When to Choose Double-sided PCB Over Multilayer Boards for Cost Efficiency?

Printed circuit boards are the backbone of the electronics industry. Choosing between a double-sided PCB and a multilayer board can directly influence both cost and performance. In many cases, companies find that using a double-sided PCB strikes a balance between reliability and affordability, especially when design complexity does not require advanced stack-ups. Let’s dive into when this choice makes the most sense.

Understanding the Basics of Double-sided PCB

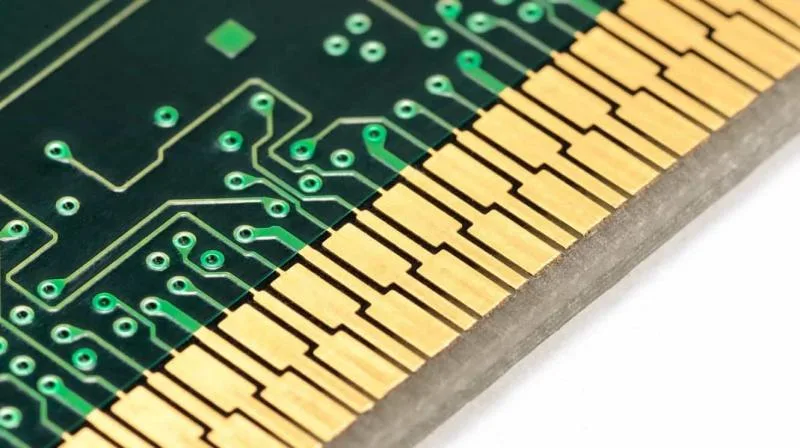

A double-sided PCB has copper traces on both sides of the substrate. Designers use vias to connect circuits between layers, which doubles routing space compared to single-layer designs. This configuration offers flexibility without the complexity of multilayer boards. According to IPC standards, double-sided boards are the dominant choice in consumer and industrial electronics due to their balance of cost and functionality. Their simpler design also speeds up prototyping, reducing time to market for many applications that do not require high-density interconnects.

Comparing Cost Structures with Multilayer Boards

Cost is a crucial factor in selecting a PCB. A double-sided PCB typically requires fewer lamination cycles, resulting in reduced manufacturing time and expenses. In contrast, multilayer boards involve complex stacking, higher material costs, and more inspection steps. Market data from Prismark (2023) shows that multilayer PCB fabrication can cost 2–3 times more than a double-sided alternative, depending on layer count and reliability requirements. Companies producing mid-volume devices often favour double-sided designs to maximise cost efficiency while avoiding over-engineering.

When Functionality Meets Affordability

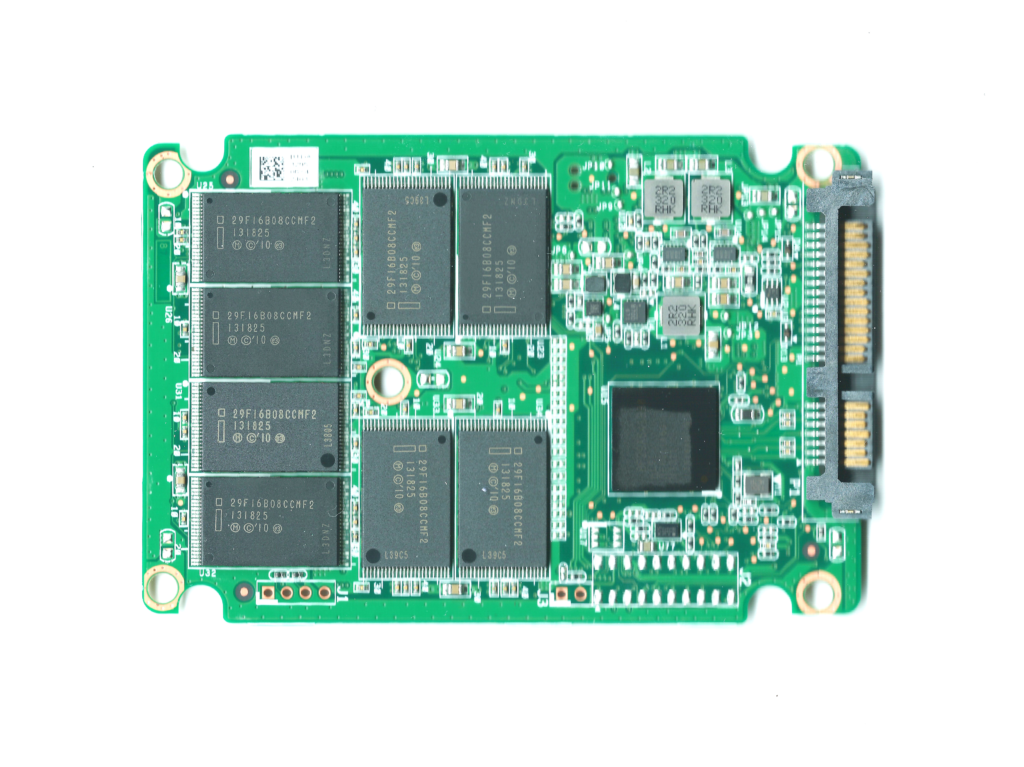

Double-sided PCBs are well-suited for applications that require moderate routing density. Power supplies, LED lighting systems, and automotive modules often rely on them because they provide sufficient signal paths without incurring extra costs. Engineers can integrate analogue and digital sections effectively while maintaining straightforward assembly. While multilayer boards offer tighter signal integrity, many devices do not need that level of sophistication. Choosing a double-sided PCB ensures optimal performance while keeping project budgets under control.

Thermal and Mechanical Considerations

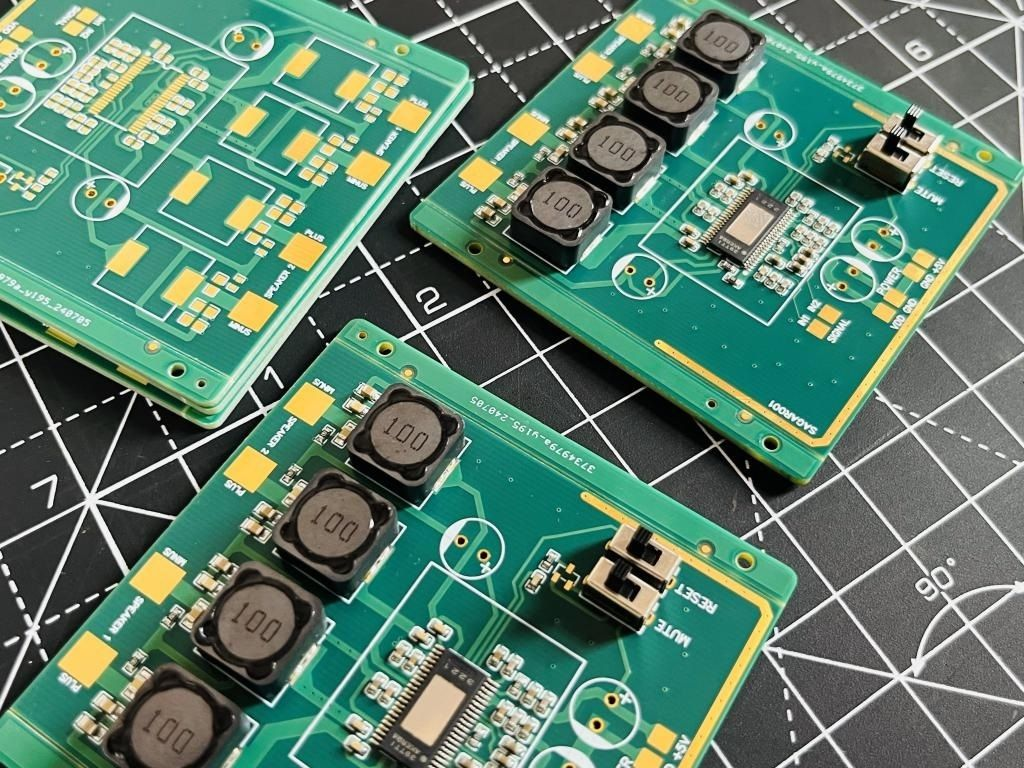

Heat management is a key factor in PCB reliability. Double-sided PCBs enable components to be placed on both sides, improving airflow and reducing the occurrence of hotspots. For industrial devices operating in harsh environments, this feature helps extend product lifespan. Multilayer boards, although more advanced, can trap heat within their inner layers, making cooling more challenging. Case studies from automotive electronics demonstrate that double-sided PCB layouts provide reliable thermal performance in control units, eliminating the need for the added expense of multilayer design.

Design Complexity and Manufacturability

Simplicity often brings efficiency. Double-sided PCBs are easier to design, simulate, and manufacture compared to multilayer boards. Fabrication processes involve standard drilling and plating, which reduces the risk of defects. This also means higher yields in production, resulting in a lower overall cost per unit. For small and medium enterprises, this factor plays a significant role in scaling production. By contrast, multilayer designs often require advanced CAD tools and extended testing cycles, which significantly increase engineering costs.

Industry Use Cases Favouring Double-sided PCB

Many industries continue to rely on double-sided boards for mainstream products. Consumer electronics such as televisions, printers, and audio systems use them extensively. In automotive electronics, control modules and lighting systems depend on their durability and affordability. Even in telecommunications, routers and power regulators often operate reliably on double-sided layouts. These real-world applications demonstrate that engineers choose double-sided PCB solutions when performance and cost efficiency align.

Future Outlook for PCB Selection

While multilayer boards are essential for high-frequency and high-density applications such as 5G and advanced computing, double-sided PCBs remain relevant. Analysts from Technavio (2024) predict that demand for double-sided boards will continue to grow steadily, particularly in cost-sensitive markets such as consumer appliances and energy systems. With manufacturing processes becoming more efficient, the gap between double-sided and multilayer solutions will remain significant, making the former an attractive option for many OEMs.

Conclusion on Double-sided PCB

Selecting the right PCB depends on balancing cost, functionality, and design complexity. Double-sided PCBs provide an affordable yet reliable choice for a wide range of applications. They help companies control manufacturing expenses, maintain design flexibility, and achieve efficient production. For projects that do not require the advanced routing density of multilayer boards, opting for a double-sided PCB delivers the best mix of performance and cost efficiency.