How to Prevent Wear and Oxidation on Edge Connectors Over Time

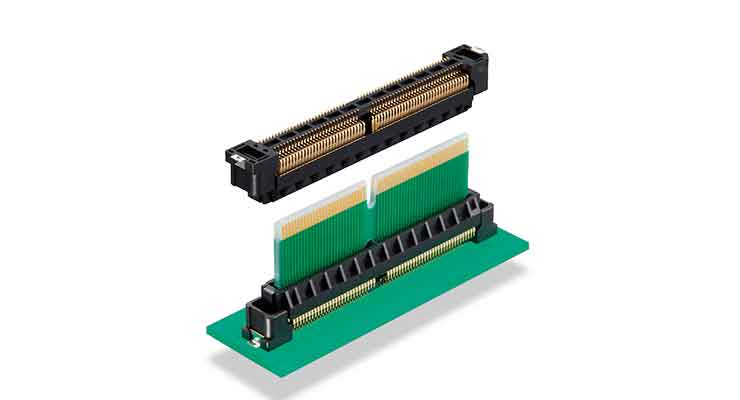

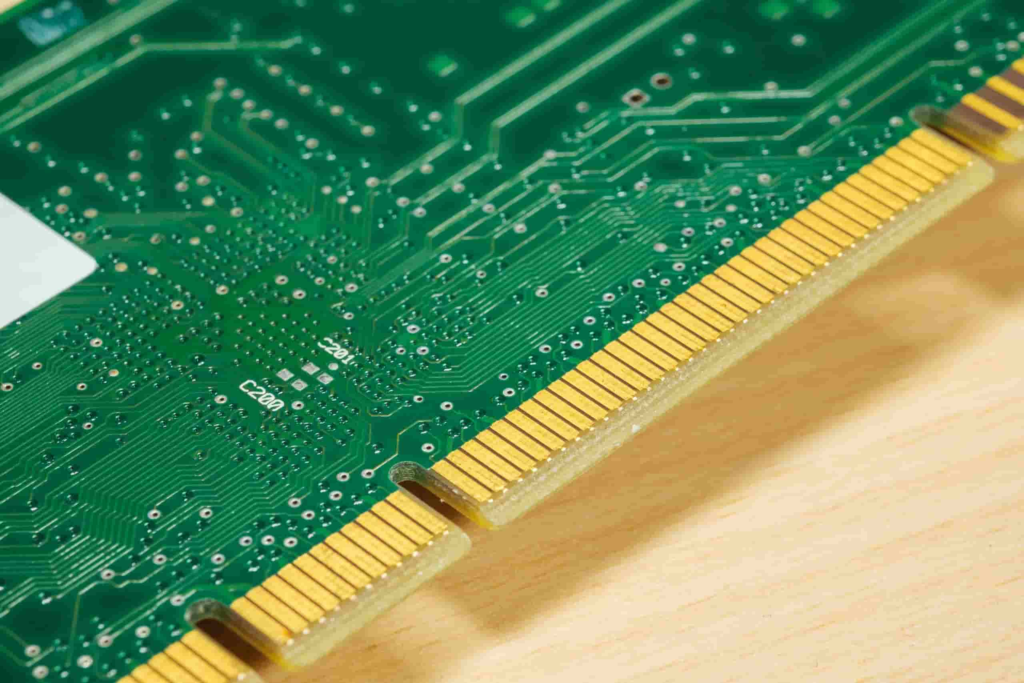

Edge Connectors play a pivotal role in electrical connectivity for a wide range of devices, especially in high-performance gold finger PCBs. These connectors are exposed to repeated insertions, environmental contaminants, and temperature fluctuations. Over time, these factors can lead to physical wear and oxidation, which in turn impact conductivity and signal integrity.

Choosing the Right Materials for Durability

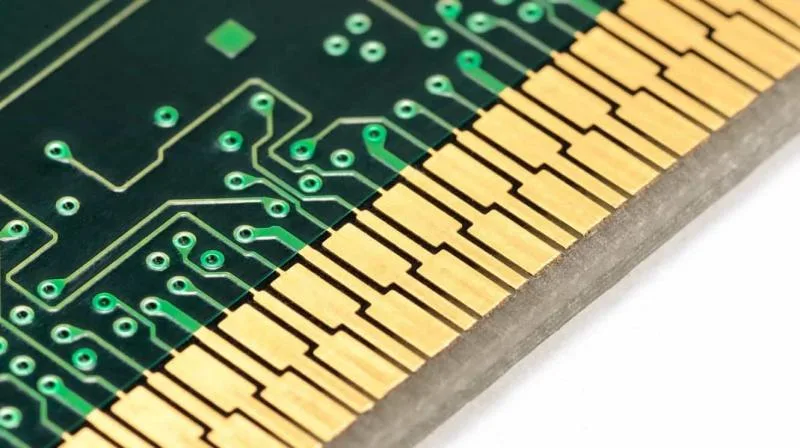

One effective way to extend the life of Edge Connectors is by selecting high-quality materials. Gold plating, especially on gold finger PCBs, offers excellent corrosion resistance while maintaining conductivity. However, the thickness of the plating and the underlying materials also play a role.

Continually evaluate the trade-offs between cost and performance. For instance, thicker gold layers last longer but are more expensive. Alternatively, using nickel underlayers can improve adhesion and mechanical strength, reducing the risk of delamination or cracking during repeated use.

Implementing Proper Cleaning and Handling Protocols

Even the best Edge Connectors can fail prematurely without appropriate maintenance. Regular cleaning removes dust, oils, and oxidation that can interfere with electrical contact. Use isopropyl alcohol and lint-free swabs for gentle, non-abrasive cleaning.

Handling also plays a key role. Always wear gloves when working with PCBs to prevent skin oils from contaminating contact surfaces. Store PCBs in anti-static, dust-free environments to preserve connector integrity during storage or transport.

Environmental Sealing and Conformal Coating

To combat oxidation, environmental protection is critical. Conformal coatings provide a barrier against moisture, dust, and chemicals. These coatings are especially beneficial in industrial or outdoor settings where Edge Connectors are more exposed.

Additionally, using enclosures with proper IP ratings can prevent ingress of air and humidity. For gold finger PCB assemblies, pairing these physical protections with internal monitoring systems can significantly improve long-term reliability.

Minimizing Insertion Cycles and Mechanical Stress

Repeated mating cycles accelerate wear. Where possible, limit the number of times a connector is engaged or disengaged. Design systems with fixed connectors or consider using replaceable interface modules.

Reduce mechanical stress by ensuring proper alignment during insertion. Misalignment causes scratching and uneven pressure, which wears down the contact points. Using guide rails or insertion tools can help minimize these risks effectively.

Applying Lubricants and Anti-Oxidation Compounds

Specialized lubricants and anti-oxidation compounds can reduce wear and protect contact surfaces. These compounds fill microscopic gaps, blocking air and moisture while improving electrical performance.

Ensure that you select products compatible with gold finger PCB and other sensitive electronic components. Regularly reapply as part of scheduled maintenance. This simple yet effective practice can significantly extend the operational life of Edge Connectors.

Designing for Serviceability and Redundancy

If a system relies heavily on Edge Connectors, consider designing for easy servicing. Modular designs enable the quick replacement of worn parts without requiring the dismantling of the entire assembly. This approach reduces downtime and prolongs system life.

Also, consider incorporating redundancy in critical circuits. Dual-path connections ensure continuity even if one connector degrades. This method is commonly used in aerospace and medical electronics, where failure is not an option.

Long-Term Reliability Starts with Smart Planning for Edge Connectors

Preventing wear and oxidation on Edge Connectors isn’t just about maintenance—it begins at the design phase. Select materials carefully, adhere to best practices for handling, and safeguard components with suitable coatings and enclosures. Leverage proven strategies like using gold finger PCB layouts, insertion guides, and redundant connections. By addressing the issue from multiple angles, engineers and manufacturers can ensure stable, long-lasting performance in high-reliability applications. Ultimately, proactive planning consistently outperforms reactive repairs in preserving Edge Connectors.