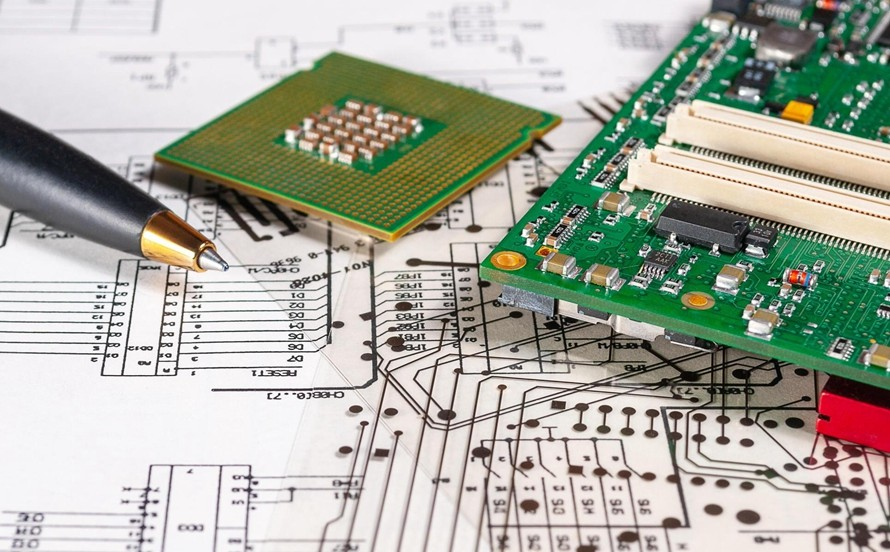

Why High Layer Count Set-top Box PCB Are Gaining Popularity in IPTV Devices?

The growing demand for IPTV and digital broadcasting is driving innovation in hardware, particularly in the area of printed circuit boards. Multilayer set-top box PCBs enable more complex routing, better signal integrity, and improved thermal management. As IPTV services expand, hardware must meet performance requirements. Additionally, the trend toward more minor, thinner devices requires that internal components be packed more densely. Multilayer boards enable manufacturers to integrate more functionality without increasing board size. As a result, set-top box PCB configurations are evolving into more advanced, compact solutions that are ideal for modern IPTV environments.

The Importance of Signal Integrity and Data Handling

Signal integrity is critical in delivering uninterrupted IPTV streams. High-layer-count Set-top Box PCBs improve signal paths by allowing separate layers for power, ground, and signal routing. This separation minimizes interference and crosstalk, ensuring a stable video and audio output.

Additionally, IPTV devices need to handle large data volumes with low latency. Multilayer PCBs support high-speed components, such as processors and memory chips. These layers act as highways for data, maintaining throughput and reducing processing delays. With improved layout and ground shielding, these boards significantly elevate performance in streaming applications.

Power Distribution and Heat Management in IPTV Devices

IPTV set-top boxes often include processors, tuners, and Wi-Fi modules. These components generate heat and require efficient power delivery. A high-layer-count Set-top Box PCB allows for better thermal management by distributing heat across inner copper layers and utilizing via structures to transfer heat away.

At the same time, these boards can incorporate power planes and ground planes on separate layers, resulting in a more stable power distribution. This design reduces voltage drops and electromagnetic interference. As IPTV devices become more powerful, the importance of thermal and power efficiency grows, making multilayer PCBs indispensable.

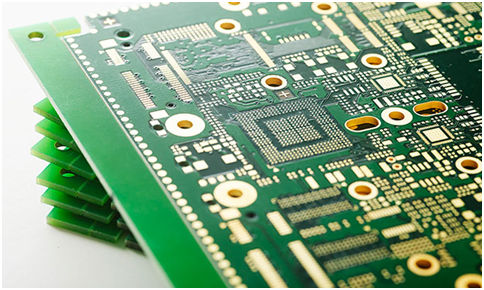

Enabling Compact Designs Without Sacrificing Performance

Modern consumers seek IPTV boxes that are compact and visually appealing. However, shrinking the form factor must not compromise performance. A high-layer count Set-top Box PCB makes it possible to pack advanced features into compact units. More layers mean more routing options, allowing designers to avoid signal congestion.

These compact PCBs support tighter integration of components such as decoders, Ethernet controllers, and Bluetooth modules. With a well-structured layer stack, manufacturers achieve both form and function. This balance is crucial in the consumer electronics industry, where user expectations for both design and performance are exceptionally high.

Supporting Multiple Functions and Interfaces

Today’s IPTV boxes are more than just video receivers. They support internet browsing, gaming, voice control, and smart home integration. high-layer-count Set-top Box PCBs enable the addition of multiple interfaces, such as HDMI, USB, and optical audio, without compromising board integrity.

Multiple layers allow for strategic routing of data and power signals to support these functions. Isolation layers also prevent signal leakage between sensitive components. This complexity would be difficult to achieve on a two- or four-layer board. Thus, multilayer PCBs are crucial to expanding the functionality of IPTV hardware.

Improving Manufacturing Efficiency and Yield

High-layer-count PCBs sound complex, but they can streamline production. Advanced Set-top Box PCB designs incorporate manufacturing-friendly layouts that reduce defects and improve yield rates. Manufacturers use controlled impedance, blind vias, and buried vias to optimize space and simplify assembly.

In high-volume production environments, efficiency is key. Well-planned layer stacking can lower the number of reworks and improve quality control outcomes. As more companies invest in IPTV hardware, reliable mass production becomes a priority. That makes multilayer PCB design not just beneficial but essential.

Cost Versus Performance Trade-Offs

There is no denying that high-layer count Set-top Box PCBs are more expensive than simpler alternatives. However, the benefits often outweigh the initial costs. Enhanced performance, improved reliability, and extended product life result in reduced maintenance and fewer returns.

Additionally, compact and efficient boards lower enclosure costs and shipping fees. For manufacturers, this can balance out the investment. The shift in the market indicates that buyers are willing to pay more for smoother performance and technology that is future-ready.

Why High Layer Count Set-top Box PCBs Are Gaining Popularity in IPTV Devices

The IPTV market is evolving towards more advanced features, faster data processing speeds, and smaller device footprints. High-layer set-top box PCBs can effectively meet these requirements, providing comprehensive solutions to modern hardware challenges, whether it is signal integrity or thermal management.