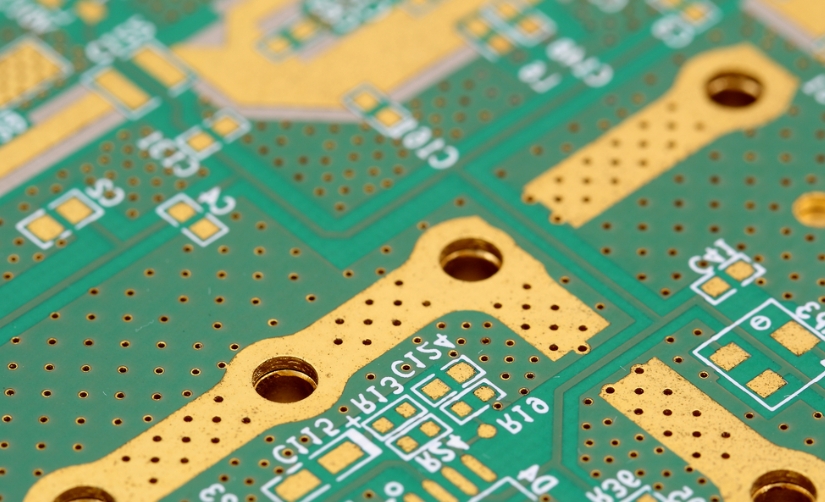

Why Heavy Copper PCB Is Gaining Traction in Power Electronics and EV Applications?

Power electronics and electric vehicles (EVs) demand higher efficiency and reliability. Engineers need boards that can handle extreme current loads without failure. This is where Heavy Copper PCB technology becomes essential. Unlike standard PCBs with thin copper layers, heavy copper designs use thicker copper foil to manage higher currents and improve thermal performance. Their growing adoption reflects both industry needs and proven benefits.

Increased Current Carrying Capacity

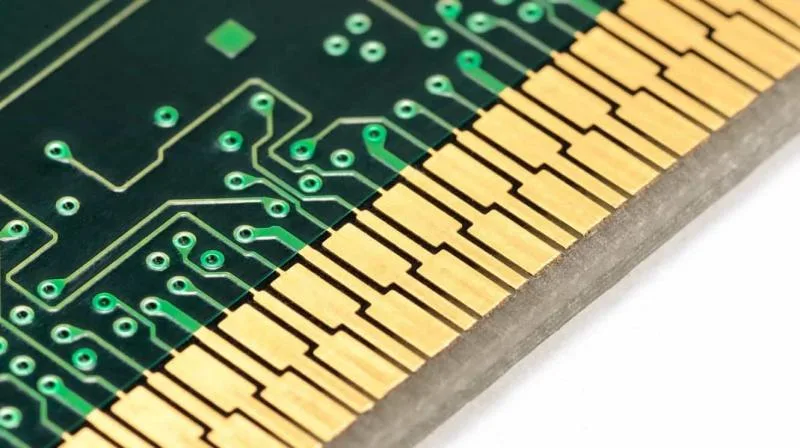

The primary reason for the rise of heavy copper PCBs is their ability to carry higher currents. Standard PCBs typically use 1 oz copper thickness, while heavy copper can range from 3 oz to 20 oz or more. According to IPC standards, a 10-oz copper trace can handle up to ten times more current than a standard 1-oz trace at the same width. This makes it suitable for inverters, converters, and power distribution units used in EVs and renewable energy systems.

Superior Thermal Management

Heat is one of the biggest challenges in power electronics. A heavy copper PCB improves heat dissipation by distributing thermal loads more evenly across the board. This reduces hotspots and prevents premature component failure. For example, data from the International Energy Agency shows that EV battery packs must operate within narrow temperature ranges to ensure performance. Heavy copper circuits help stabilize thermal conditions, thereby extending the system’s lifespan.

Durability and Reliability in Harsh Environments

Automotive and industrial systems face challenging conditions, ranging from vibrations to extreme temperature fluctuations. Heavy Copper PCB designs enhance mechanical strength and ensure connections remain stable. Studies published by IEEE highlight that the thickness of copper directly impacts fatigue resistance in high-vibration environments. This reliability is one of the reasons automakers integrate heavy copper into on-board chargers and motor drive controllers.

Cost Efficiency Over the Product Lifecycle

At first glance, the Heavy Copper PCB appears more expensive due to its material and fabrication requirements. However, it often reduces costs over the product lifecycle. Fewer layers are needed to achieve the same performance as multi-layer standard boards. Maintenance costs decrease due to more extended durability and fewer breakdowns. In the EV sector, downtime translates into significant financial losses, making reliability a cost saver rather than an expense.

Support for Compact and High-Density Designs

Modern power electronics demand compact designs without sacrificing performance. Heavy copper PCBs enable engineers to shrink board size while still supporting high current paths. According to MarketsandMarkets, the global EV power electronics market is projected to grow at a CAGR of over 20% through 2030. To meet this demand, compact and efficient heavy copper solutions are becoming the norm.

Key Applications in EV and Power Electronics

Heavy copper PCBs play a central role in EV traction inverters, battery management systems, and DC-DC converters. In renewable energy, it supports wind turbine controllers and solar inverters. Industrial automation also benefits from heavy copper technology, especially in motor drives and robotics. These real-world applications prove that heavy copper is not just a niche solution but a mainstream requirement in high-power systems.

Sustainability and Energy Efficiency Benefits

The shift toward sustainable energy is another driver. Heavy copper PCBs reduce energy loss by minimizing resistance in high-current paths. This improves overall system efficiency. In EV charging stations, for example, efficiency improvements reduce wasted energy and lower operating costs. Reports from the U.S. Department of Energy indicate that even a 1–2% increase in power conversion efficiency can have a significant impact when scaled across thousands of charging points.

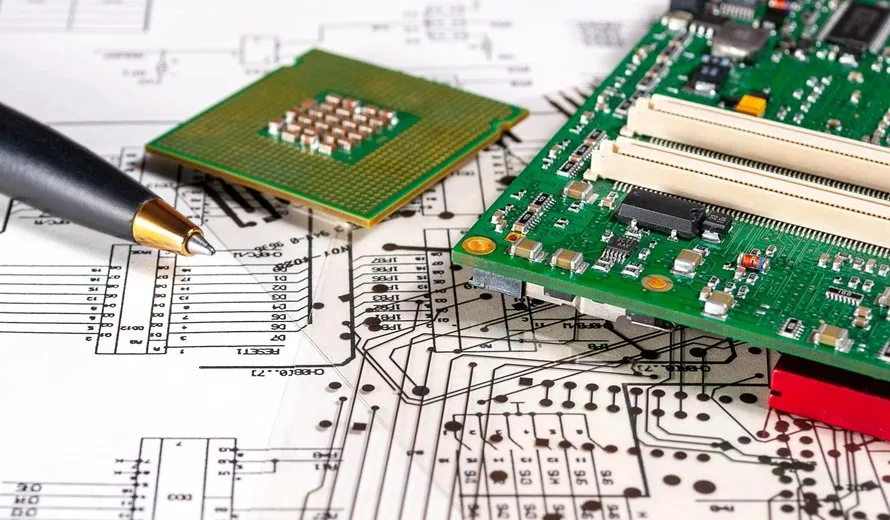

Future Outlook for Heavy Copper PCB

The demand for heavy copper PCBs will continue to grow with the expansion of EV infrastructure, renewable power, and high-performance computing. Manufacturers are investing in advanced fabrication methods, such as laser direct structuring and improved etching processes, to handle thicker copper without compromising precision. As industry standards evolve, heavy copper technology will continue to be a cornerstone of reliable, efficient, and compact power solutions.