Current Trends in PCB Manufacturing You Need to Know for 2025

Printed circuit board technology continues to evolve rapidly. As 2025 approaches, PCB manufacturing faces both challenges and opportunities. Companies must track key trends to remain competitive and meet growing demands from the automotive, telecom, and consumer electronics sectors.

Shift Toward Advanced Materials

One of the most substantial shifts in PCB manufacturing is the adoption of advanced materials. High-frequency laminates, ceramic-filled substrates, and low-loss dielectrics are gaining traction. These materials improve signal integrity for 5G and data center applications. According to the Rogers Corporation, low-loss laminates significantly reduce transmission loss at high gigahertz frequencies. This makes them essential in radar, satellite, and telecom networks. As costs decline, more manufacturers are incorporating these substrates into mainstream production, thereby reshaping the PCB manufacturing landscape.

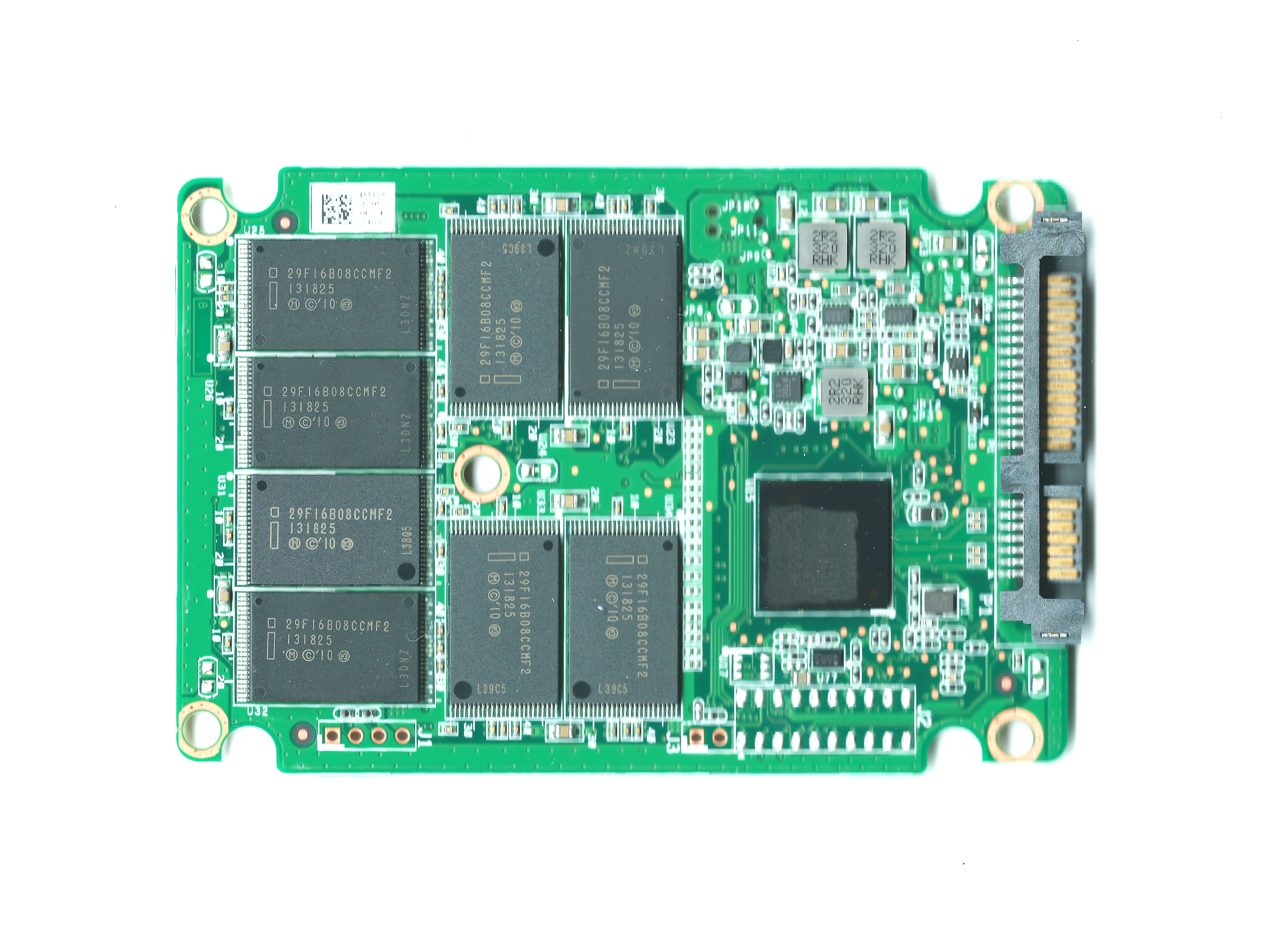

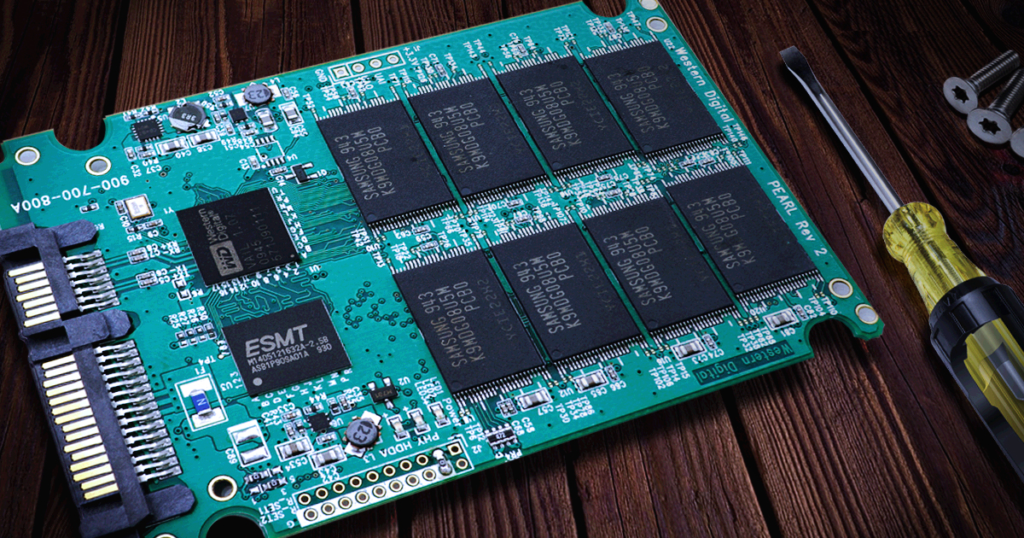

Growth of HDI and Miniaturization

Devices keep shrinking while functionality grows. High-Density Interconnect (HDI) technology enables finer lines and tighter spacing, supporting compact designs. Data from IPC shows that HDI adoption is growing fastest in mobile and wearable devices. Smaller vias, thinner dielectric layers, and stacked microvias enable more routing within a smaller space. This trend highlights how PCB manufacturing continues to prioritize higher-density packaging without compromising reliability.

Sustainability and Green Manufacturing Practices

Environmental responsibility has become a global priority. PCB manufacturers are now investing in eco-friendly processes, including lead-free finishes, water recycling, and energy-efficient plating. A report by Deloitte confirms that electronics companies adopting green supply chains reduce both regulatory risks and long-term costs. In Europe, stricter RoHS and REACH requirements are pushing firms to redesign processes. As a result, sustainable PCB manufacturing is no longer optional—it is essential for market access.

Automation and Smart Factories

Automation continues to transform production lines. Robotics and AI-driven inspection improve yield and cut defect rates. According to McKinsey, electronics plants using smart manufacturing increase efficiency by up to 30%. Real-time data monitoring also reduces downtime. Automated optical inspection (AOI) systems now detect micro-defects that the human eye misses. These changes enable PCB manufacturing to scale while maintaining consistent quality, particularly for complex multilayer boards.

Focus on High Frequency and 5G Applications

The rollout of 5G networks is reshaping the demand for PCBs. Boards must handle frequencies above 28 GHz with minimal loss. Materials such as PTFE composites and hybrid stack-ups are becoming standard. Keysight Technologies reports that poor PCB design is a leading cause of 5G device failures. To meet performance goals, manufacturers are refining etching, plating, and testing methods. The push for higher frequencies ensures that PCB manufacturing remains at the center of telecom innovation.

Regional Shifts in Production

Geopolitical and economic factors are changing global supply chains. While China remains the largest PCB producer, North America and Europe are regaining share through onshoring. The US CHIPS Act and EU funding programs support domestic electronics manufacturing. IPC highlights that companies are increasingly diversifying their suppliers to reduce risks. This trend impacts where investments flow, shaping the future structure of PCB manufacturing worldwide.

Integration of Embedded Components

Embedding passive and active components inside PCBs saves space and improves performance. This technique reduces parasitics, enhances power efficiency, and enables the fabrication of ultra-thin devices. Yole Développement forecasts strong growth in embedded PCB technology, particularly in automotive and IoT markets. By combining IC packaging and PCB processes, engineers streamline product design. As demand for smaller, more efficient electronics rises, embedded component technology will define a new era of PCB manufacturing.

Conclusion on PCB Manufacturing Trends

Advancements in materials, sustainability, automation, and high-frequency design shape the PCB industry in 2025. From HDI miniaturization to embedded components, each trend addresses specific market needs. Regional supply chain shifts further impact investment and strategy. Companies that adapt quickly to these trends will secure stronger market positions in the telecom, automotive, and consumer electronics sectors.