Ceramic PCB and Their Role in High-Frequency Circuit Design

Ceramic PCBs have become essential in high-frequency circuit design. They outperform traditional PCBs due to their exceptional heat dissipation, electrical insulation, and mechanical stability. The Ceramic PCB is ideal for industries such as telecommunications, aerospace, automotive, and power electronics, where performance and reliability are crucial. As the demand for high-frequency devices, such as 5G communication systems, radar systems, and microwave circuits, grows, Ceramic Circuit Boards

have become even more important. These boards ensure reliable, efficient operation in high-performance circuits.

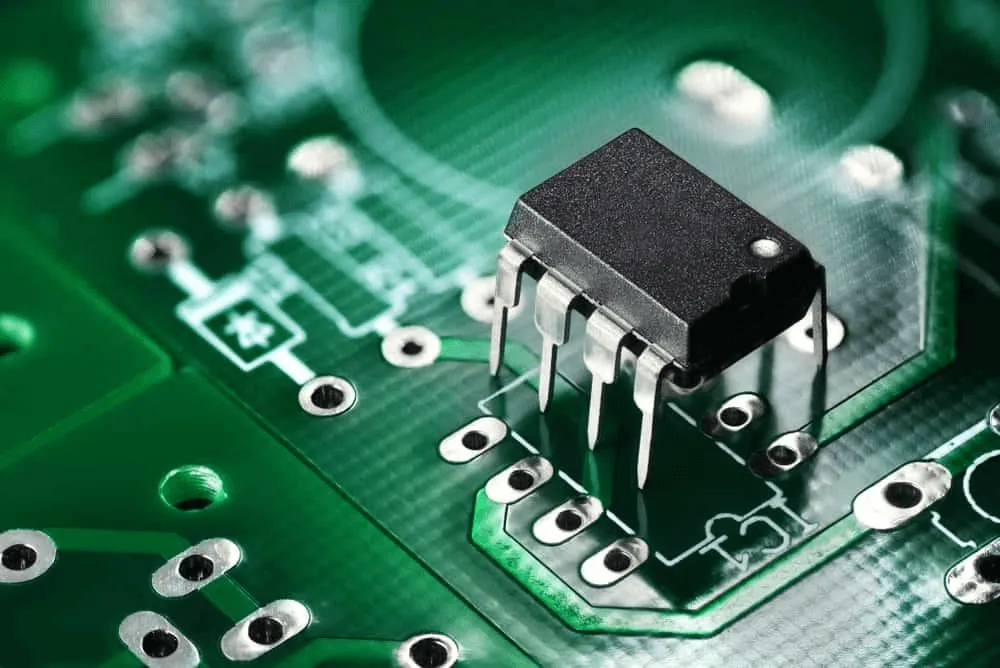

What Makes Ceramic PCB Unique?

Ceramic PCBs are made from materials like aluminum oxide (Al2O3) and boron nitride (BN). These materials provide exceptional thermal conductivity, making them ideal for high-frequency applications where heat dissipation is crucial. Unlike traditional PCBs, Ceramic PCBs excel at heat management. Their high thermal conductivity allows heat to transfer quickly, preventing overheating and ensuring consistent performance. Additionally, ceramic materials offer excellent electrical insulation. In high-frequency circuits, where maintaining signal integrity is critical, ceramic materials minimize signal loss and reduce electromagnetic interference (EMI). This ensures that Ceramic PCBs create a stable platform for high-performance designs.

Thermal Management in High-Frequency Circuits

Managing heat is crucial in high-frequency circuit design. These circuits generate significant heat, which can damage components if not properly managed. Ceramic PCBs help address this challenge. Their high thermal conductivity allows heat to spread quickly, preventing hot spots and minimizing the risk of component failure. This heat dissipation is vital in power amplifiers, radar systems, and satellite communication, where temperature stability is essential for optimal performance. The thermal management capabilities of Ceramic PCBs help maintain the longevity and reliability of electronic devices in high-frequency environments.

Electrical Insulation and Dielectric Properties of Ceramic PCB

In high-frequency circuits, materials need excellent electrical insulation to prevent signal degradation and short circuits. Ceramic Circuit Boards excel in this area due to their remarkable dielectric properties. The high dielectric strength of ceramics enables them to resist electrical breakdown, even under high-voltage conditions. This insulation ensures that high-frequency signals flow through the circuit without interference or loss of integrity. Additionally, ceramic materials exhibit low dielectric loss, which is crucial in high-frequency circuits. This feature minimizes energy loss, thereby improving the circuit’s overall efficiency. As a result, Ceramic PCBs help maintain signal quality and reliable performance in demanding environments.

Mechanical Stability: Durability and Strength in Harsh Environments

Ceramic materials offer remarkable mechanical stability, which makes Ceramic PCBs resistant to vibrations, shocks, and temperature fluctuations. This durability is vital in industries such as aerospace and automotive, where electronics must withstand extreme conditions. Traditional PCBs can crack or warp under stress, but Ceramic PCBs maintain their integrity even in harsh environments. This strength ensures that high-frequency circuits remain reliable and perform optimally in challenging conditions. Ceramic PCBs’ mechanical properties also allow for compact designs that do not sacrifice performance. Whether used in outdoor electronics, automotive systems, or industrial machinery, Ceramic PCBs offer the durability needed for long-lasting applications.

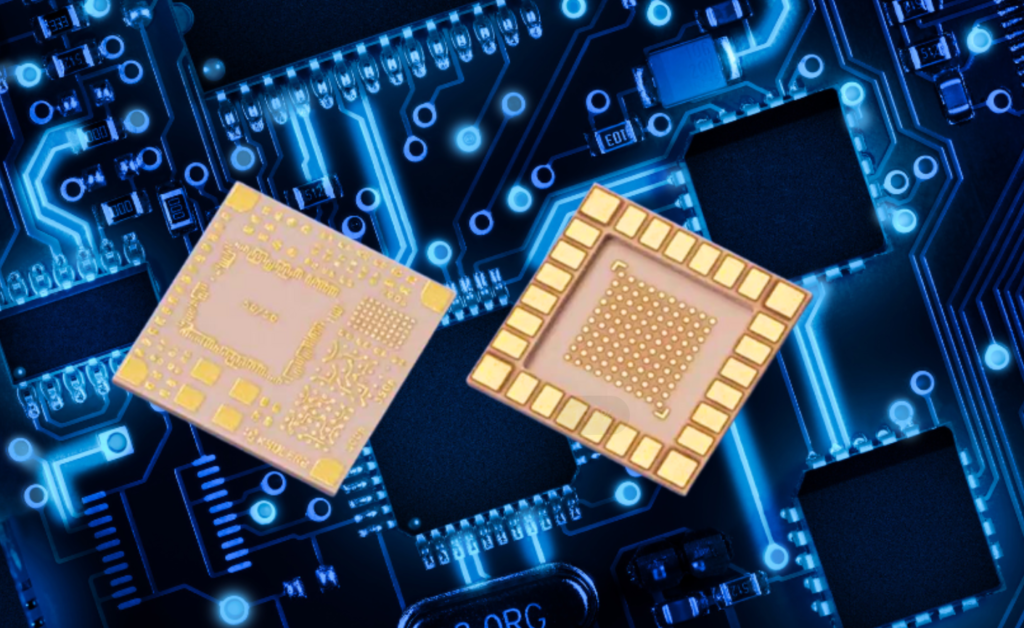

Manufacturing Process: How a Ceramic Circuit Board Is Made

The production of the Ceramic Circuit Board involves several precise steps. First, manufacturers prepare and process ceramic powders to create a fine, uniform material. Then, they mold the powder into substrates using pressing or injection molding techniques. After shaping the substrate, manufacturers sinter the ceramic material at high temperatures to enhance its strength and thermal conductivity. Once the ceramic substrate is ready, they apply conductive materials, such as copper, to its surface via sputtering, electroplating, or lamination. After the conductive layer is in place, manufacturers use etching, drilling, and electroplating to create circuit patterns and electrical pathways. Finally, electronic components are soldered onto the PCB, and quality control checks ensure the board meets the required specifications.

Applications of Ceramic PCB in High-Frequency Circuit Design

Ceramic PCBs are widely used in high-frequency applications where performance and reliability are critical. These include power amplifiers, radar systems, satellite communication equipment, and microwave circuits. Ceramic PCBs’ ability to handle high frequencies without signal degradation makes them ideal for technologies such as 5G and satellite communications. Their excellent thermal and electrical properties ensure that circuits operate efficiently in extreme conditions. Additionally, Ceramic PCBs enable the miniaturization of circuits, which is essential for portable devices and other space-constrained applications. As high-frequency technologies evolve, the demand for Ceramic PCBs will continue to grow, driven by the need for faster, more reliable electronic devices.