How PARYLENE Nano Vacuum Coating improves electronics reliability in harsh environments?

Parylene Nano Vacuum Coating provides electronics with a thin, uniform barrier that helps assemblies withstand harsh environments. In many field cases, even minor defects can cause early failures. Therefore, engineers use this coating to block moisture, contaminants, and corrosion. Moreover, it conforms to complex geometries without adding bulk. As a result, teams protect sensitive circuits without major redesign. This article explains practical benefits, process basics, and how to qualify the coating for production. Additionally, it highlights the tests and controls that are most important.

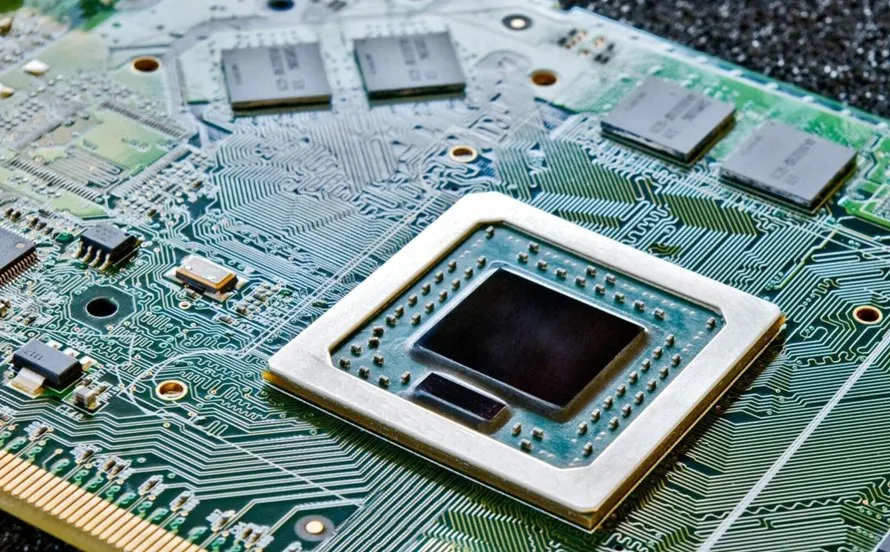

Conformal coverage and material basics

PARYLENE Nano Vacuum Coating deposits as a true molecular film. Consequently, it follows uniform traces, vias, and small gaps. Additionally, it forms pinhole-free layers that prevent localized corrosion. Additionally, the film adds minimal thickness, ensuring clearances remain intact. Therefore, designers keep part geometry while gaining a barrier. Moreover, the coating offers low gas and moisture permeability. Thus, sensitive components gain protection without the need for bulky potting. Finally, you retain signal paths and mechanical fits.

Moisture and corrosion resistance

Moisture drives many field failures, so mitigating this issue matters. Parylene Nano Vacuum Coating effectively blocks water and ionic contaminants. As a result, galvanic corrosion and dendritic growth drop significantly. Additionally, the coating protects metal from salty or acidic atmospheres. Therefore, connectors, traces, and exposed pads stay functional longer. Additionally, you can coat the assembled boards to protect the sensors and contacts. Consequently, products last longer in coastal, automotive, and outdoor applications.

Electrical insulation and signal stability

Parylene Nano Vacuum Coating provides reliable dielectric properties across a wide range of temperatures. Thus, it prevents surface leakage and short circuits in humid conditions. Moreover, it maintains consistent capacitance at thin-film thicknesses. Consequently, high-frequency and analog circuits remain stable. Also, the coating resists tracking and corona in aggressive environments. Therefore, teams often choose it over bulky potting to preserve signal integrity. Additionally, it reduces weight and maintains thermal paths for effective heat dissipation.

Mechanical protection and handling durability

Although thin, PARYLENE Nano Vacuum Coating adds mechanical resilience. It reduces micro-abrasion and limits micro-crack formation. Also, it remains flexible during thermal cycling and bending. Therefore, wire bonds and solder joints receive additional protection during handling and transportation. Moreover, the coating improves adhesion for secondary finishes and reduces particle shedding. Consequently, assemblies survive shipping and field stresses better than uncoated units. Finally, you lower the mechanical damage during assembly operations.

Thermal and chemical resistance

Electronics are exposed to temperature fluctuations and solvents during their life cycles. Parylene Nano Vacuum Coating is compatible with a wide range of temperatures and many common cleaning solvents. As a result, it retains barrier performance after repeated thermal cycles. In addition, it resists common fuels, lubricants, and cleaning agents. Therefore, coatings protect against corrosion even after the manufacturing process is complete. Also, selective rework remains possible if you plan to mask and controlled removal. Consequently, the coating is suitable for both production and service stages.

Deposition workflow and production integration

The vacuum process vaporizes a dimer and polymerizes it on the parts. First, load assemblies into a vacuum chamber. Next, mask connectors and optical windows as required. Additionally, the process eliminates surface-tension issues associated with liquid coatings. Therefore, coverage is uniform on complex parts.

Additionally, you can control thickness precisely for repeatability. Thus, production teams integrate PARYLENE Nano Vacuum Coating with modest fixture and QA changes. Finally, scale-up needs vendor qualification and clear acceptance tests.

Testing, masking, and rework strategy

Validate coatings with salt spray, thermal cycling, and humidity tests before ramp. Also, define clear masking for connectors, sensors, and moving parts. Additionally, establish rework rules: selective stripping or mechanical removal is only permitted where allowed. Therefore, acceptance criteria must include adhesion, coverage, and electrical checks. Moreover, require sample runs from coaters and review vendor data. Consequently, a well-defined test plan reduces surprises and warranty risk. Finally, include coating steps in product qualification documents.

Recommendations and next steps — PARYLENE Nano Vacuum Coating

Adopt PARYLENE Nano Vacuum Coating when moisture, corrosion, or space make potting impractical. First, run prototype batches and test salt spray and thermal cycles. Then, define masking, rework, and inspection criteria with your coater. Also, it requires incoming inspection and vendor traceability. Next, integrate coating steps into qualification and maintenance plans. Finally, choose qualified coaters and monitor KPIs for field returns and claims. By doing so, you extend field life, cut warranty costs, and keep performance in harsh environments.