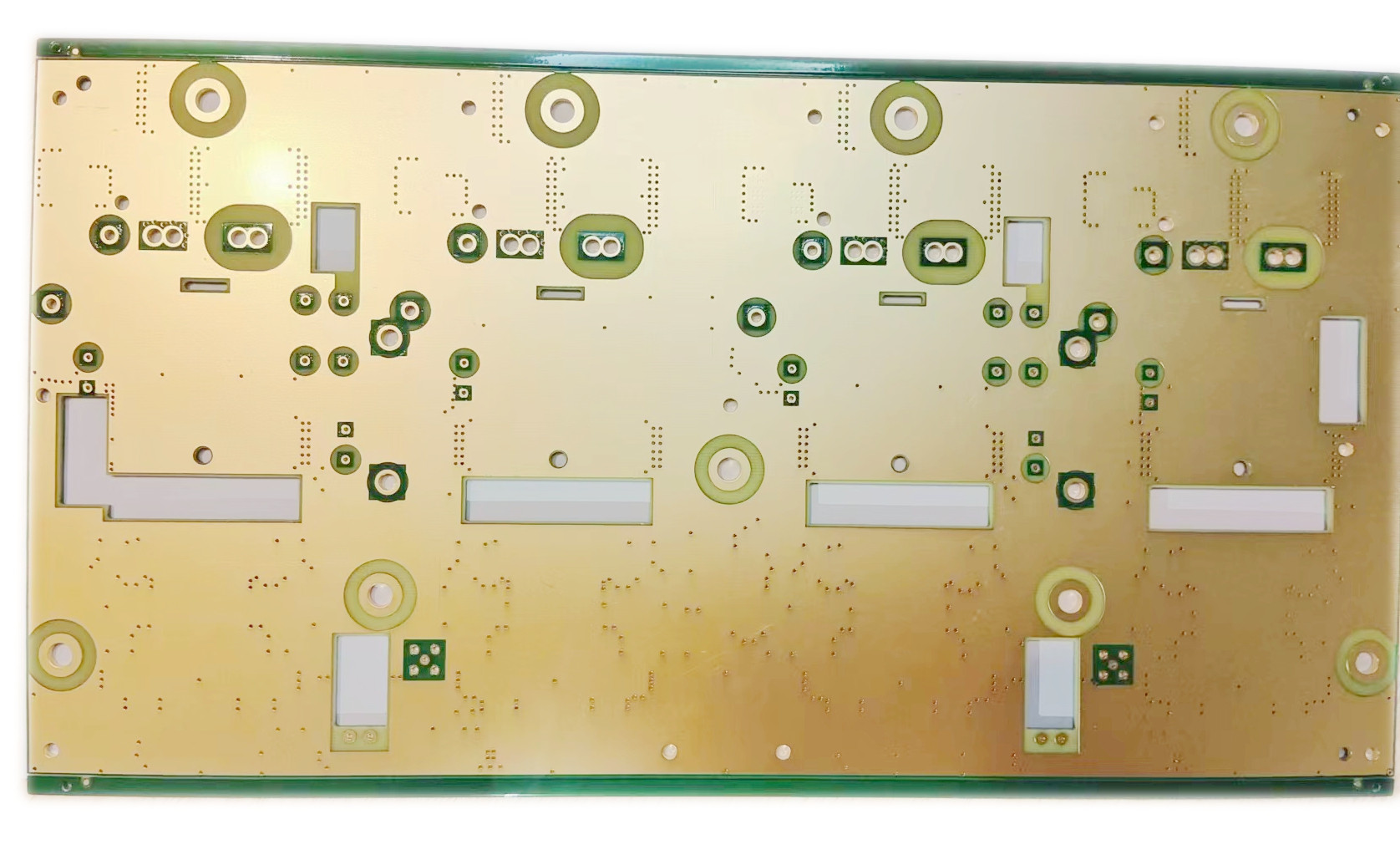

How Heavy Copper PCB Reduces Failure Risks in Power Supply Modules?

The Heavy copper PCB plays a vital role in reducing failure risks within power supply modules. These specialised printed circuit boards utilise thick copper layers to safely and efficiently handle high current loads. They serve as the backbone of many high-power electronic systems. Without the proper PCB design, power supply modules face increased risks of overheating, electrical failure, and even catastrophic breakdowns.

Enhanced Current-Carrying Capacity

One of the standout advantages of heavy copper PCBs is their ability to handle high currents with ease. Thicker copper layers increase the board’s current-carrying capacity, preventing excessive heat buildup during operation. This minimizes the likelihood of conductor degradation or circuit failure.

Additionally, these boards enable more compact designs by reducing the need for oversized traces or extra layers. The enhanced current flow ensures stable performance under heavy loads, making Heavy Copper PCB ideal for power-hungry systems. Therefore, current capacity is a core reason why these PCBs reduce failure risks in demanding applications.

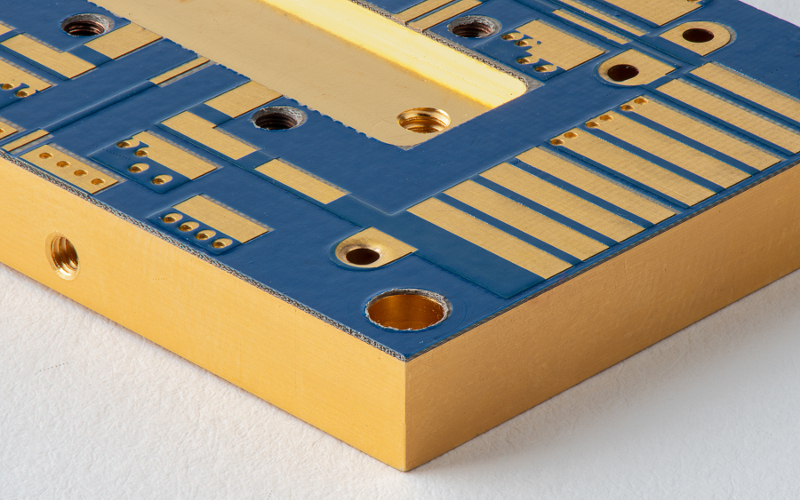

Superior Thermal Management Reduces Heat-Related Failures

Heat is a significant contributor to failure in power supply modules. Heavy copper PCBs excel at dissipating heat due to their thick copper layers. The improved thermal conductivity allows heat to spread more evenly, preventing localized hotspots that can damage components.

Furthermore, integrating heavy copper into the PCB design reduces reliance on external cooling systems. Designers often combine thermal vias and copper planes for even greater heat dissipation. These strategies result in lower operating temperatures, enhancing overall system reliability and protecting sensitive parts from thermal stress.

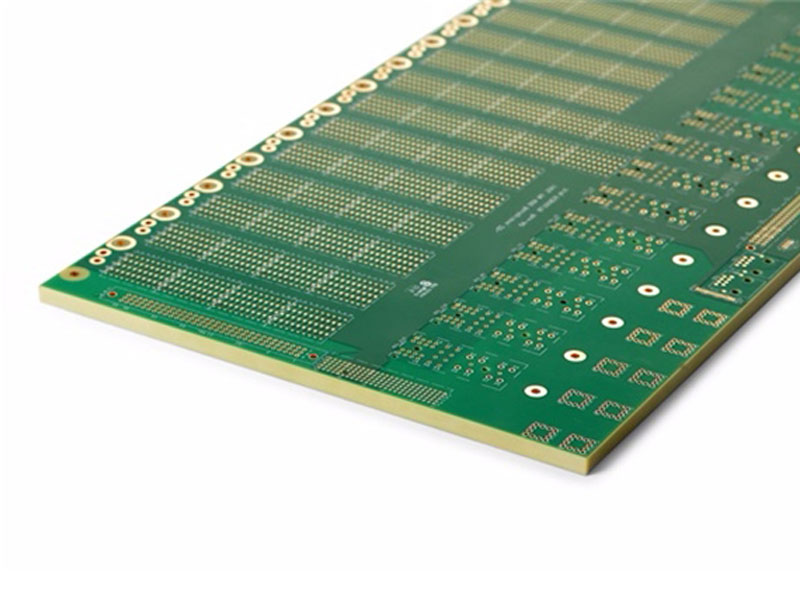

Mechanical Strength for Harsh Environments

Heavy copper PCBs provide enhanced mechanical durability, making them suitable for use in harsh environments. The additional copper thickness reinforces the PCB structure, enabling it to withstand vibration, shock, and mechanical stress. This reduces the likelihood of cracks or fractures during both manufacturing and operation.

Moreover, the improved robustness makes these PCBs ideal for automotive, aerospace, and industrial applications. Even under continuous mechanical strain, heavy copper PCBs maintain their structural integrity. As a result, its mechanical resilience plays a crucial role in reducing failure rates in harsh conditions.

Extended Product Lifespan Through Reliability

By combining electrical and thermal advantages, heavy copper PCBs significantly extend the lifespan of power supply modules. Stable current flow and effective heat dissipation reduce stress on all circuit components, resulting in a longer operational life.

Additionally, fewer component replacements and maintenance requirements translate into cost savings over time. This longevity makes Heavy Copper PCB an attractive choice for mission-critical systems. Ultimately, these reliability improvements protect both the device and the user from unexpected failures.

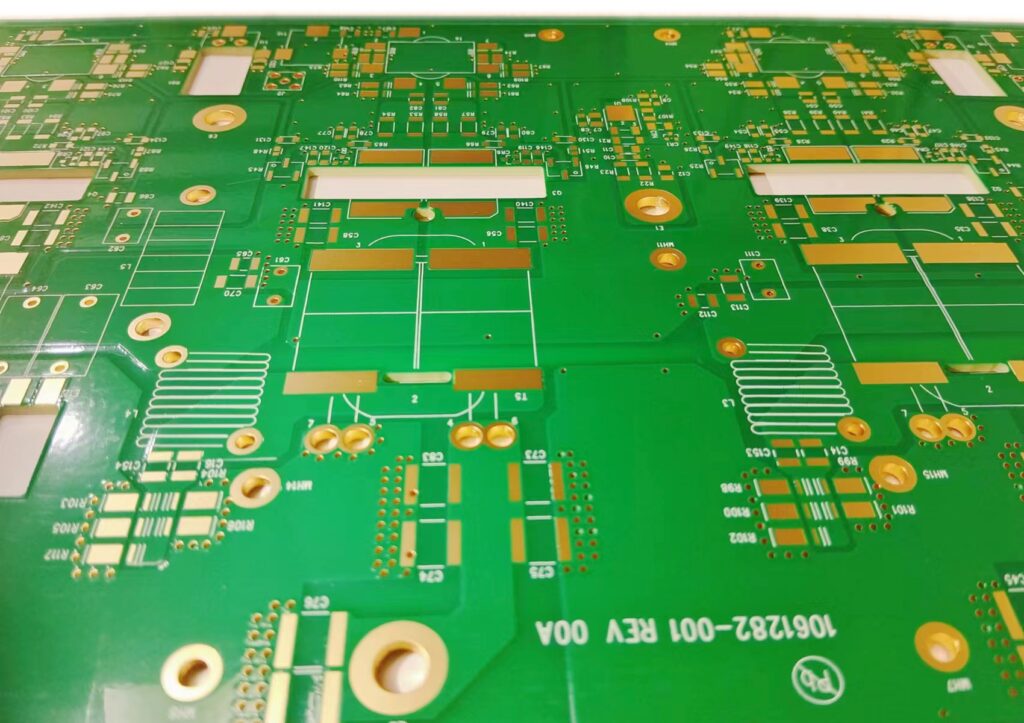

Design Flexibility for Custom Power Applications

Heavy Copper PCB provides exceptional design flexibility for engineers working on custom power supply solutions. Its ability to handle high current in compact areas allows more efficient circuit layouts, even in space-constrained designs.

Furthermore, these PCBs can integrate complex multilayer architectures with both high-power and control circuits on the same board. This reduces assembly time and simplifies production. Therefore, design flexibility is another factor that makes Heavy Copper PCB highly effective in minimizing failure risks in specialised applications.

Cost Efficiency Through Durability

Although heavy copper PCBs involve higher initial costs, their long-term economic benefits are significant. The enhanced durability reduces the frequency of repairs, replacements, and unexpected downtime. In high-power systems, preventing just one major failure can offset the initial investment.

Moreover, longer service intervals mean less need for costly maintenance. The total ownership cost of systems using heavy copper PCBs is often much lower than that of systems using standard PCBs. This cost efficiency makes them an appealing solution for industries requiring high performance and reliability.

Heavy Copper PCB as a Proven Solution for Failure Reduction

Heavy copper PCBs stand as a proven solution for reducing failure risks in power supply modules. Its superior current handling, thermal performance, and mechanical durability set it apart from traditional PCB designs. These advantages make it a vital component in various industries.