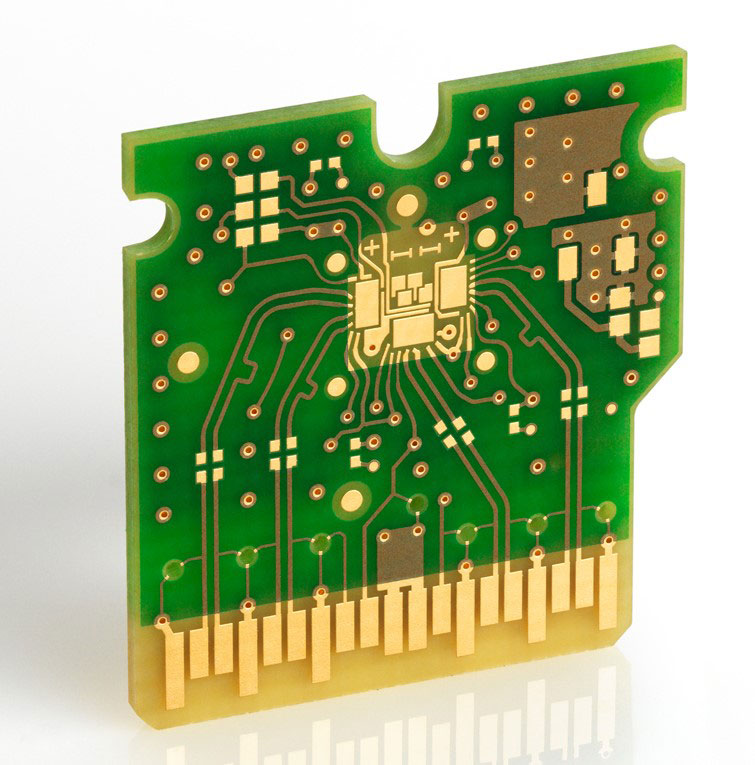

How to Inspect and Maintain Gold Finger PCB Connectors?

Gold Finger PCB connectors are essential components for reliable electronic performance. They provide durable, low-resistance connections between printed circuit boards and devices. However, repeated insertion, environmental exposure, and improper handling can cause wear, corrosion, or contamination. Proper inspection and maintenance prevent failure, extend service life, and maintain signal integrity. Understanding these best practices helps engineers and technicians ensure consistent operation while avoiding costly downtime and repairs.

Visual Inspection for Wear and Damage

Begin with a detailed visual inspection of Gold Finger PCB connectors. Carefully examine each contact for scratches, discolouration, corrosion, or pitting. Check for signs of bending, misalignment, or uneven surfaces. Use magnifying tools or inspection microscopes for small pins. Pay special attention to edges that frequently mate with sockets. Document any visible damage. Early detection of wear prevents further deterioration and potential electrical failures. Regular visual inspections form the foundation of proper Gold Finger PCB maintenance.

Cleaning Contaminated Contacts

Over time, dust, oils, flux residues, or oxidation can degrade Edge Connector PCB connections. Use a lint-free cloth, specialised swabs, or anti-static brushes to clean surfaces. Isopropyl alcohol or approved PCB cleaners effectively remove contaminants without harming gold plating. Avoid abrasive tools or aggressive solvents that can scratch or erode contacts. Clean all exposed pins thoroughly, ensuring residues are fully removed. Routine cleaning maintains conductivity, reduces signal errors, and prolongs connector life. Consistent cleaning is a critical step in Edge Connector PCB care.

Testing Electrical Continuity

After cleaning, test electrical continuity for all connector pins. Use a calibrated multimeter or dedicated PCB tester. Measure resistance across contacts and compare to manufacturer specifications. Look for high resistance, open circuits, or intermittent connections. Identifying electrical anomalies early allows timely repair or replacement. Perform tests periodically, especially for high-use or mission-critical boards. Regular electrical testing ensures consistent, reliable performance of Gold Finger PCB connectors.

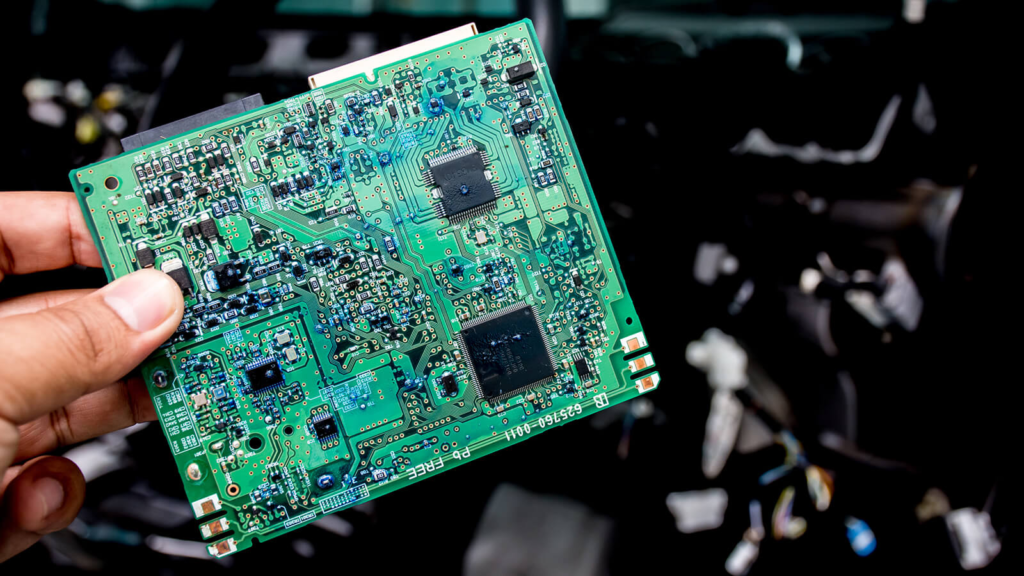

Proper Handling Techniques

Proper handling significantly affects the connector’s lifespan. Always hold PCBs by the edges, avoiding direct contact with gold fingers. Avoid dropping or flexing boards, as this can cause them to bend or misalign connectors. Protect connectors from static discharge using grounding straps, anti-static mats, or protective bags. Handling with care reduces wear, contamination, and risk of damage. Consistent adherence to handling protocols supports long-term reliability and reduces costly maintenance of the Gold Finger PCB.

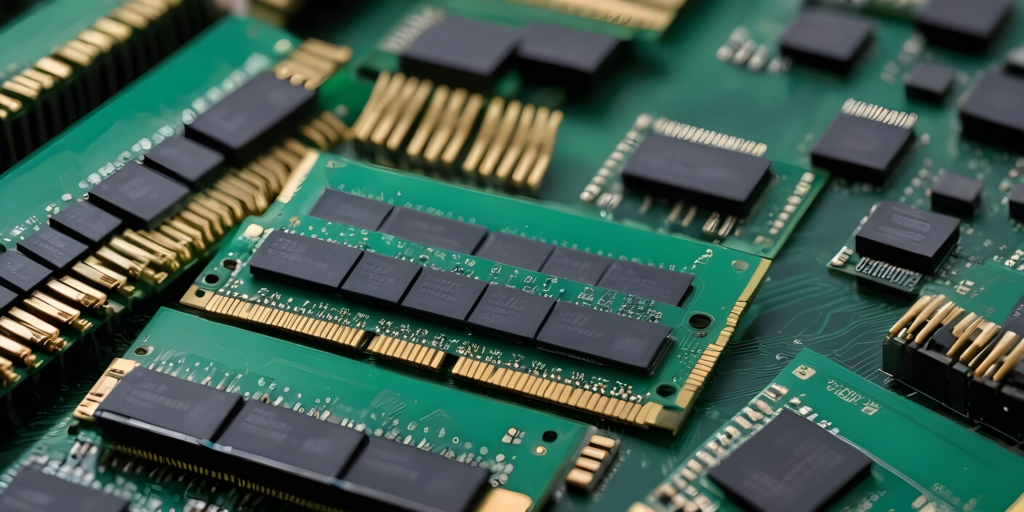

Insertion and Removal Practices

Insertion and removal cycles contribute to mechanical wear over time. Always align PCBs correctly with mating sockets. Apply even, steady pressure; do not force connections. Avoid repeated unnecessary insertions. For connectors in high-cycle applications, consider using guides or fixtures to reduce mechanical stress. Proper insertion and removal techniques preserve contact integrity, maintain signal quality, and extend connector service life. Safe handling practices are essential for reliable Gold Finger PCB operation.

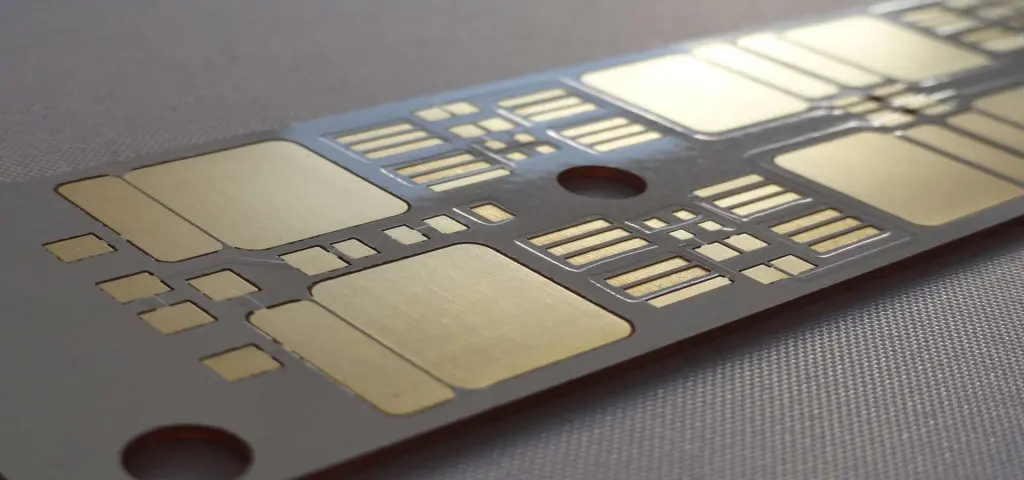

Lubrication and Protective Coatings

In some industrial or high-use applications, thin protective coatings or specialised conductive lubricants may be beneficial. They reduce friction, prevent oxidation, and enhance connector durability. Only use materials approved for electronics; excessive lubrication can attract dust and reduce performance. Apply coatings sparingly and evenly across all mating surfaces. Properly applied protection increases service life while maintaining optimal electrical performance. Lubrication and coatings are an optional yet effective method for maintaining the Gold Finger PCB connectors.

Regular Maintenance Schedule

Establishing a regular maintenance schedule ensures long-term reliability. Frequency depends on usage intensity, environmental exposure, and connector criticality. High-vibration or industrial applications require more frequent inspections: document visual checks, cleaning, electrical testing, and any repairs or replacements. Tracking maintenance helps identify patterns of wear and potential issues before they affect operation. A structured schedule supports proactive maintenance and maximises the longevity of Gold Finger PCB connectors.

Comprehensive Inspection and Maintenance of Gold Finger PCB

The proper care of Gold Finger PCB connectors involves thorough visual inspections, cleaning, electrical testing, careful handling, controlled insertion, optional protective coatings, and a consistent maintenance schedule. Following these practices prevents physical damage, contamination, and electrical failure. Proactive maintenance ensures long-term reliability, maintains signal integrity, and reduces costly downtime. By combining these methods, engineers can protect Gold Finger PCB connectors and enhance overall system performance. Comprehensive inspection and maintenance strategies are vital for the optimal operation of every Gold Finger PCB in use.