The Future of Power Electronics: Heavy Copper PCB Role

Heavy Copper PCBs are becoming essential enablers as the demand for higher efficiency, performance, and reliability in power electronics grows at an unprecedented rate. These specialized printed circuit boards (PCBs) use thicker copper layers to meet the growing demands of high-current applications. They also improve thermal management and enhance mechanical stability. This article explores the vital role of High Current PCB in the future of power electronics. We’ll look at how their unique features are transforming industries like automotive, renewable energy, and industrial automation.

The Importance of Heavy Copper PCB in Power Electronics

Power electronics are essential for the efficient conversion, control, and conditioning of electrical energy. From solar inverters to electric vehicle (EV) powertrains, these systems require robust and efficient PCB solutions to handle high currents and manage thermal dissipation. Multi-layer PCBs play a significant role here, as their thick copper layers enable the PCB to carry higher electrical loads while maintaining stable performance. In addition, the enhanced thermal conductivity reduces the risk of overheating, improving the longevity and reliability of power electronics systems. These boards are indispensable in applications where traditional PCBs would struggle to manage the heat and power demands.

Enhancing Thermal Management with Heavy Copper PCB

Thermal management is one of the most pressing concerns in power electronics. As devices become smaller and more powerful, the ability to dissipate heat efficiently becomes crucial. Heavy Copper PCBs address this need by providing superior heat conduction through their thick copper traces. These PCBs help distribute heat more evenly across the circuit board, preventing localized overheating and ensuring that components remain within their optimal temperature ranges. In applications such as power supplies, inverters, and LED drivers, High-Copper PCBs significantly reduce the risk of component failure due to thermal stress, ensuring system stability and efficiency.

High Power Capacity of Copper-Rich PCB

One of the primary advantages of a is its ability to handle high electrical currents. The thicker copper layers in these PCBs enable them to handle high-power loads without overheating or damaging the circuit. This makes it ideal for high-current applications, such as power supplies, electric vehicles, and industrial equipment. The ability to carry high currents also translates to better performance and reliability in demanding applications, where lower-quality PCBs might fail under stress. As demand for high-power systems continues to grow, High-Copper PCBs will remain essential to ensuring system longevity and safety.

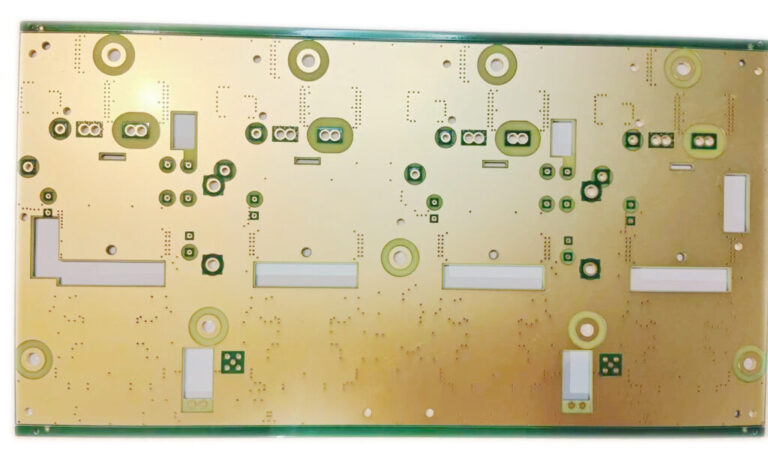

Enhanced Mechanical Strength for Industrial Applications

In addition to electrical and thermal performance, it also offers enhanced mechanical strength, making it suitable for use in harsh environments. Power electronics often operate in environments where temperature fluctuations, vibrations, and physical stress are common. They are built to withstand these challenges, ensuring that electronic components remain secure and functional even under extreme conditions. This durability is paramount in sectors like automotive, aerospace, and industrial automation, where reliability and performance are non-negotiable.

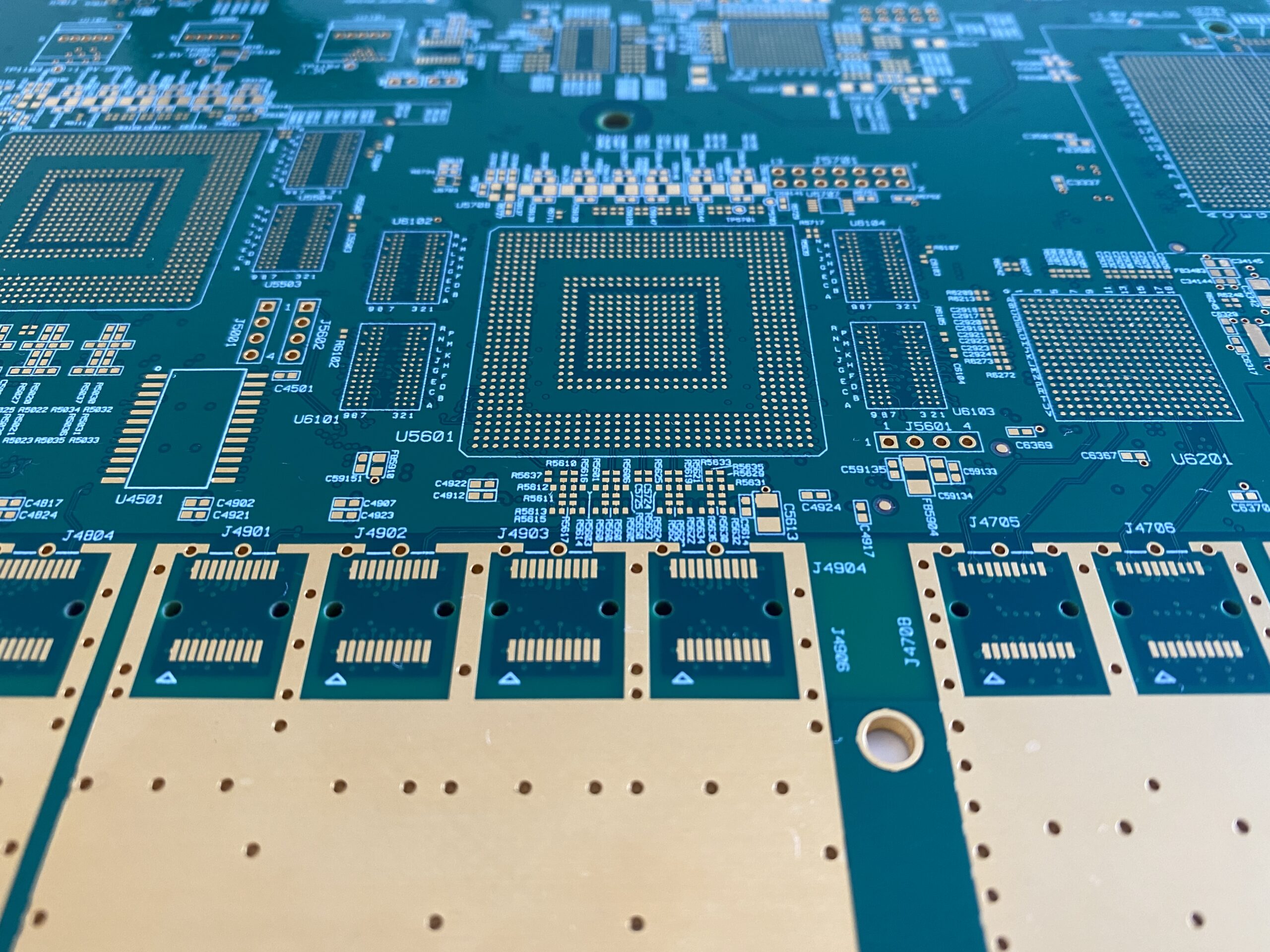

Advanced Multi-Layer PCB for Complex Circuits

As power electronics systems become more advanced, the need for complex circuit designs increases. High-Copper PCBs support multi-layer configurations, which are essential for creating intricate, high-performance circuit boards. These multi-layer boards enable more compact designs, reducing the overall system size while maintaining high power-handling and thermal management capabilities. The ability to stack multiple layers of copper enables engineers to design systems that are both more powerful and more efficient, a key factor in the development of next-generation power electronics.

The Future Outlook for High-Copper PCB in Power Electronics

The future of power electronics is closely linked to innovations in PCB technology. Multi-layer PCBs will remain central to this evolution. As power demands rise across industries such as electric vehicles, renewable energy, and industrial automation, the need for high-performance PCBs will grow. Advances in Multi-Layer PCB manufacturing, such as improved copper plating and precision etching, will boost their performance. These innovations will lead to more efficient designs. With the ongoing push for sustainable, energy-efficient solutions, it is poised to become a cornerstone of next-generation power electronics.