Why Gold Finger PCB Is Essential in Modular Electronics and Plug-in Devices?

Gold Finger PCB technology plays an essential role in modular electronics and plug-in devices. These specialized connectors enable stable and durable connections, ensuring seamless operation in demanding environments. In applications ranging from gaming systems to industrial machinery, the Gold Finger PCB ensures precise signal transmission and minimal electrical resistance.

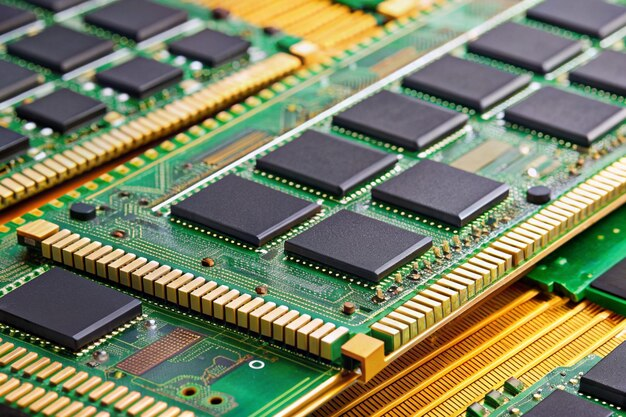

Enhancing Electrical Performance with Gold Finger PCB

One of the most significant advantages of the Gold Finger PCBs lies in their ability to enhance electrical performance. These connectors offer low contact resistance, enhancing current flow between components. This feature is critical for high-speed data transfer applications and power-intensive devices in complex environments.

Additionally, the gold plating on these connectors ensures long-lasting performance. Gold resists oxidation, which maintains a clean and conductive surface over time. As a result, the Gold Finger PCBs remain highly reliable, even in harsh or corrosive environments with fluctuating operational demands.

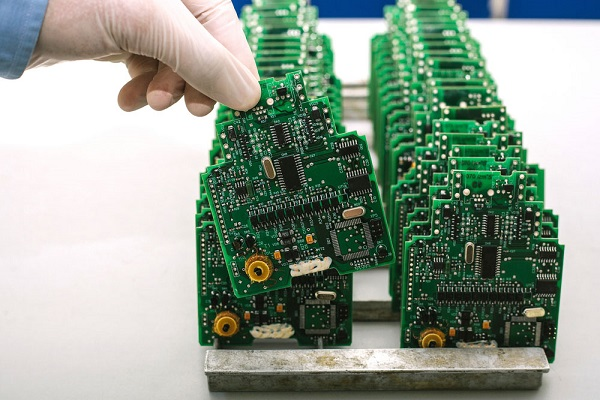

Durability and Wear Resistance in Demanding Applications

Durability is another key reason why manufacturers select the Gold Finger PCBs. In plug-in devices, connectors face frequent insertions and removals. Without robust materials, connections can quickly deteriorate, leading to performance failures that may result in costly system downtime.

Gold Finger PCB solutions are engineered to withstand this mechanical stress effectively. The gold plating, combined with precise manufacturing techniques, minimizes wear during usage. This durability reduces maintenance costs and extends the product’s operational life, making it an excellent choice for modular designs with rigorous performance needs.

Customization and Design Flexibility

Customization is a vital factor in PCB design, and the Gold Finger PCBs offer unmatched flexibility. Designers can adjust the length, width, and thickness of the gold fingers to meet specific application needs while also meeting specialized industry requirements.

Furthermore, engineers can specify the thickness of the gold plating to match expected usage levels. For instance, devices with frequent insertions may require thicker plating for enhanced durability. With Gold Finger PCB customization, manufacturers can fine-tune designs to strike a balance between cost, performance, reliability, and longevity for modular applications.

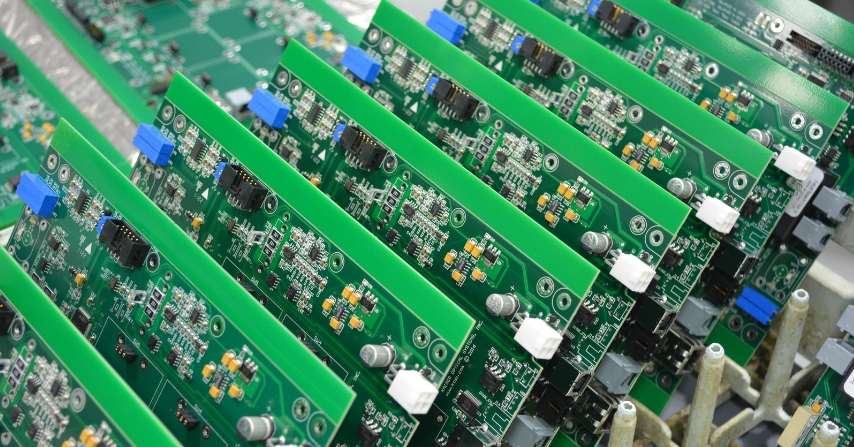

Simplifying Assembly and Maintenance Processes

Gold Finger PCBs connectors significantly simplify assembly processes. Their standardized designs allow for easy plug-and-play installation, reducing production time and minimizing assembly errors during large-scale production runs.

In addition, the Gold Finger PCBs streamline maintenance tasks. Users can easily replace or upgrade modules without specialized tools or technical expertise. This convenience makes the technology a preferred solution in industries that prioritize fast serviceability, minimal downtime, and modular upgrades for complex systems.

Compatibility Across a Broad Range of Applications

Versatility is another standout advantage of the Gold Finger PCBs. These connectors are compatible with various modular applications, from consumer electronics to aerospace systems, and they help reduce inventory complexity.

In industries like telecommunications and data centers, Gold Finger PCB designs enable high-reliability connections for critical systems. Their ability to support both power and signal transmission makes them indispensable in many sectors. This broad compatibility enables manufacturers to reduce design complexity while consistently meeting rigorous performance standards.

Meeting Industry Standards and Certifications

Gold Finger PCB designs must adhere to strict industry standards to ensure safety and interoperability. Certifications such as IPC-6012 and ISO standards validate the quality of these components across multiple markets.

Manufacturers benefit from sourcing Gold Finger PCB products from certified suppliers. This practice minimizes risks associated with product recalls or field failures. In regulated industries, such as the automotive or medical electronics sectors, adherence to standards is not only preferred but also mandatory to maintain compliance and reliability.

Maximizing Reliability with Gold Finger PCB

The Gold Finger PCBs stand as a cornerstone of modern modular electronics and plug-in devices. Its unmatched combination of electrical performance, durability, customization options, and versatility makes it an essential component for a wide range of industries. By integrating Gold Finger PCB technology, manufacturers can enhance product quality, simplify maintenance, and improve overall user experience.