stable signal paths and robust thermal performance. A poorly printed circuit board can cause data loss, latency, or failure. A multi-layer PCB architecture addresses these challenges by providing multiple conductive layers, improving signal integrity, and enhancing power distribution. Let’s explore how multi-layer designs […]

Set-top Box SMT assembly lines often face defects that reduce yields and increase costs. To maintain quality, identify root causes, and optimise processes. Start with PCB inspection, solder paste control, and component placement. Meanwhile, monitor reflow profiles and operator handling. Proper training and consistent procedures help prevent mistakes and also facilitate the recording of data […]

Multilayer PCBs (printed circuit boards) are crucial for high-frequency electronics due to their compact design and superior signal integrity. They play a crucial role in applications such as radio frequency communications, high-speed data transmission, and precision measuring instruments. So, how should we construct multilayer PCBs for high-frequency electronics? What key design factors, materials, and manufacturing […]

Parylene Nano Vacuum Coating provides electronics with a thin, uniform barrier that helps assemblies withstand harsh environments. In many field cases, even minor defects can cause early failures. Therefore, engineers use this coating to block moisture, contaminants, and corrosion. Moreover, it conforms to complex geometries without adding bulk. As a result, teams protect sensitive circuits […]

Selecting the appropriate dielectric material is crucial for PCBs, particularly for a high frequency PCB. You need a dielectric material with a stable dielectric constant and a low loss tangent. This is non-negotiable. If the material fails to maintain its electrical properties at high frequencies, signal degradation and electromagnetic interference (EMI) issues can occur. If […]

A robust PCB stackup starts with the appropriate number of layers, copper thickness, and proper layout of ground and power planes. Material selection is also crucial. For high-current designs, such as motor drives or inverters, thick copper PCBs are often preferred due to their ability to handle high currents. They provide a low-impedance power path […]