Ceramic PCBs have become essential in high-frequency circuit design. They outperform traditional PCBs due to their exceptional heat dissipation, electrical insulation, and mechanical stability. The Ceramic PCB is ideal for industries such as telecommunications, aerospace, automotive, and power electronics, where performance and reliability are crucial. As the demand for high-frequency devices, such as 5G communication […]

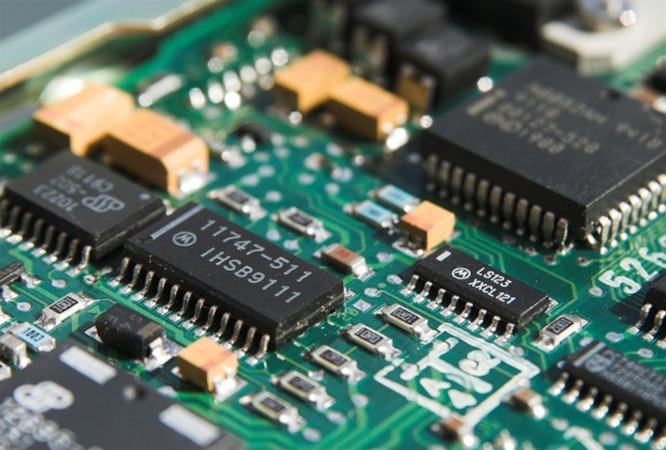

In the competitive world of electronics manufacturing, the reflow soldering process is critical to ensuring the quality and reliability of Double-sided PCBs. Mastering the optimization of reflow soldering parameters can significantly improve production efficiency, reduce defects, and enhance overall product performance. As specialists in Double-sided PCB production, we understand the intricacies of this process and […]

Heavy Copper PCBs are becoming essential enablers as the demand for higher efficiency, performance, and reliability in power electronics grows at an unprecedented rate. These specialized printed circuit boards (PCBs) use thicker copper layers to meet the growing demands of high-current applications. They also improve thermal management and enhance mechanical stability. This article explores the […]

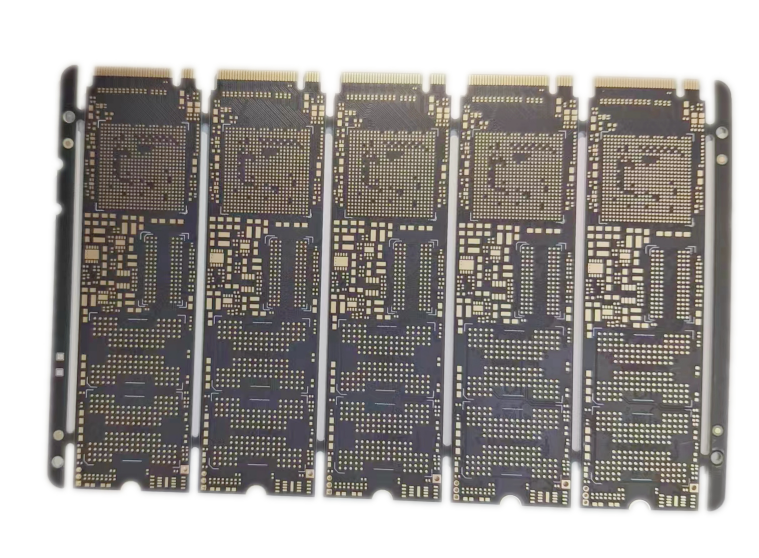

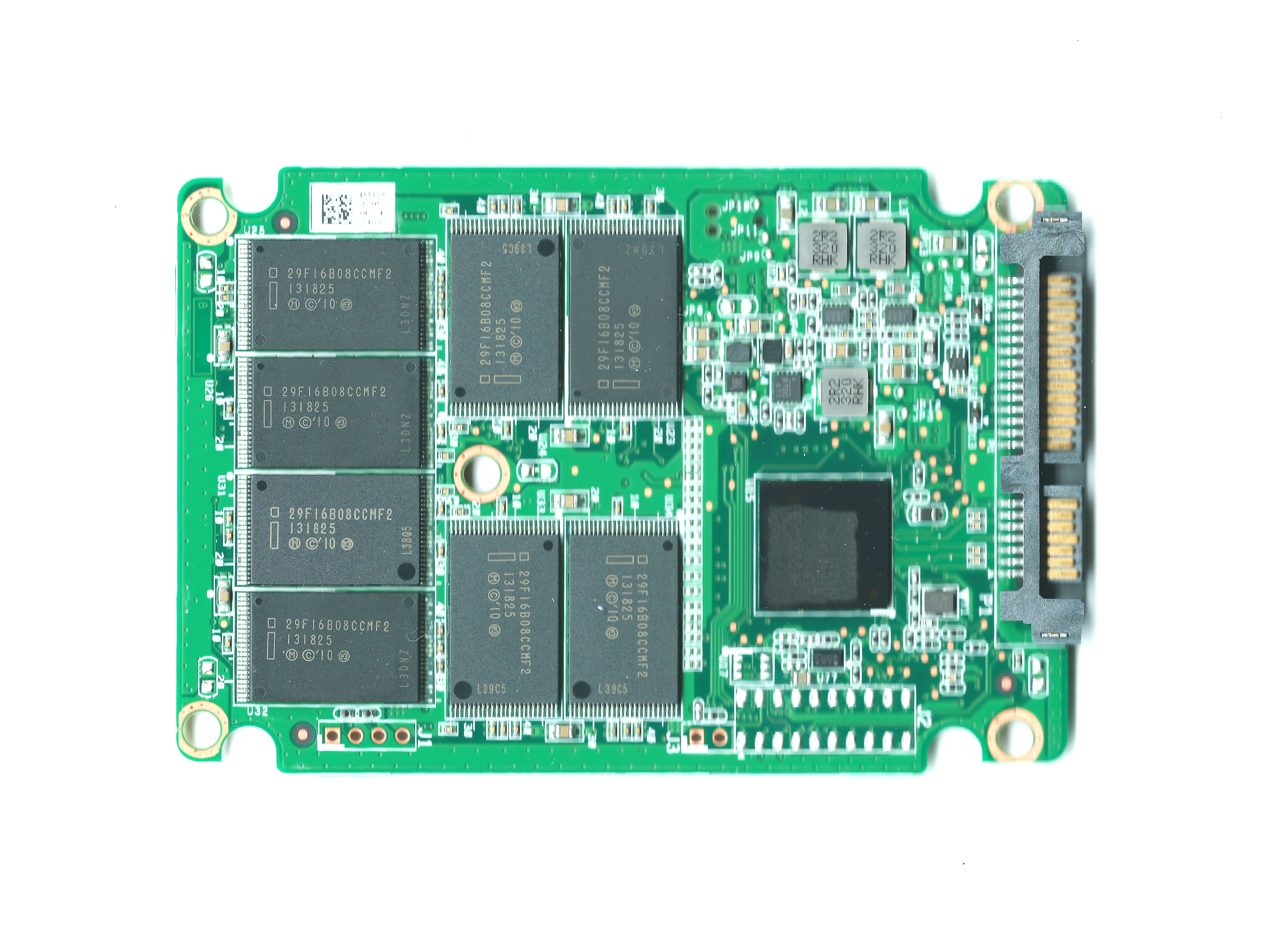

SSD PCB solutions are printed circuit boards designed specifically for solid-state storage. Their performance requirements extend beyond speed to include stability, durability, and signal integrity, and they are widely used in consumer electronics, enterprise storage, and high-performance computing. Solid-state drive PCB manufacturing focuses on long-term storage reliability, with its design, development, and production adhering to […]

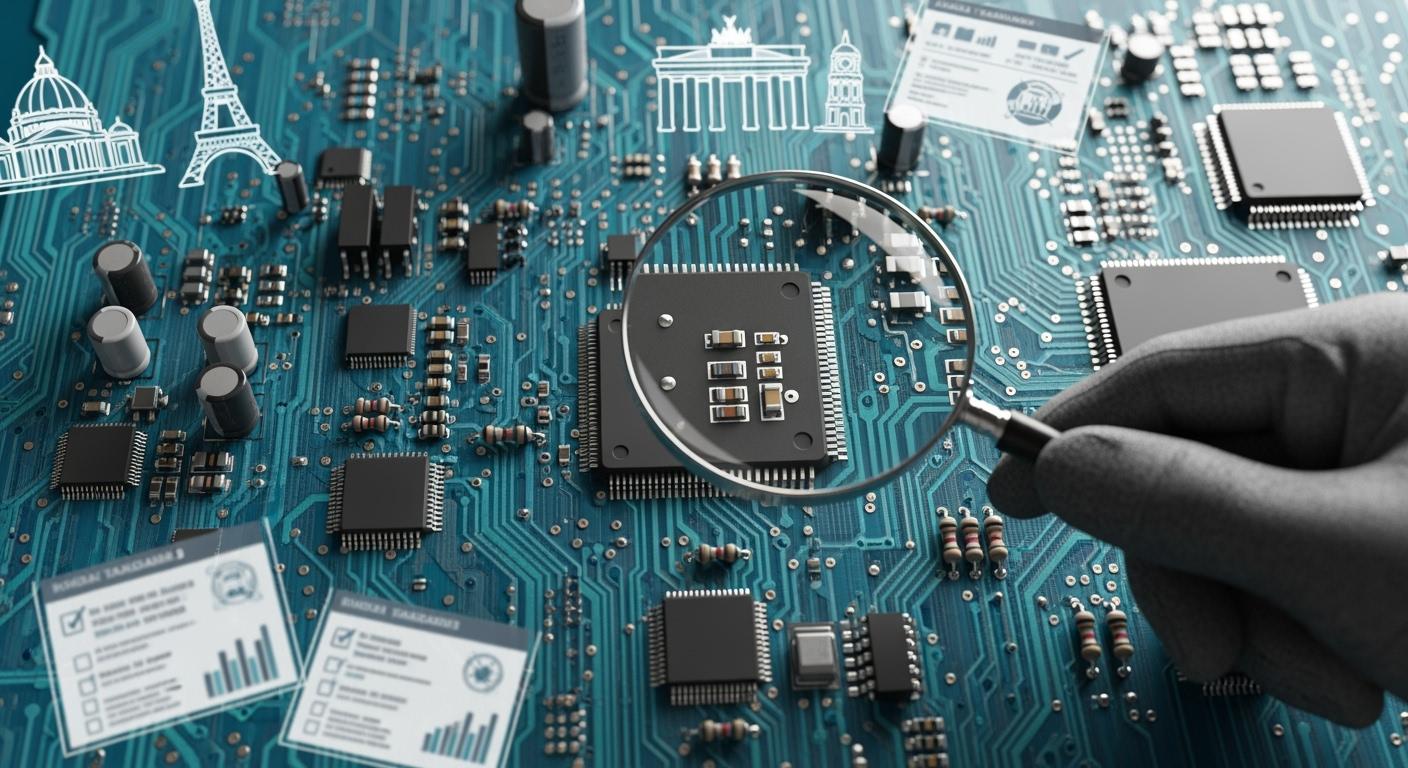

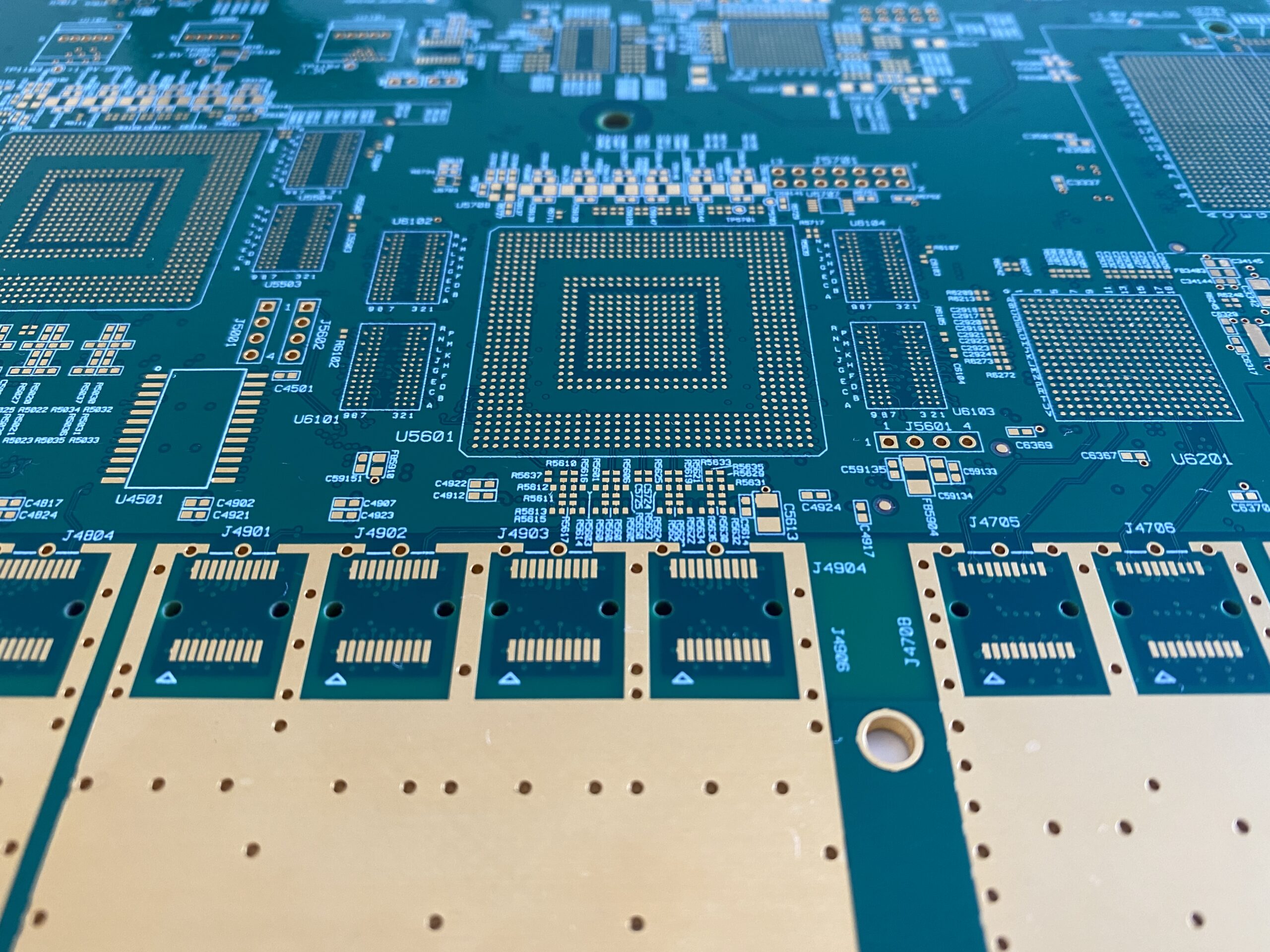

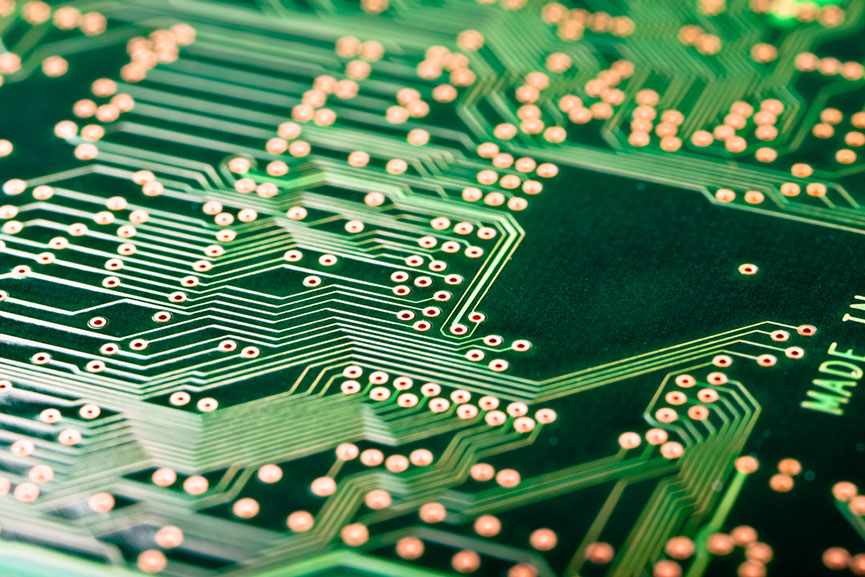

In modern electronics, complex circuits demand high density, high speed, and reliable signal integrity. Using an advanced printed circuit board (PCB) architecture can greatly ease that. Among those architectures, “HDI PCB” stands out. In this post, I explain how HDI PCBe designs help cut down signal interference in complex circuits. I base the arguments on […]

Power-dense electronics place significant stress on printed circuit boards. Standard PCBs often fail to manage heat when designers push them to the limit. In those cases, a board built with thick copper — a heavy copper PCB — wins. Heavy copper dramatically improves thermal conduction. As a result, engineers can build dense boards that stay […]

SSD PCB Trends: What the Next Generation Storage Modules Hold for the SSD Market. The SSD market is expanding rapidly as data-driven technologies dominate the global economy. From hyperscale data centers to high-end gaming laptops, every device now demands faster storage. This growth has put tremendous pressure on the SSD PCB, which serves as the […]

Printed circuit boards are the backbone of the electronics industry. Choosing between a double-sided PCB and a multilayer board can directly influence both cost and performance. In many cases, companies find that using a double-sided PCB strikes a balance between reliability and affordability, especially when design complexity does not require advanced stack-ups. Let’s dive into […]

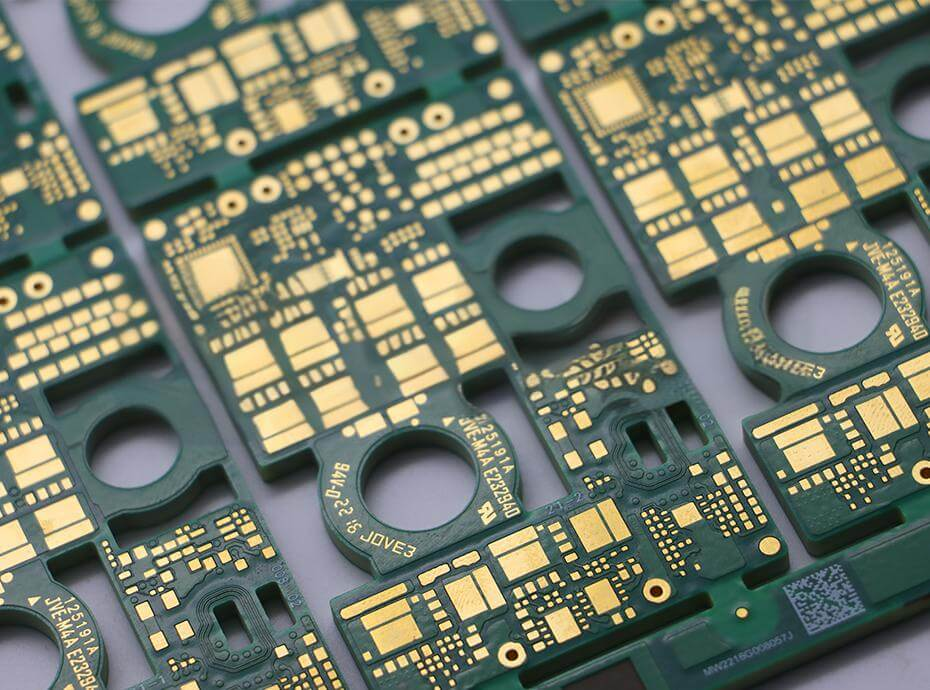

Printed circuit boards often rely on edge connectors for fast and reliable communication. Gold finger PCB connectors play a critical role in maintaining high-frequency signal integrity across many industries. Their design, plating quality, and geometry have a direct impact on performance, particularly in advanced computing and telecommunications. Why Gold Plating Matters in High-Frequency Applications Gold […]

Printed circuit board technology continues to evolve rapidly. As 2025 approaches, PCB manufacturing faces both challenges and opportunities. Companies must track key trends to remain competitive and meet growing demands from the automotive, telecom, and consumer electronics sectors. Shift Toward Advanced Materials One of the most substantial shifts in PCB manufacturing is the adoption of […]