thick copper PCB for Power Reliability Engineering

Thick copper PCB technology has become a critical pillar of Power Reliability Engineering as power systems are pushed harder than ever before. From EV fast-charging networks to industrial automation and renewable energy plants, modern electronics must deliver higher current, greater stability, and higher uptime in smaller, harsher environments. By combining heavy copper layers, optimized layouts, and robust construction, a High Reliability Power PCB built with thick copper ensures that heat, current, and mechanical stress never compromise long-term performance.

thick copper PCB as the Backbone of High Reliability Power PCB Design

Every reliable power system begins with a stable electrical foundation. A thick copper PCBs provide exactly that by using heavier copper layers to carry high current with lower resistance and far less heat generation. This creates a strong base for any High Reliability Power PCB. Lower resistance means less energy loss and fewer hot spots, both of which directly improve system reliability. When current flows smoothly and temperatures remain controlled, components age more slowly and fail less often. In power reliability engineering, this predictable behavior is what separates mission-critical electronics from standard consumer boards.

Thermal Stability in Power Reliability Engineering

Thermal stress is one of the main causes of electronic failure. A thick copper PCB addresses this challenge by spreading heat efficiently across large copper areas, keeping temperatures even and stable. This is essential for any High Reliability Power PCB operating under heavy electrical load. When heat builds up in small areas, it weakens solder joints, damages components, and reduces electrical performance. Thick copper layers act as built-in heat spreaders, removing heat from sensitive devices and maintaining a balanced thermal profile. In power reliability engineering, this stability allows systems to run continuously without performance drops or unexpected shutdowns.

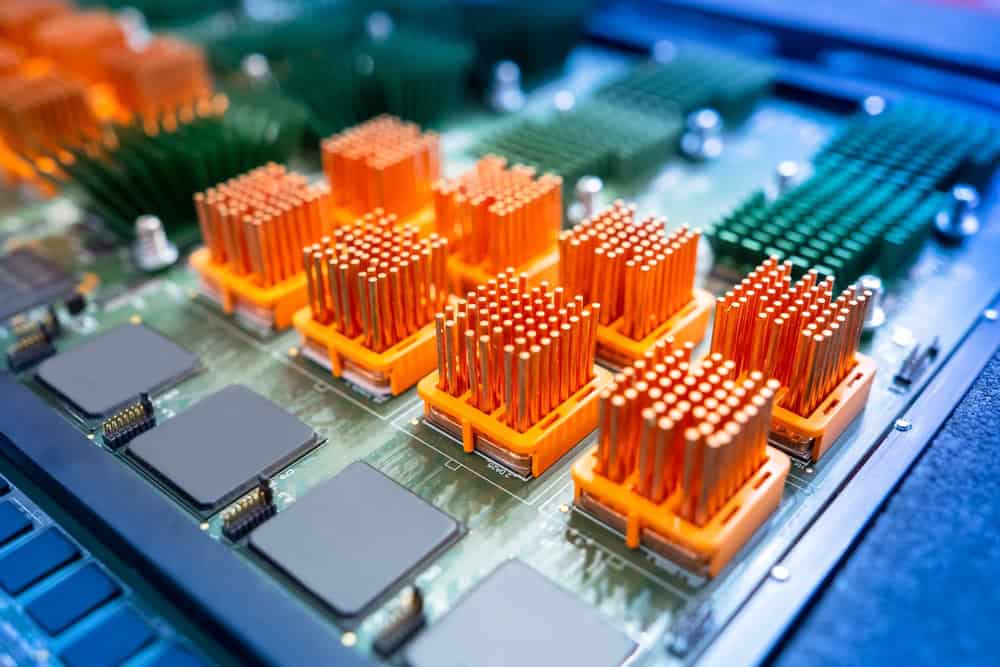

thick copper PCB for High-Current Power Applications

High current is unavoidable in modern power electronics. From battery management systems to motor drives and power converters, circuits must handle large electrical loads without degradation. A thick copper PCB is designed for exactly this task, making it the preferred choice for High Reliability Power PCB designs. Thicker copper traces and planes prevent overheating, reduce voltage drop, and improve overall electrical efficiency. This ensures that every part of the system receives clean, stable power, even when demand spikes. In power reliability engineering, this consistent electrical behavior protects both the PCB and the connected components.

thick copper PCB and Mechanical Strength for Long-Term Reliability

Reliability is not just electrical—it is also mechanical. Power electronics often operate in environments with vibration, thermal cycling, and physical stress. A thick copper PCB provides stronger interlayer adhesion and better resistance to cracking, which are crucial for a High Reliability Power PCB.

The heavier copper reinforces the board structure, helping it withstand repeated heating and cooling without delamination or trace damage. Over time, this mechanical stability translates into fewer failures, less maintenance, and longer product lifespans. For power reliability engineering, this kind of durability is just as important as electrical performance.

Performance in Harsh and Mission-Critical Environments

Many power systems operate under extreme conditions, including industrial plants, outdoor energy installations, and transportation systems. A thick copper PCB is built to perform in these demanding environments while maintaining High Reliability Power PCB standards. High humidity, wide temperature swings, and continuous electrical load all place stress on circuit boards. Thick copper technology helps mitigate these risks by improving heat dissipation, reducing electrical strain, and reinforcing board integrity. This makes thick copper designs ideal for applications where downtime is not an option.

Thick Copper PCB Manufacturing for Consistent Power Reliability

Even the best design fails without precise manufacturing. In a copper thickness, plating quality, and layer bonding must all meet strict tolerances to support High Reliability Power PCB performance. Advanced fabrication processes ensure that every trace carries current evenly and every thermal path works as intended. This consistency is vital for power reliability engineering, where small variations can lead to large differences in heat and electrical stress. High-quality thick copper boards deliver predictable, repeatable results across thousands of operating hours.

Why does a thick copper PCB define Power Reliability Engineering?

As power systems continue to grow in size, speed, and complexity, reliability becomes the ultimate design requirement. A thick copper PCB meets this challenge by combining superior current handling, advanced thermal control, and mechanical strength into a single platform for High Reliability Power PCB solutions. By reducing heat, minimizing electrical losses, and extending product life, thick copper technology enables engineers to design power systems that perform consistently under real-world conditions. For this reason, thick-copper PCBs for Power Reliability Engineering have become a cornerstone of modern high-power electronics.