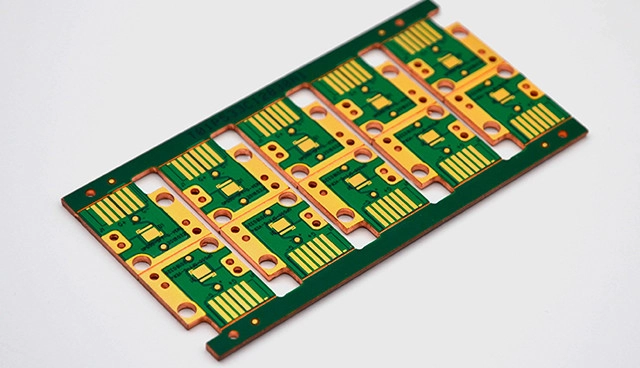

Heavy Copper PCB for Reliable High Voltage Power Distribution

High-voltage power systems demand reliable and durable circuit boards that can consistently deliver stable performance. A Heavy Copper PCB is designed to handle large currents and high voltages without failure, making it a trusted choice in demanding applications. Unlike standard PCBs, these boards feature much thicker copper layers. This unique design improves electrical performance, enhances mechanical stability, and increases longevity in industrial and commercial power applications.

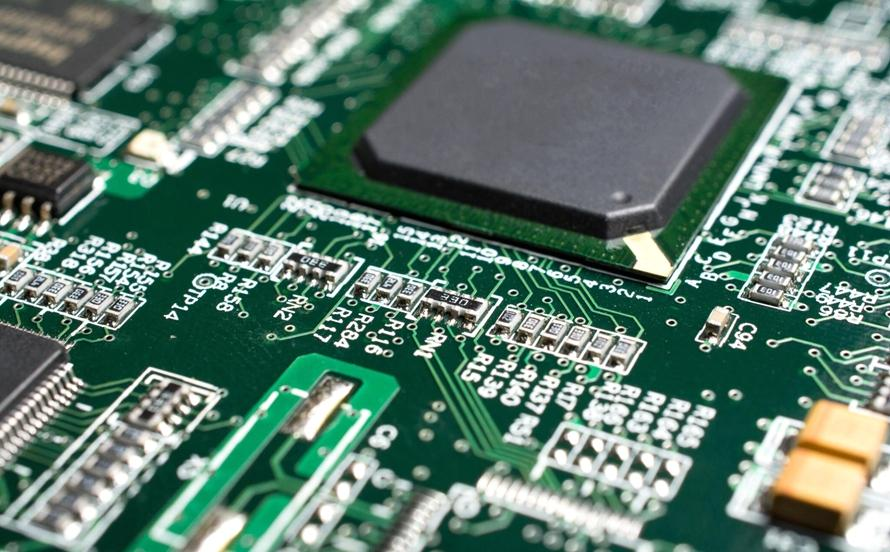

Enhanced Current Carrying Capacity

The most important benefit of a Heavy Copper PCB is its ability to carry higher currents safely and efficiently. Thick copper traces distribute power more evenly, preventing overheating during extended operation. As a result, power electronics can operate without risk, even under extreme load conditions. Engineers rely on these boards when designing transformers, inverters, and industrial control systems that require uninterrupted power. The additional copper thickness ensures that electrical paths remain stable, reliable, and efficient over long periods of use.

Superior Heat Dissipation

High-voltage systems generate significant amounts of heat, and effective thermal management is critical for preventing failures. A Heavy Copper PCB helps dissipate heat faster thanks to its large copper mass and enhanced conduction properties. This capability minimises hot spots and reduces the risk of thermal damage to surrounding components. Furthermore, better heat spreading allows for compact designs without sacrificing reliability or output power. Devices built with these boards can therefore operate longer, deliver consistent results, and remain reliable even in harsh environments.

Mechanical Strength and Durability

Heavy Copper PCBs are not only electrically robust but also mechanically stronger than traditional boards. Thick copper layers make the board less prone to warping, cracking, or delamination when exposed to physical stress. This extra durability is especially valuable in automotive, aerospace, and renewable energy applications where reliability is mission-critical. Equipment often faces vibration, extreme temperature swings, and environmental stress factors. With stronger PCBs in place, system integrity and operational performance remain intact, even under long-term and high-pressure use.

Compact and Efficient Design

Engineers can achieve more compact and efficient systems by adopting Heavy Copper PCB technology. With greater current-carrying capability, fewer board layers are required to achieve the same results. This simplifies layouts, reduces system size, and eliminates unnecessary complexity in power designs. Compact designs also help lower material and manufacturing costs while making installation easier and more convenient. At the same time, overall energy efficiency improves since electrical resistance losses are minimized. This combination results in a more cost-effective and performance-driven power solution.

Improved Reliability in Harsh Conditions

Industrial and energy systems often operate in environments that are far from ideal, demanding rugged design choices. Heavy Copper PCB structures are specifically built to withstand harsh conditions, including extreme temperatures, humidity, and electrical stress. They offer high resistance to corrosion, oxidation, and long-term mechanical fatigue. This reliability makes them suitable for use in wind turbines, solar power plants, and heavy-duty manufacturing machinery. By extending equipment lifetime and reducing repair needs, these boards cut maintenance costs and minimize expensive operational downtime.

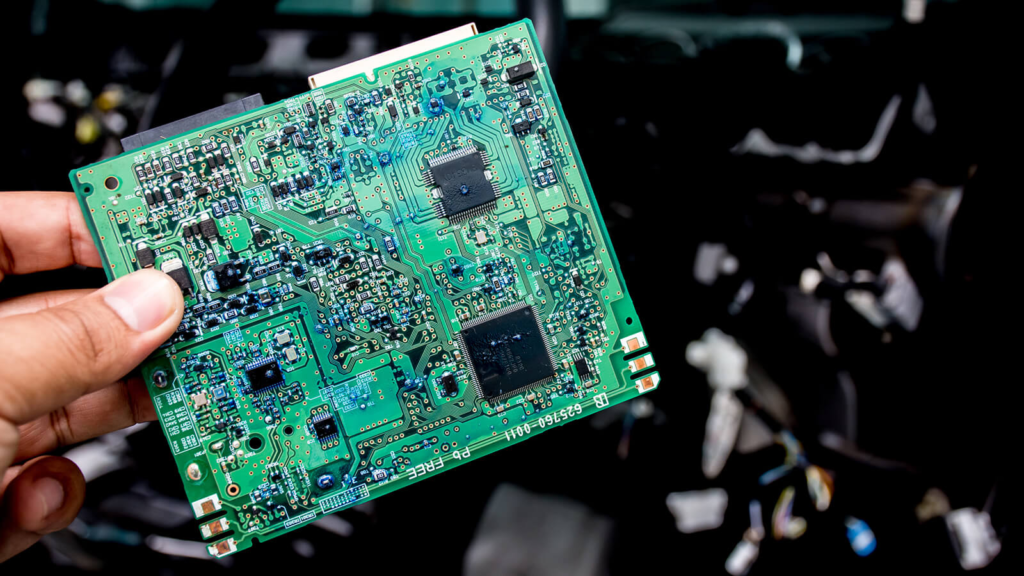

Versatility Across Applications

Heavy Copper PCBs are used in a wide variety of industries that depend on power reliability. Power distribution units, converters, and electric vehicles all rely on this technology for safe energy transfer. They are also critical in military and aerospace systems, where circuit board failure is not an option. Thanks to their adaptable design, these boards can be customized to meet unique electrical or structural requirements. Whether needed in compact consumer electronics or large-scale power modules, Heavy Copper PCB technology adjusts to different engineering challenges.

Heavy Copper PCB for Reliable High Voltage Power Distribution

A Heavy Copper PCB is essential for ensuring reliable high-voltage power distribution across multiple industries and applications. It provides superior current handling, excellent heat dissipation, and unmatched mechanical durability. At the same time, it supports compact designs, lowers costs, and improves overall system efficiency. These benefits allow engineers and manufacturers to design solutions that are safe, stable, and cost-effective in the long term. For modern high-voltage systems that demand uncompromised performance, nothing delivers more reliability than a Heavy Copper PCB.